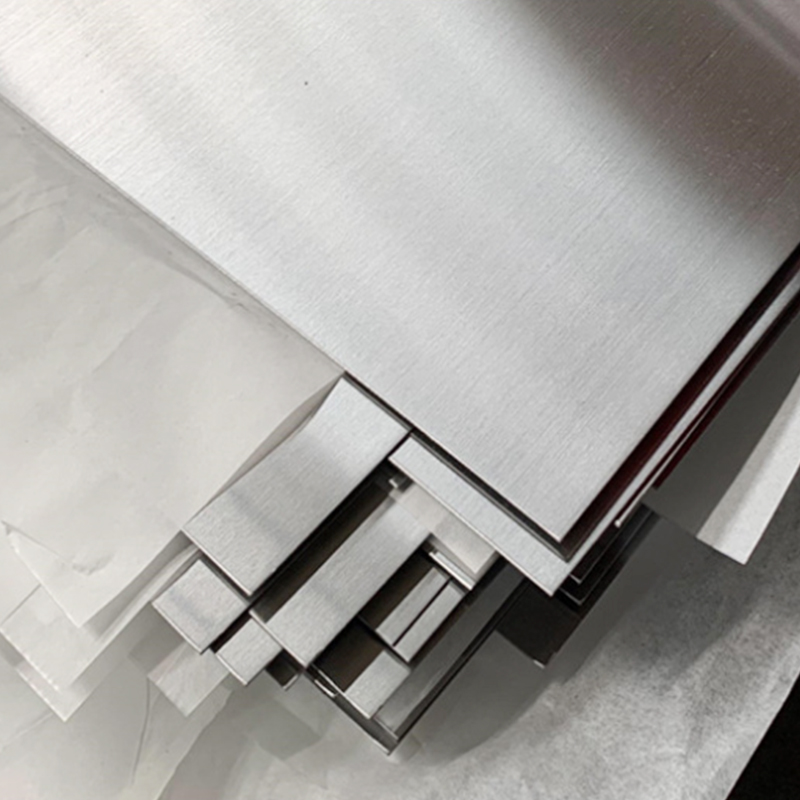

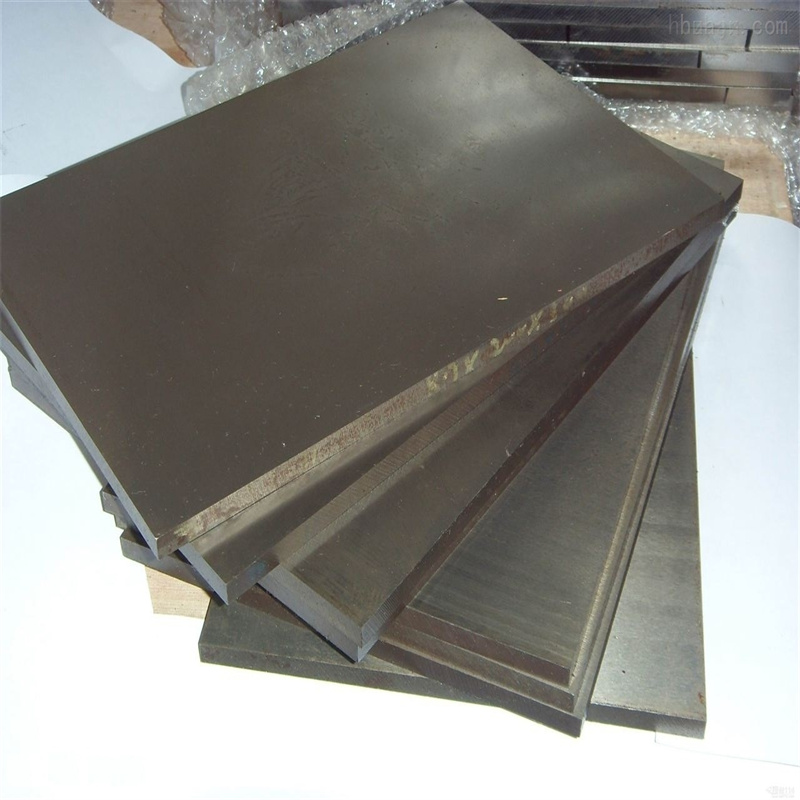

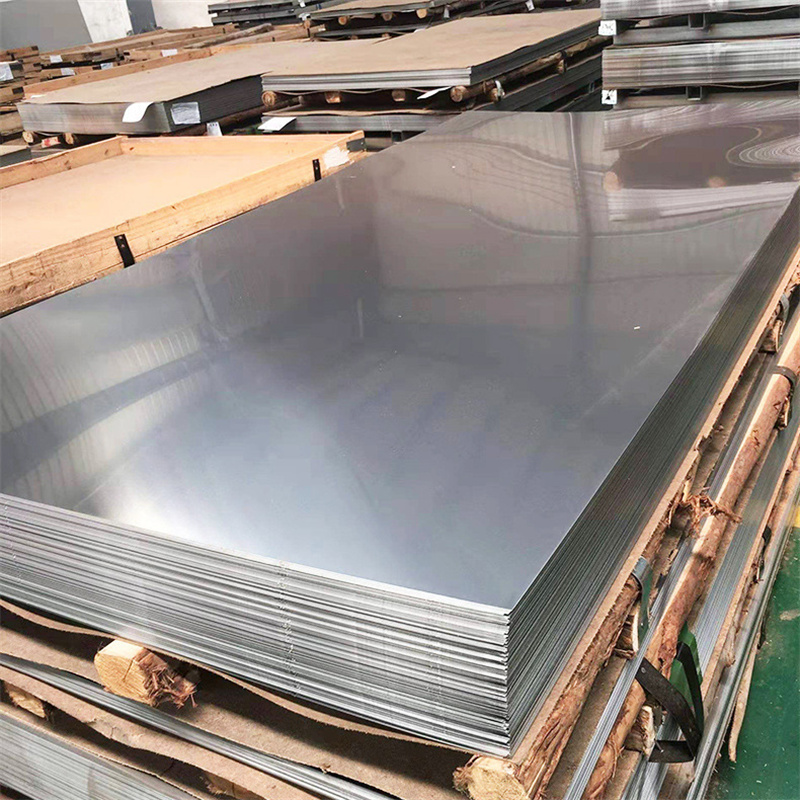

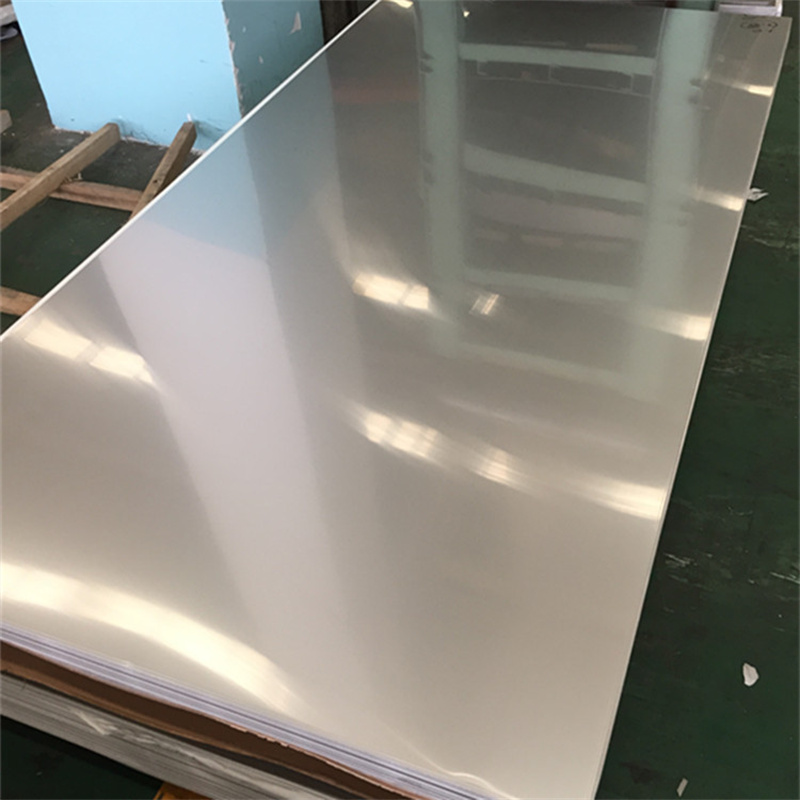

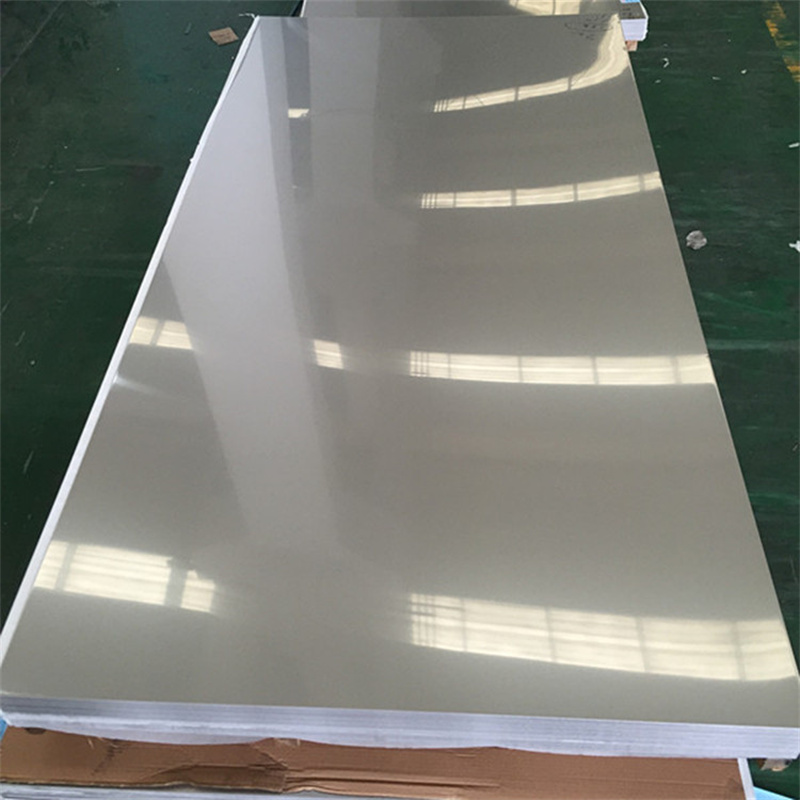

GH3030 plate

GH3030 plate is a high-performance nickel-based alloy that offers exceptional resistance to high temperatures and corrosion. It is widely used in aerospace, chemical processing, and other high-end industries that require materials with exceptional thermal and chemical properties.

Resistance to high temperatures: GH3030 plate has excellent resistance to high temperatures, making it suitable for use in extreme heat environments. It can withstand temperatures up to 1000°C without compromising its mechanical properties.

Corrosion resistance: The nickel-based alloy of GH3030 plate provides excellent resistance to corrosion, making it suitable for use in harsh chemical environments. It is highly resistant to acids, alkalis, and other corrosive substances.

High strength: GH3030 plate offers good mechanical properties, including high tensile strength and yield strength. It maintains its strength even at elevated temperatures, making it suitable for use in structural applications.

Good thermal stability: The alloy has excellent thermal stability, meaning it can withstand repeated exposures to high temperatures without significant degradation. This makes it an ideal material for applications that require frequent exposure to extreme heat.

Easy processing: GH3030 plate is easy to process, making it a cost-effective material choice. It can be easily machined, welded, and formed into various shapes and sizes.

GH3030 plate is used in a wide range of industries due to its exceptional thermal and corrosion resistance properties. Some common applications include:

Aerospace components: The high-temperature resistance of GH3030 plate makes it suitable for use in aircraft engines and other critical components that require resistance to extreme heat.

Automotive components: The corrosion resistance of GH3030 plate allows it to be used in automotive exhaust systems and other components that are exposed to harsh chemical environments.

Energy industry: The material is commonly used in heat exchangers, boiler components, and other equipment in the energy industry due to its exceptional thermal stability.

Chemical processing equipment: GH3030 plate is often used in the manufacturing of chemical processing equipment, such as reactors and piping systems, due to its corrosion resistance and high-temperature capabilities.

With its exceptional combination of high-temperature resistance, corrosion resistance, and good mechanical properties, GH3030 plate is a highly versatile material that finds applications across various industries. Its ease of processing and cost-effectiveness make it a preferred choice for many manufacturing applications that require materials that can withstand extreme heat and harsh chemical environments.

| Product Name: GH2132 Plate |

| Ni | Cr | Co | Mo | Ti | Al | C | P | S | Fe | Cu |

| ≥52.0% | ≥19.0% | 10%-12% | 2%- 3% | 0.5%-1% | ≤0.5% | ≤0.08% | ≤0.02% | ≤0.015% | ≤18.0% | ≤0.5% |

| Mechanical Properties | GH3030 Plate exhibits good tensile strength, creep resistance, and fatigue strength, making it suitable for use in high-temperature applications. The material has a minimum yield strength of 170ksi at room temperature and a maximum tensile strength of 220ksi at elevated temperatures. |

| Thermal Properties | GH3030 Plate has a melting range of 1260°C to 1350°C and a coefficient of thermal expansion of approximately 14 cm/cm/°C in the temperature range from room temperature to 982°C. |

| Corrosion Resistance | GH3030 Plate is highly resistant to oxidation and corrosion, making it suitable for use in acidic and caustic environments. The material also exhibits good resistance to sulfurization and carburization. |