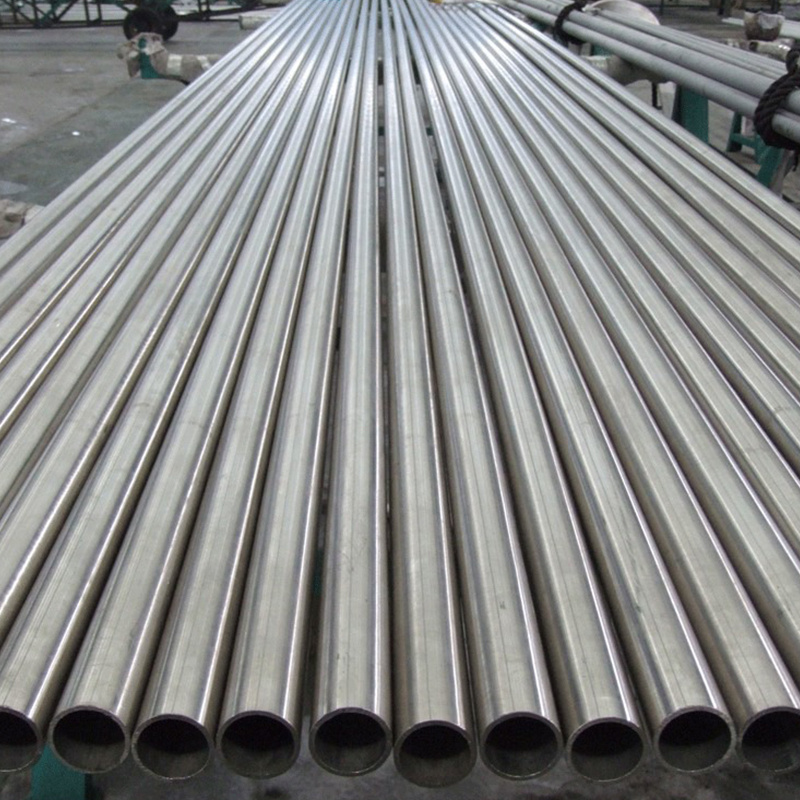

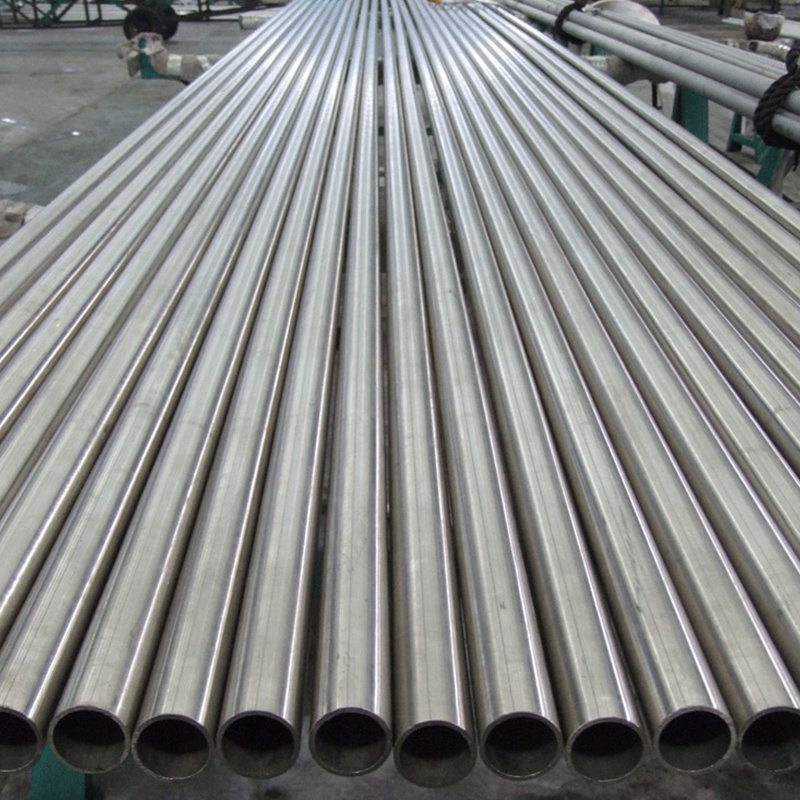

GH3039 Pipe

GH3039 pipe is a high-performance nickel-based alloy, widely used in a range of demanding applications due to its exceptional combination of high temperature strength, corrosion resistance, and good weldability.

GH3039 pipe is commonly used in aerospace, power generation, and chemical processing industries due to its ability to withstand extreme temperatures and corrosive environments. It offers excellent mechanical properties at high temperatures, making it an ideal material for components that are exposed to heat and pressure.

The chemical composition of GH3039 pipe is carefully balanced to provide a unique combination of properties. It contains nickel as the primary element, along with chromium, iron, and other alloying elements. The nickel content provides excellent corrosion resistance, while the chromium adds strength and stability at high temperatures.

GH3039 pipe is produced using a carefully controlled hot extrusion process. This process ensures that the material has a fine grain structure, which improves its mechanical properties. The pipe is also heat treated to ensure that it meets the required mechanical properties and dimensional tolerances.

GH3039 pipe is used in a wide range of applications due to its exceptional combination of properties. Some of the common applications include:

Power generation plants - Used in the manufacturing of components for boiler systems, heat exchangers, and other critical components that require resistance to high temperatures and corrosion.

Aerospace industry - Used in the manufacturing of airframe components, engine components, and other critical parts that require high strength and stability at high temperatures.

Chemical processing industry - Used in the manufacturing of piping systems, reactors, and other process equipment that require resistance to corrosion and high temperatures.

Automotive industry - Used in the manufacturing of exhaust systems and other components that require resistance to corrosion and high temperatures.

GH3039 pipe offers a unique combination of properties that make it suitable for use in demanding applications that require resistance to high temperatures, corrosion, and good mechanical properties. Its wide range of applications across various industries highlights its versatility and adaptability in different environments.

| Product Name: GH2132 Pipe |

| Chemical Composition |

| C | Cr | Ni | Al | Ti | Mo | Nb |

| ≤0.08 | 19.0~22.0 | Balance | 0.35~0.75 | 0.35~0.75 | 1.80~2.30 | 0.90~1.30 |

| Fe | Si | S | Mn | P |

| ≤3.00 | ≤0.80 | ≤0.012 | ≤0.40 | ≤0.02 |

| Mechanical Properties |

Tensile strength at room temperature: ≥ 800 MPa |

| Tensile strength at high temperature: ≥ 550 MPa | |

| Yield strength at room temperature: ≥ 340 MPa | |

| Reduction of area: ≥ 55% | |

| Impact toughness: ≥ 80 J (180°C) | |

| Hardness: HRB ≤ 90 |