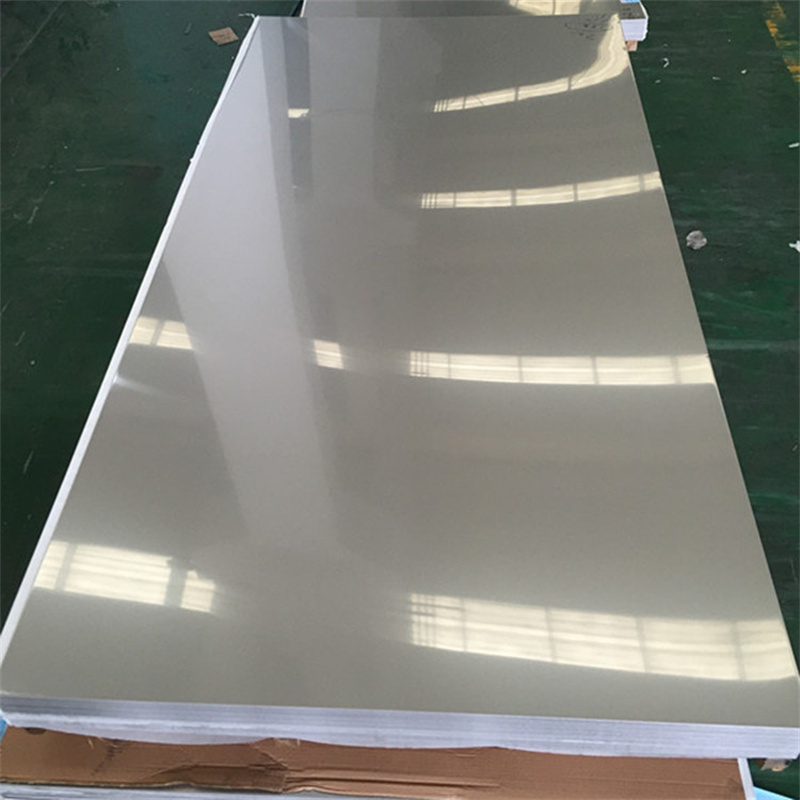

GH3128 Plate

GH3128 is a high-temperature alloy, specifically designed for use in extreme environments. It is a nickel-based alloy, making it highly resistant to high temperatures and corrosive environments. The plate form of GH3128 is particularly suitable for use in a range of industrial applications, including power generation, oil and gas production, and aerospace.

1.High Temperature Resistance: GH3128 plate has excellent high-temperature strength, making it suitable for use in environments where temperatures may reach or exceed 1300°C. This exceptional heat resistance is achieved through the alloy's unique composition, which includes significant amounts of chromium, tungsten, and niobium.

2.Corrosion Resistance: The nickel-based composition of GH3128 provides excellent resistance to a range of corrosive environments, including oxidizing conditions at high temperatures. This makes the material particularly suitable for use in harsh industrial environments where exposure to acids, alkalis, or other corrosive substances is common.

3.High Strength: GH3128 plate has excellent tensile strength and creep resistance even at elevated temperatures. This makes it an excellent choice for structural components that require stability and durability under load.

4.Easy Fabrication: GH3128 plate can be easily machined, welded, and formed into a variety of shapes and sizes. This versatility in processing makes it an attractive material choice for fabricating components with complex geometries.

5.Long Service Life: Due to its exceptional resistance to high temperatures and corrosion, GH3128 plate has a long service life. It can withstand repeated exposure to extreme conditions without significant degradation, reducing the need for frequent maintenance or replacement.

GH3128 plate is widely used in a range of industries where high temperatures and corrosive environments are common. Some of the key applications include:

1.Power Generation: In power plants, GH3128 plate is used in heat exchangers, boiler components, and other high-temperature equipment due to its exceptional heat resistance and corrosion resistance.

2.Oil and Gas Production: In the oil and gas industry, GH3128 plate is used in pipelines, valves, and other critical components that must withstand high temperatures and corrosive environments.

3.Aerospace: In the aerospace industry, GH3128 plate is used in jet engines and other critical components that require high-temperature strength and corrosion resistance.

4.Automotive: In the automotive industry, GH3128 plate is used in exhaust systems and other components that must withstand high temperatures and corrosive exhaust gases.

5.Chemical Processing: In the chemical processing industry, GH3128 plate is used in reactors, vessels, and other components that must resist corrosion and maintain structural integrity under extreme conditions.

In conclusion, GH3128 plate offers a unique combination of high-temperature strength, corrosion resistance, and ease of fabrication. Its wide range of applications across multiple industries makes it a valuable material choice for engineers and designers who require durability and performance in extreme environments.

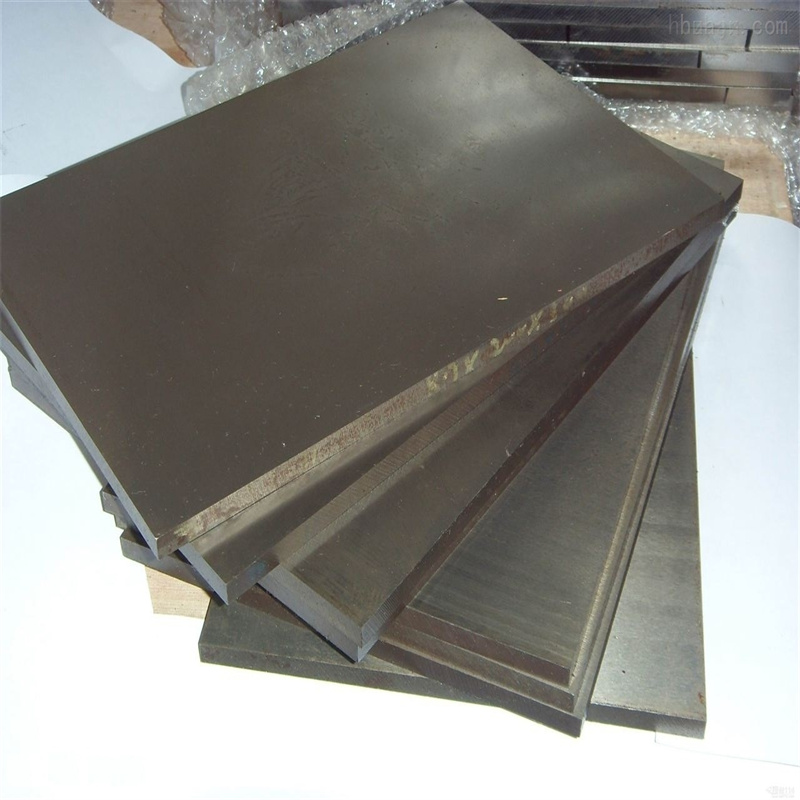

GH3128's ability to maintain its mechanical properties at elevated temperatures is further enhanced by its oxidation resistance. The material forms a protective oxide scale on its surface, preventing further oxidation and corrosion. This scale also acts as a thermal barrier, reducing heat transfer and helping to maintain the material's mechanical properties even under extreme conditions.

The versatility of GH3128 extends beyond its exceptional chemical and mechanical properties. The material is also easy to process, making it an attractive choice for manufacturing applications. It can be fabricated using conventional techniques such as casting, forging, and machining, without the need for specialized processing equipment.

| Product Name: GH3128 Plate |

| Chemical Composition |

| C | Cr | Ni | W | Mo | Al | Ti |

| ≤0.05 | 19.0~22.0 | Balance | 7.5~9.0 | 7.5~9.0 | 0.40~0.80 | 0.4~0.80 |

| Fe | B | Zr | Ce | Mn | Si | P | S |

| ≤ | ≤ | ≤ | ≤ | ≤ | ≤ | ≤ | ≤ |

| 0.2 | 0.005 | 0.06 | 0.05 | 0.50 | 0.80 | 0.013 | 0.013 |