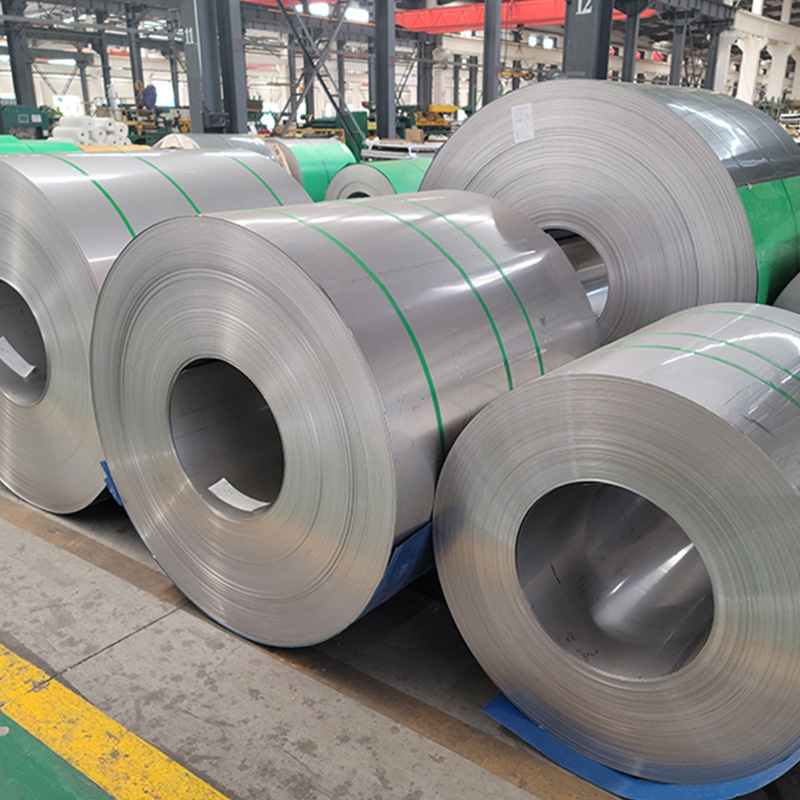

GH4145 Coil

GH4145 Coil is a high-performance metallurgical product, designed for use in a wide range of demanding applications. With its exceptional combination of properties, GH4145 Coil offers unparalleled performance in terms of tensile strength, corrosion resistance, and fatigue resistance.

The unique properties of GH4145 Coil are achieved through its nickel-based alloy composition. GH4145 contains a high percentage of nickel, along with additions of chromium, aluminum, and titanium. These elements combine to create a material that is highly resistant to corrosion, making it suitable for use in harsh environments.

GH4145 Coil offers excellent tensile strength, meaning it can withstand high tensile loads without failure. This makes it an excellent choice for applications where components are exposed to high stress or fatigue loads, such as in aircraft and aerospace manufacturing.

Another key advantage of GH4145 Coil is its exceptional fatigue resistance. Fatigue resistance is crucial in applications where components are repeatedly loaded and unloaded, such as in automotive and transportation industries. GH4145 Coil's ability to withstand fatigue loading means it can significantly increase the service life of components, reducing the need for premature replacement.

GH4145 Coil is also highly heat-resistant, making it suitable for use in high-temperature applications. It can withstand temperatures up to 1300°F (700°C), making it suitable for use in industrial furnaces, power generation equipment, and other high-temperature systems.

In addition to its exceptional physical properties, GH4145 Coil is also easy to fabricate and weld, making it compatible with various manufacturing processes. It can be bent, cut, and formed into various shapes and sizes, making it versatile for a wide range of applications.

GH4145 Coil is also highly versatile in terms of its end-use industries. It is widely used in the aerospace, automotive, power generation, chemical processing, and other industries that require high-performance materials.

In conclusion, GH4145 Coil is a high-performance metallurgical product that offers exceptional tensile strength, corrosion resistance, fatigue resistance, and heat resistance. Its unique combination of properties makes it an excellent choice for use in a wide range of demanding applications across various industries.

| Product Name: GH4145 Coil |

| Chemical Composition |

| C | Cr | Ni+Co | Al | Ti | Fe | Nb+Ta |

| ≤0.08 | 14.0~17.0 | ≥70.0 | 0.40~1.00 | 2.25~2.75 | 5.00~9.00 | 0.70~1.20 |

| Co | Mn | Si | S | Cu | P |

| ≤1.00 | ≤0.35 | ≤0.35 | ≤0.010 | ≤0.50 | ≤0.015 |

| Mechanical Properties |

| GH4145 exhibits good tensile strength, creep resistance, and fatigue strength. It has a tensile strength ranging from 80 ksi to 120 ksi (approximately 550 MPa to 820 MPa) and a yield strength of approximately 50 ksi (340 MPa). The material also exhibits good cold workability and can be processed through various cold-working techniques to achieve desired mechanical properties. |

| Corrosion Resistance |

| GH4145 has excellent resistance to oxidation and corrosion, making it suitable for use in high-temperature and corrosive environments. It has good resistance to acids, alkalis, and various corrosive gases. However, it should be noted that the material may require special surface coatings or treatments to enhance its corrosion resistance in certain environments. |

| Processing and Fabrication |

| GH4145 can be processed through various techniques, including forging, casting, and powder metallurgy. It can also be welded using appropriate welding procedures. However, due to its high melting temperature and reactivity, special melting and processing techniques are required to ensure the material's integrity and properties. Fabrication of GH4145 parts requires strict controls to ensure dimensional accuracy and mechanical properties. |