GH4145 Pipe

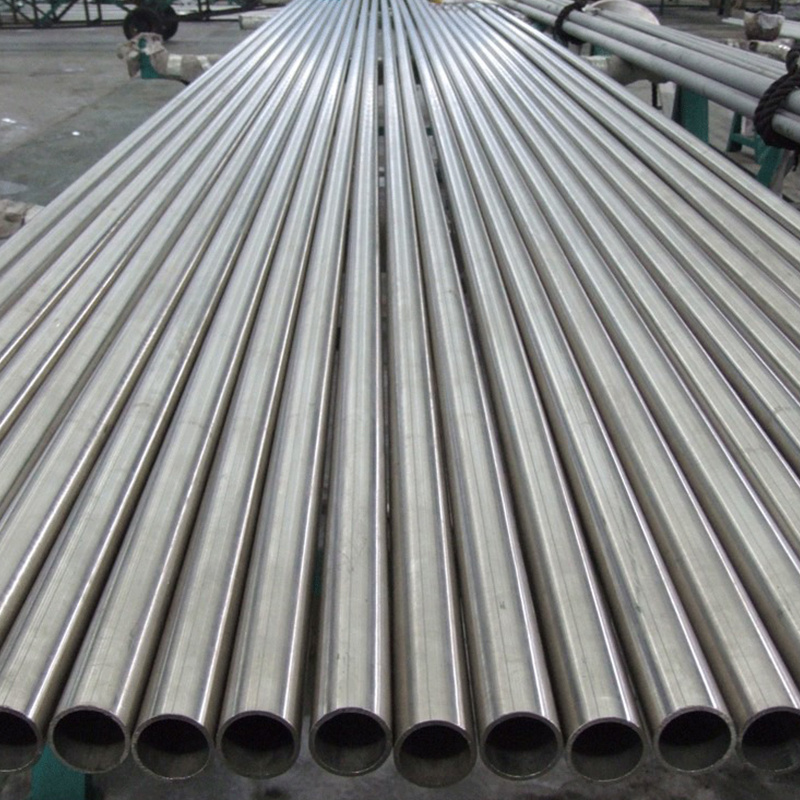

GH4145 Pipe, a high-performance nickel-based alloy, offers superior strength and exceptional corrosion resistance. This pipe, used in a wide range of industries, is a valuable addition to any material handling system.

GH4145 Pipe is renowned for its exceptional tensile strength and yield strength, making it an ideal choice for extreme applications. Whether you're working in high-temperature environments or under conditions that demand exceptional durability, GH4145 Pipe will stand the test of time. Its unique properties are further enhanced by its excellent resistance to acids and other corrosive agents, making it an ideal choice for use in chemical processing plants and other industries where corrosion resistance is paramount.

This pipe also offers excellent resistance to creep, ensuring its dimensional stability even under extreme pressure and temperature. This makes it an excellent choice for use in high-pressure piping systems, such as those found in the oil and gas industry.

GH4145 Pipe's exceptional properties are the result of its carefully formulated composition. The alloy contains a unique combination of elements that promote its strength and corrosion resistance, making it a highly versatile material. It can be used in both welded and seamless forms, providing flexibility in design and installation.

In addition to its performance advantages, GH4145 Pipe is also easy to fabricate and install. Its weldability and ease of processing make it an economical choice for a wide range of industrial applications. Its compatibility with various joining methods further simplifies installation and repair.

GH4145 Pipe is a prime example of high-performance materials technology. Its combination of strength, corrosion resistance, and ease of processing makes it a valuable asset in various industries where performance and durability are critical. Whether you're looking to improve the efficiency of your current operations or need a pipe that will stand the test of time, GH4145 Pipe is the perfect choice.

| Product Name: GH4145 Pipe |

| Chemical Composition |

| C | Cr | Ni+Co | Al | Ti | Fe | Nb+Ta |

| ≤0.08 | 14.0~17.0 | ≥70.0 | 0.40~1.00 | 2.25~2.75 | 5.00~9.00 | 0.70~1.20 |

| Co | Mn | Si | S | Cu | P |

| ≤1.00 | ≤0.35 | ≤0.35 | ≤0.010 | ≤0.50 | ≤0.015 |

| Mechanical Properties | GH4145 pipe exhibits high strength, ductility, and fatigue resistance. It has excellent creep resistance at elevated temperatures, making it suitable for use in severe service conditions. The tensile strength of GH4145 pipe ranges from 980 to 1370 MPa, depending on the heat treatment and processing conditions. |

| Corrosion Resistance | GH4145 pipe has excellent corrosion resistance in a wide range of environments, including oxidizing and reducing acids, chloride solutions, and high-temperature sulfide-containing gases. Its high chromium content provides resistance to pitting and crevice corrosion, while the molybdenum and titanium alloying elements enhance resistance to general corrosion and stress corrosion cracking. |

| Thermal Properties | GH4145 pipe has good thermal conductivity and a low coefficient of thermal expansion. It has a melting range of 1315°C to 1370°C and can withstand temperatures up to 980°C in continuous service. |

| Fabrication | GH4145 pipe can be fabricated using various processes, including welding, brazing, and soldering. However, care must be taken during processing to avoid excessive heating, which can cause loss of mechanical properties. Pipe made from GH4145 is also available in seamless and welded configurations, depending on the specific application requirements. |