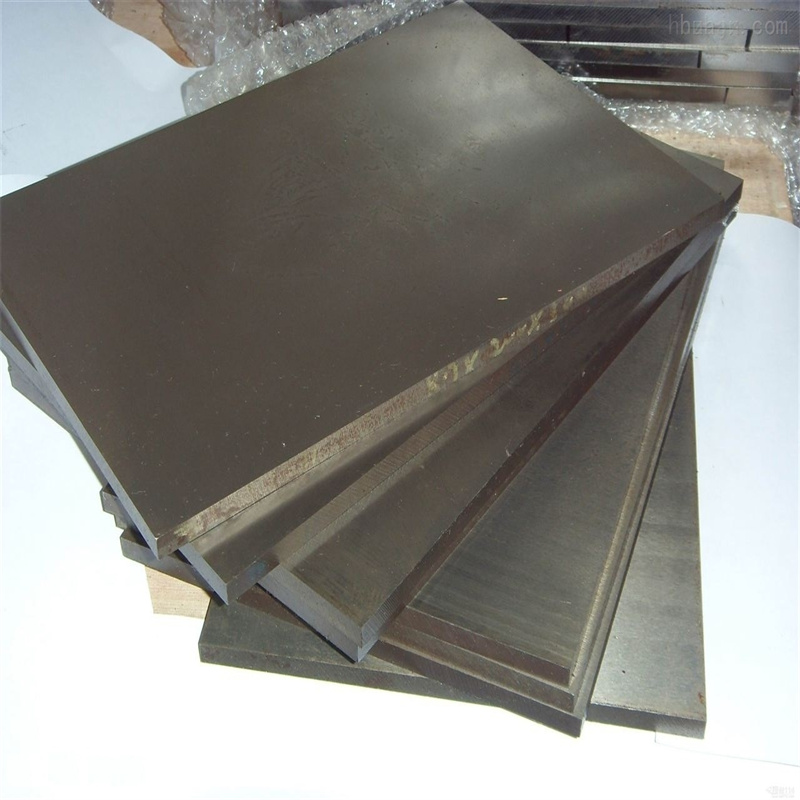

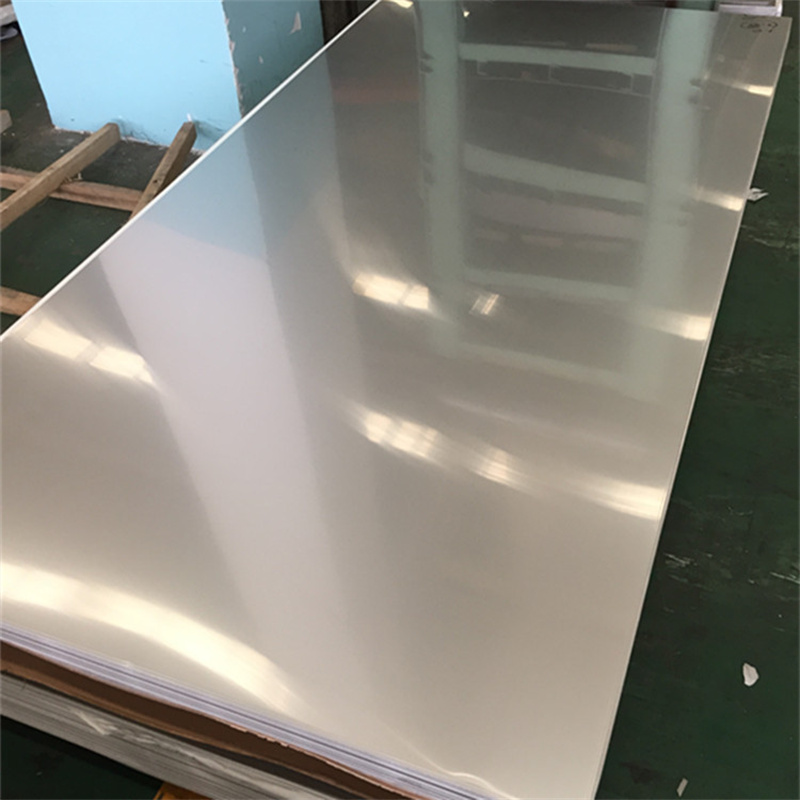

GH4145 Plate

GH4145 plate, also known as Inconel 718, is a high-performance nickel-based alloy that finds applications in a wide range of extreme environments. Characterized by its exceptional corrosion resistance and high-temperature strength, GH4145 plate is often the material of choice in industries like aerospace, oil and gas, and chemical processing.

GH4145 plate exhibits excellent mechanical properties, making it suitable for use in demanding applications. Some of the key properties of GH4145 plate include:

High Strength: GH4145 plate offers excellent tensile strength and yield strength, making it capable of withstanding heavy loads and extreme pressures.

Corrosion Resistance: The nickel-based alloy has excellent resistance to acids, alkalis, and various corrosive environments, making it well-suited for use in harsh chemical processing applications.

High-Temperature Performance: GH4145 plate maintains its mechanical properties even at elevated temperatures, making it suitable for use in high-temperature environments.

Good Weldability: The alloy can be easily welded using common welding techniques, making it easy to fabricate and repair components made from GH4145 plate.

GH4145 plate is used in a variety of applications due to its unique combination of properties. Some common applications include:

Aerospace Components: GH4145 plate is used to fabricate critical components in aircraft engines, landing gear, and other aerospace structures that require high strength and corrosion resistance.

Oil and Gas Exploration and Production: The alloy is commonly used in the oil and gas industry for the fabrication of wellheads, pipelines, and other components that must withstand harsh environments.

Chemical Processing Equipment: GH4145 plate is used in the manufacturing of chemical processing equipment, such as reactors and tanks, due to its exceptional corrosion resistance.

Fabrication of GH4145 plate requires special considerations due to its unique properties. Some key aspects of processing GH4145 plate include:

Hot Working: The alloy is hot worked above its recrystallization temperature to achieve the desired shape and properties. Care must be taken to avoid overheating or cooling the material too quickly, as this can affect its microstructure and properties.

Welding: Welding of GH4145 plate is performed using appropriate filler metals and welding procedures to ensure the integrity of the weld joint. Post-weld heat treatment may be required to restore the material's properties.

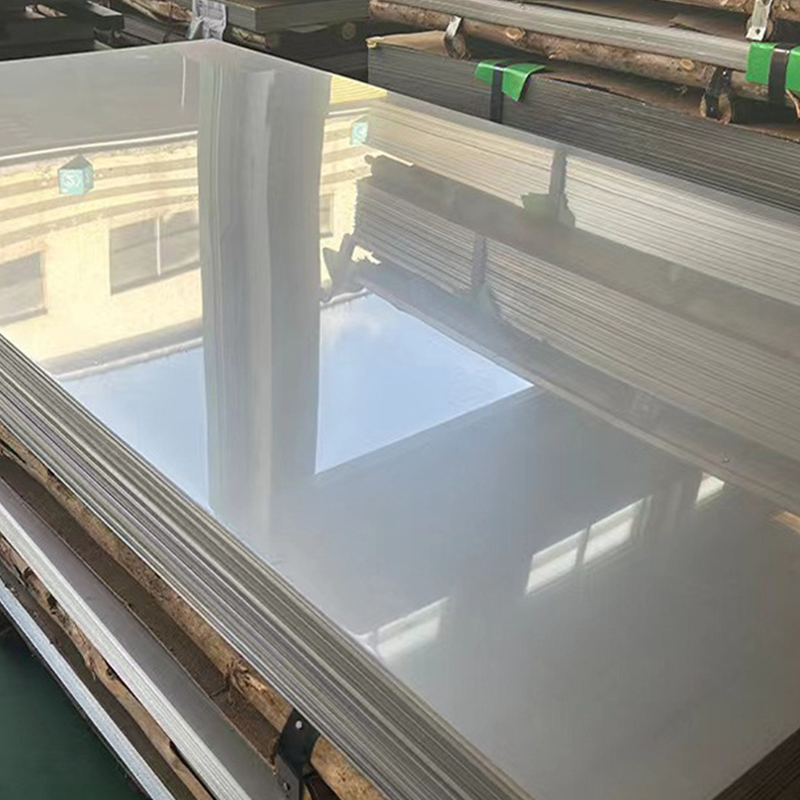

Surface Treatment: Surface finishes and coatings can be applied to GH4145 plate to enhance its corrosion resistance or provide additional functionalities. Common surface treatments include anodizing, galvanizing, and thermal spraying.

Proper repair and maintenance of GH4145 plate are essential to maintaining its longevity and performance. Some key considerations for the repair and maintenance of GH4145 plate include:

Regular Inspections: Regular inspections are essential to identify any signs of corrosion or damage to the plate. Close attention should be paid to areas that are prone to corrosion or stress concentration.

Corrosion Repair: If corrosion is detected, prompt repair is essential to prevent further damage. Corrosion repair procedures may involve cleaning, surface preparation, and application of corrosion-resistant coatings or platings.

Welding Repairs: Welding repairs should be performed by experienced personnel using appropriate welding procedures and materials to ensure the integrity of the repair. Post-weld heat treatment may be required to restore the material's properties.

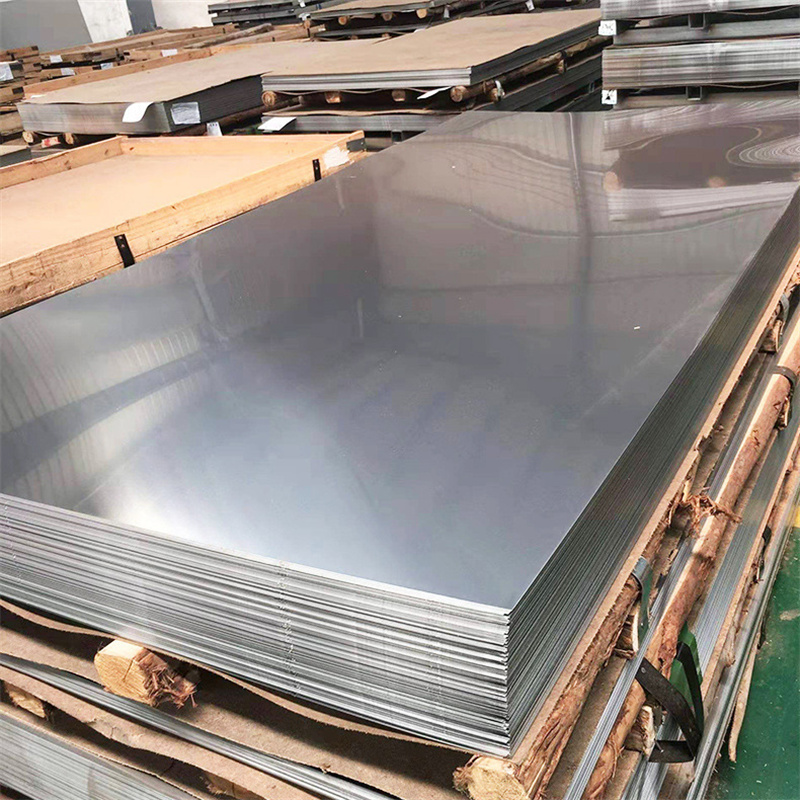

Proper storage and handling are essential to maintaining the integrity of GH4145 plate. Some key considerations for the storage and handling of GH4145 plate include:

Storage Environment: The alloy should be stored in a clean, dry environment to prevent corrosion. Avoid exposure to extreme temperatures, as this can affect the material's properties.

GH3128's ability to maintain its mechanical properties at elevated temperatures is further enhanced by its oxidation resistance. The material forms a protective oxide scale on its surface, preventing further oxidation and corrosion. This scale also acts as a thermal barrier, reducing heat transfer and helping to maintain the material's mechanical properties even under extreme conditions.

The versatility of GH3128 extends beyond its exceptional chemical and mechanical properties. The material is also easy to process, making it an attractive choice for manufacturing applications. It can be fabricated using conventional techniques such as casting, forging, and machining, without the need for specialized processing equipment.

| Product Name: GH4145 Plate |

| Chemical Composition |

| C | Cr | Ni+Co | Al | Ti | Fe | Nb+Ta |

| ≤0.08 | 14.0~17.0 | ≥70.0 | 0.40~1.00 | 2.25~2.75 | 5.00~9.00 | 0.70~1.20 |

| Co | Mn | Si | S | Cu | P |

| ≤1.00 | ≤0.35 | ≤0.35 | ≤0.010 | ≤0.50 | ≤0.015 |

| Mechanical properties | GH4145 plate offers excellent tensile strength, creep resistance, and fatigue strength, making it suitable for use in high-temperature environments. It has a melting range of 1360°C to 1430°C and can withstand temperatures up to 980°C without losing its strength. |