GH4169 Pipe

GH4169 Pipe is a high-performance nickel-based alloy, renowned for its exceptional strength and resistance to high temperatures and corrosion. It is widely used in a range of demanding applications where strength, durability, and reliability are paramount.

GH4169 Pipe offers superior strength and durability, making it an ideal choice for extreme applications. It has a high yield strength and tensile strength, which allows it to withstand high levels of stress and strain. This alloy also has excellent fatigue resistance, meaning it can withstand cyclic loading without failure, making it suitable for use in dynamic environments.

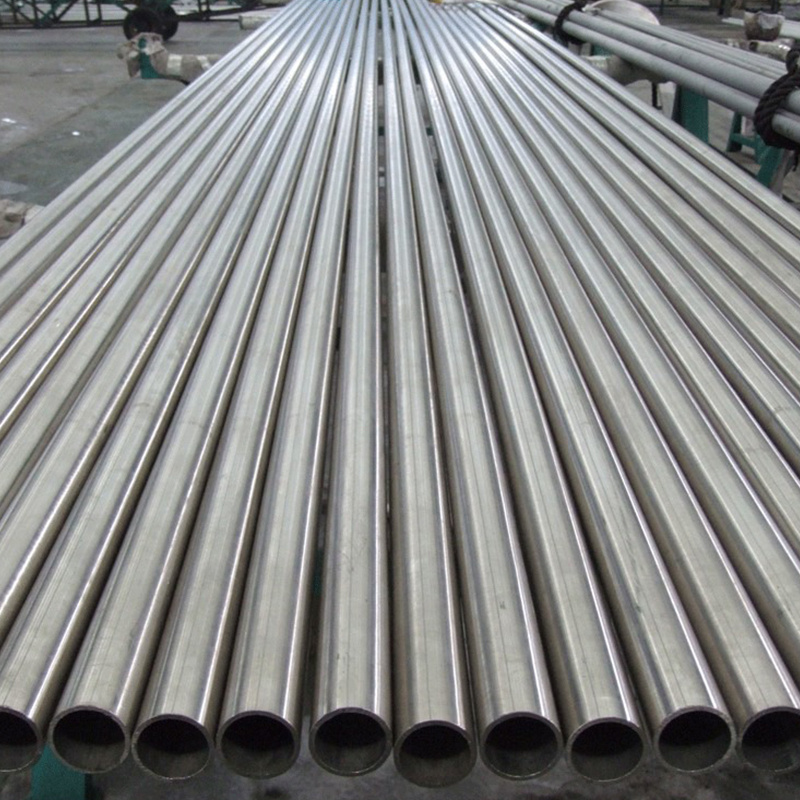

The exceptional corrosion resistance of GH4169 Pipe is another key advantage. It offers excellent resistance to acids, alkalis, and various other corrosive agents, making it well-suited for use in harsh chemical environments. This durability makes it a popular choice for oil and gas pipelines, chemical processing equipment, and other industrial applications where corrosion resistance is crucial.

GH4169 Pipe also excels in high-temperature environments. It has excellent creep strength and can withstand temperatures up to 980°C (1795°F) without significant loss of strength or ductility. This makes it an excellent choice for applications that require prolonged exposure to high temperatures, such as jet engine components and heat exchangers.

GH4169 Pipe is used in a wide range of applications where its exceptional strength, durability, and corrosion resistance are required. Some of the most common applications include:

Oil and gas pipelines: GH4169 Pipe is often used in oil and gas pipelines due to its exceptional corrosion resistance and high-temperature performance. It ensures the safe transportation of oil and gas over long distances.

Aircraft components: GH4169 Pipe is used in aircraft components that require high strength, fatigue resistance, and corrosion resistance. It is often used in landing gear, engine components, and other critical aircraft parts.

Industrial heat exchangers: GH4169 Pipe is used in industrial heat exchangers due to its high-temperature performance and corrosion resistance. It ensures efficient heat transfer and longevity in harsh industrial environments.

Chemical processing equipment: GH4169 Pipe is used in chemical processing equipment due to its exceptional corrosion resistance. It ensures the safe handling of corrosive chemicals and extends the lifespan of the equipment.

| Product Name: GH4169 Pipe |

| Chemical Composition |

| C | Cr | Ni | Co | Mo | Al | Ti | Fe |

| ≤0.08 | 17.0~21.0 | 50~55.0 | ≤1.0 | 2.80~3.30 | 0.30~0.70 | 0.75~1.15 | Balance |

| Nb | B | Mg | Mn | Si | P | S | Cu | Ca |

| - | ≤ | ≤ | ≤ | ≤ | ≤ | ≤ | ≤ | ≤ |

| 4.75~5.50 | 0.006 | 0.01 | 0.35 | 0.35 | 0.015 | 0.015 | 0.30 | 0.01 |

| Mechanical Properties | GH4169 pipe exhibits excellent tensile strength, creep strength, and fatigue resistance. Typical yield strength and tensile strength values are in excess of 1,000 MPa and 1,200 MPa, respectively. The material also displays good ductility and fracture toughness, making it suitable for a range of complex and demanding applications. |

| Thermal Properties | GH4169 pipe has excellent thermal stability, with a melting range of approximately 1260-1320°C. It has good thermal conductivity and a low coefficient of thermal expansion, which contributes to its reliability in high-temperature applications. |