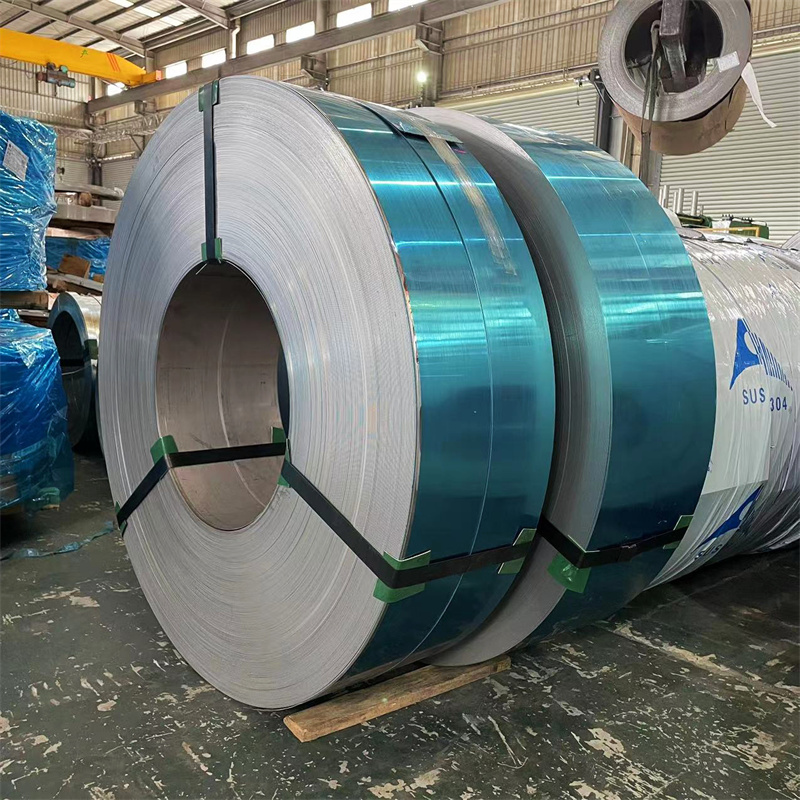

Hastelloy C-3 (HB3) Coil

Hastelloy C-3, also known as HB3, is a high-performance nickel-based alloy that offers exceptional resistance to a wide range of corrosive environments. This unique material is widely used in various industries where stringent corrosion resistance and high-temperature strength are essential. Hastelloy C-3 coil is specifically designed for demanding applications that require reliable and long-lasting performance.

Exceptional corrosion resistance: Hastelloy C-3 offers superior resistance to acids, alkalis, and various other corrosive substances, making it an ideal choice for severe chemical processing environments.

High-temperature strength: The alloy maintains its strength even at elevated temperatures, making it suitable for use in high-temperature applications.

Durable and reliable: Hastelloy C-3 coil has excellent mechanical properties, providing long-lasting performance with minimal maintenance requirements.

Easy to fabricate: The material is easy to cut, drill, weld, and fabricate, reducing the overall cost of production and installation.

Versatile application: Hastelloy C-3 coil can be used in various industries such as chemical processing, petroleum refining, mining, and pulp and paper manufacturing.

Hastelloy C-3 coil offers a unique combination of corrosion resistance, high-temperature strength, and ease of fabrication. It provides long-lasting performance and reliability in severe service conditions, making it an excellent choice for critical applications. Additionally, the material offers good weldability and can be easily joined using standard welding procedures. Hastelloy C-3 coil is also available in a wide range of sizes and shapes to meet specific application requirements.

The Hastelloy C-3 coil manufacturing process involves several key steps to ensure the highest quality material that meets specific performance requirements. The process typically includes:

Casting: The alloy is cast into ingots or billets using vacuum induction melting (VIM) or electro-slag remelting (ESR) processes. These processes ensure the purity and consistency of the material.

Hot Rolling: The cast ingots or billets are hot rolled into sheets or plates using precision rolling mills. This step controls the thickness and width of the material.

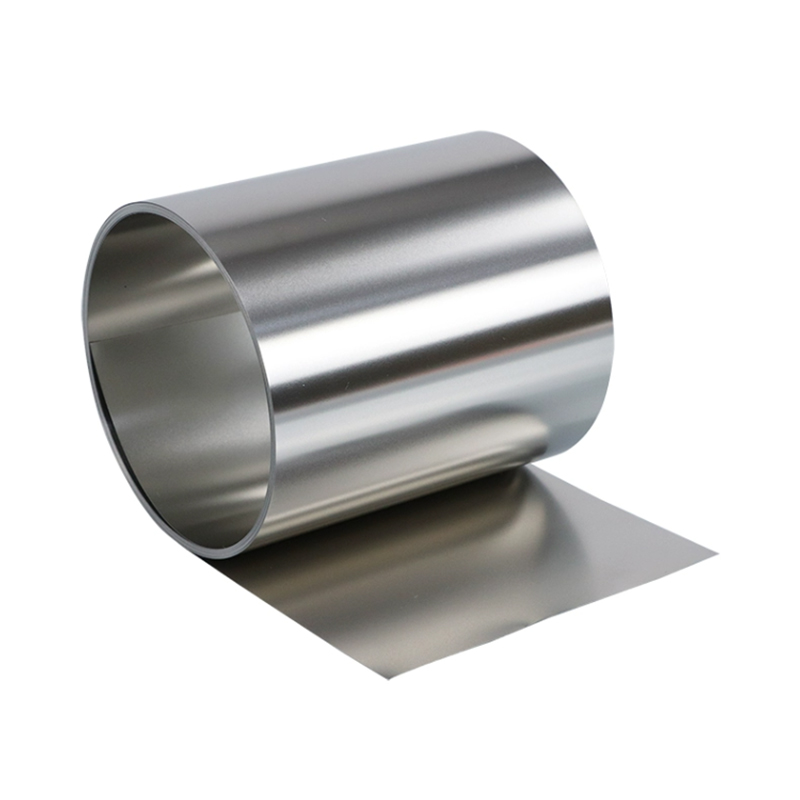

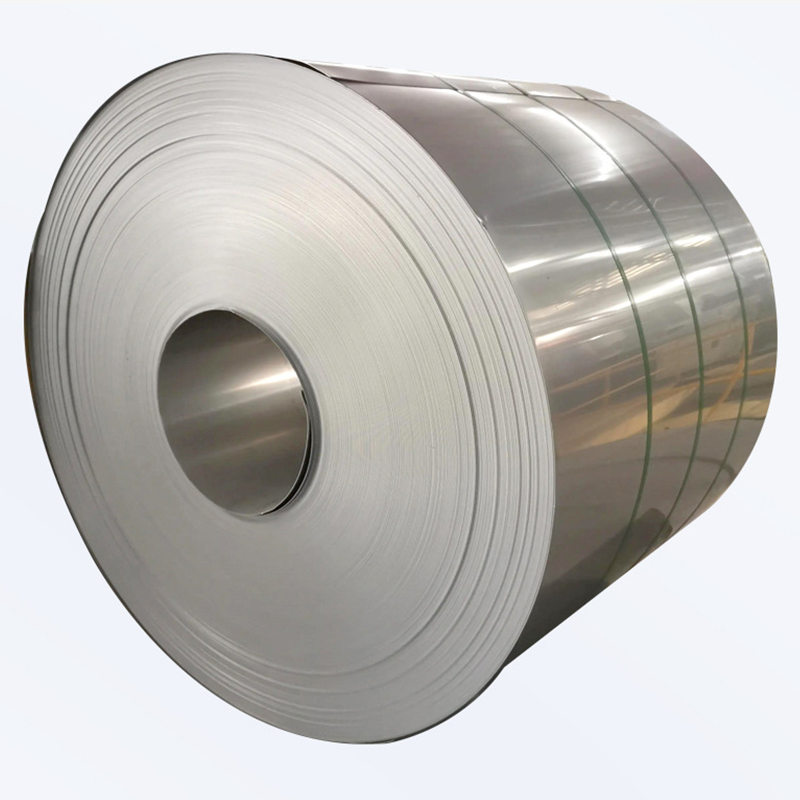

Coiling: The rolled sheets or plates are coiled into coils with tight tolerances to ensure consistent quality and dimensional accuracy.

Annealing: The coiled material undergoes annealing to remove any residual stress and improve its mechanical properties.

Surface Finishing: The coil surface is finished to remove any imperfections and provide a smooth finish for improved appearance and corrosion resistance.

Applications of Hastelloy C-3 (HB3) Coil

Hastelloy C-3 coil is widely used in various industries due to its exceptional corrosion resistance and high-temperature strength. Some common applications include:

Chemical Processing Equipment: Hastelloy C-3 coil is used in the manufacturing of chemical processing equipment such as reactors, tanks, piping systems, and valves that require exceptional corrosion resistance.

Petroleum Refining: In petroleum refining applications, Hastelloy C-3 coil is used in the manufacturing of piping systems, heat exchangers, and other process equipment that handle corrosive hydrocarbon streams.

Mining Operations: Hastelloy C-3 coil is employed in mining operations for the fabrication of equipment such as pumps, pipes, and conveyors that are exposed to aggressive acids and other corrosive substances.

Pulp and Paper Manufacturing: In pulp and paper manufacturing, Hastelloy C-3 coil is used in the production of pulp digesters, screens, filters, and other equipment that require resistance to corrosive chemicals and high temperatures.

| Parameter | Value |

| Alloy Composition | Nickel (Ni), Chromium (Cr), Molybdenum (Mo), Cobalt (Co), Tungsten (W), Iron (Fe) |

| Typical Composition | Ni: 70%, Cr: 16%, Mo: 8%, Co: 2%, W: 2%, Fe: 2% |

| Melting Range | 1260°C - 1350°C |

| Mechanical Properties | Yield Strength: ≥ 550 MPa, Tensile Strength: ≥ 700 MPa, Elongation: ≥ 30% |

| Thermal Stability | Heat Resistance up to 1000°C |

| Resistance to Corrosion | Excellent resistance to acids, alkalis, halogens, oxidizing and reducing agents. Also highly resistant to caustic solutions and seawater. |

| Application Fields | Chemical processing, Petroleum refining, Pharmaceutical industry, Seawater desalination, Wastewater treatment, Automotive exhaust systems, etc. |