Hastelloy C-3 (HB3) Rod

In modern industry, especially in chemical processing, offshore engineering and petroleum refining, there is a growing demand for materials that can maintain stable performance in extreme environments. Hastelloy C-3 (HB3) Rod, as a corrosion resistant alloy material, has shown its unique advantages and application value in these fields.

The unique properties of Hastelloy C-3 (HB3) Rod make it suitable for a variety of challenging environments. It offers excellent resistance to acids, alkalis, and other corrosive substances, making it an ideal choice for chemical processing, pollution control, and other industrial applications where exposure to corrosive media is unavoidable.

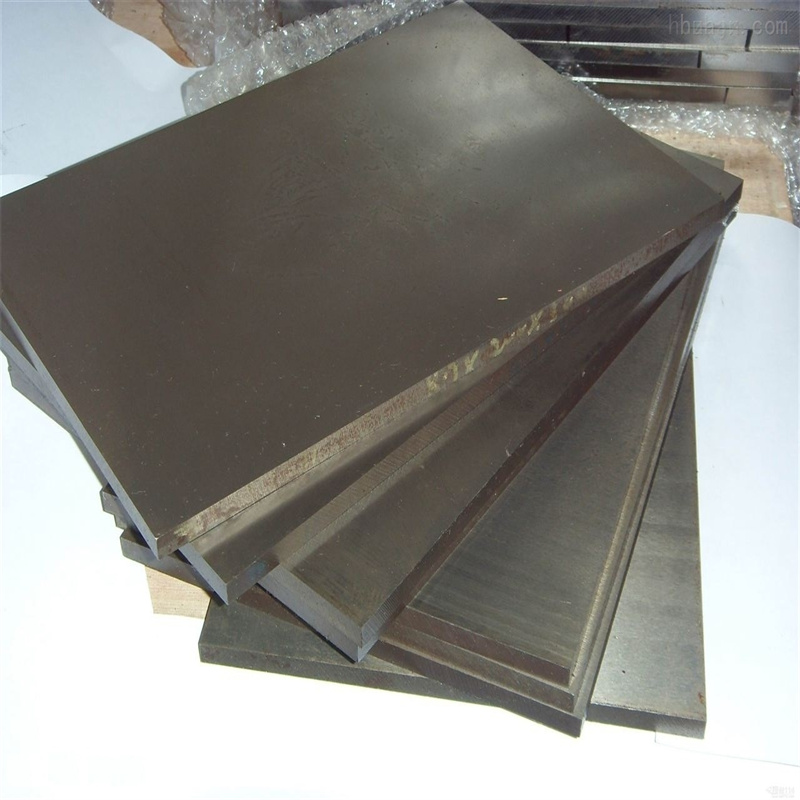

In addition to its corrosion resistance, Hastelloy C-3 (HB3) Rod also exhibits excellent mechanical properties. It has high tensile strength, yield strength, and fatigue resistance, making it suitable for use in dynamic applications where components are constantly exposed to stress and strain. This alloy is particularly well-suited for use in the manufacturing of pressure vessels, reactors, and other pressure-containing components.

Another key feature of Hastelloy C-3 (HB3) Rod is its excellent thermal stability. It can withstand high temperatures without losing its mechanical properties or corrosion resistance. This makes it an excellent choice for use in applications that require exposure to high temperatures, such as heat exchangers, furnaces, and other high-temperature equipment.

Furthermore, Hastelloy C-3 (HB3) Rod is easy to fabricate, making it well-suited for a range of manufacturing processes. It can be cut, welded, machined, and bent into a variety of shapes and sizes with relative ease, making it an attractive material for fabricators and manufacturers alike.

In conclusion, Hastelloy C-3 (HB3) Rod offers a unique combination of corrosion resistance, mechanical strength, thermal stability, and ease of fabrication. Its adaptability and reliability make it a go-to material for a wide range of industrial applications that demand exceptional performance under challenging conditions.

| Product Name: Hastelloy C-3 (HB3) Rod |

| Parameter | Value |

| Alloy Composition | Nickel (Ni), Chromium (Cr), Molybdenum (Mo), Cobalt (Co), Tungsten (W), Iron (Fe) |

| Typical Composition | Ni: 70%, Cr: 16%, Mo: 8%, Co: 2%, W: 2%, Fe: 2% |

| Melting Range | 1260°C - 1350°C |

| Mechanical Properties | Yield Strength: ≥ 550 MPa, Tensile Strength: ≥ 700 MPa, Elongation: ≥ 30% |

| Thermal Stability | Heat Resistance up to 1000°C |

| Resistance to Corrosion | Excellent resistance to acids, alkalis, halogens, oxidizing and reducing agents. Also highly resistant to caustic solutions and seawater. |

| Application Fields | Chemical processing, Petroleum refining, Pharmaceutical industry, Seawater desalination, Wastewater treatment, Automotive exhaust systems, etc. |