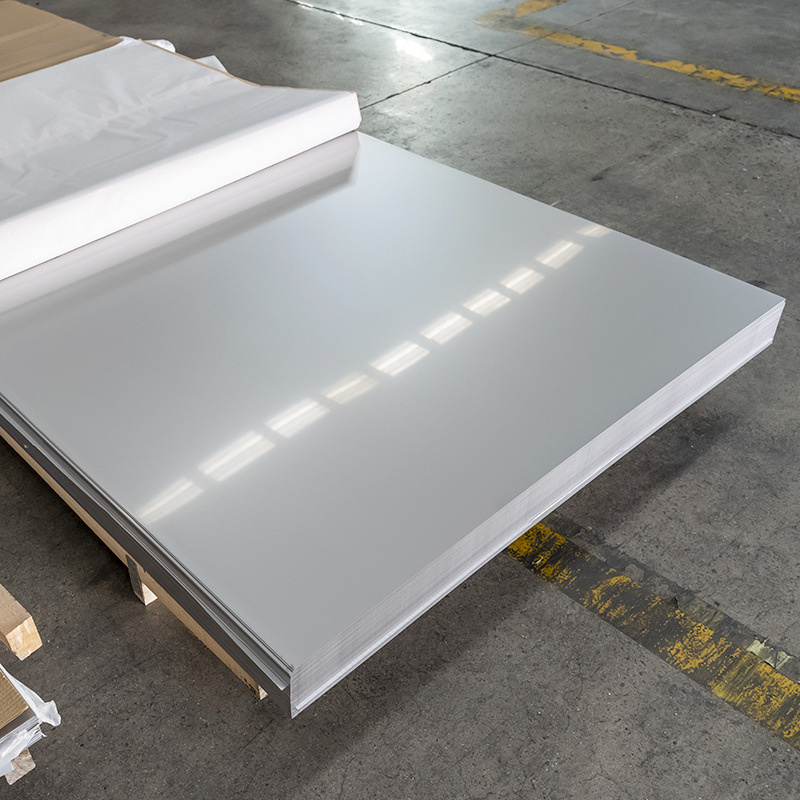

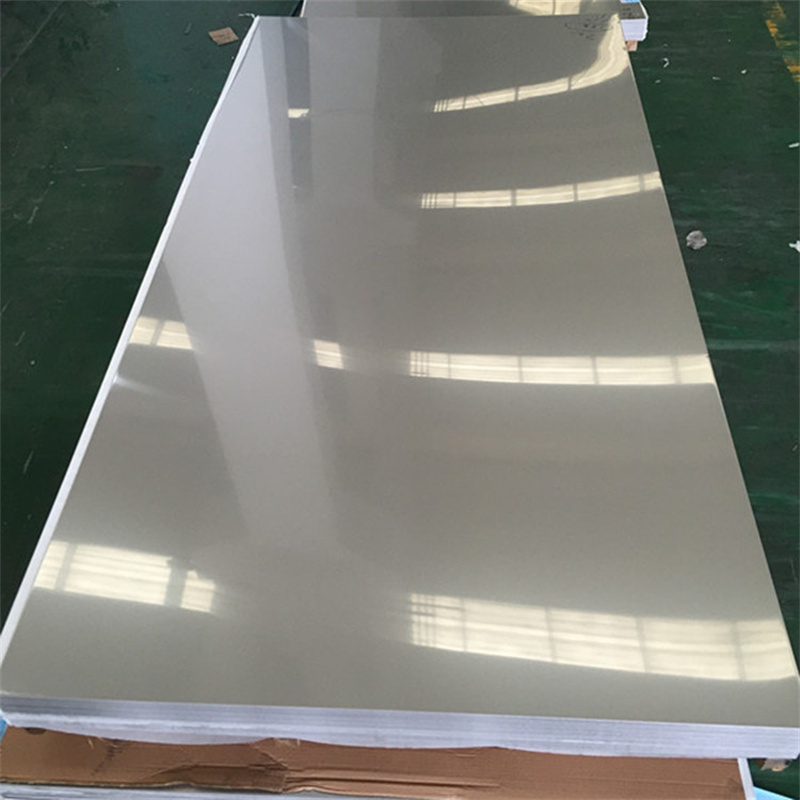

Hastelloy C-3 (HB3) Sheet

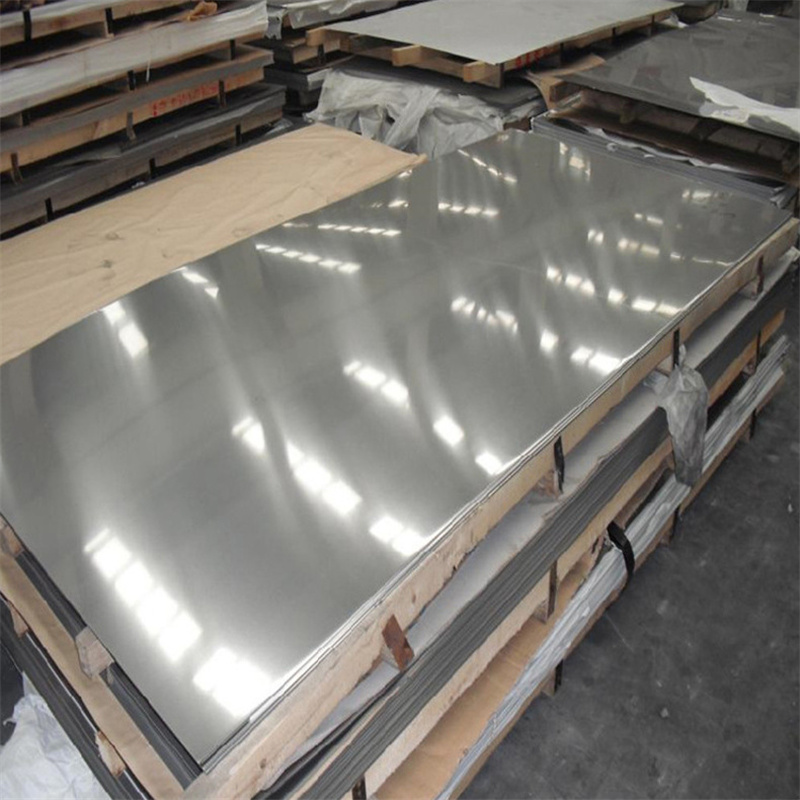

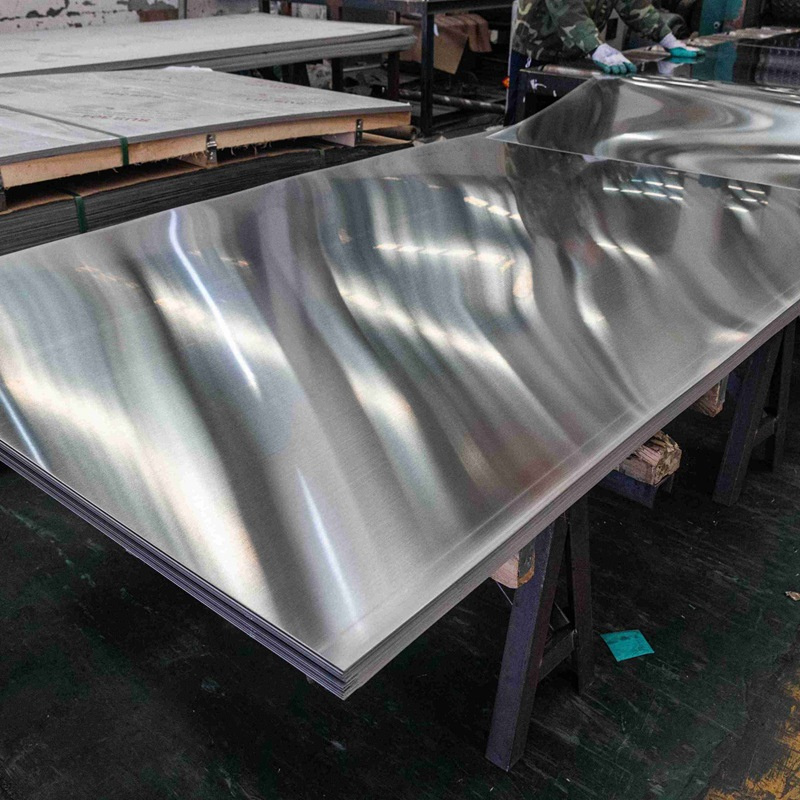

Hastelloy C-3 (HB3) sheet is a high-performance nickel-based alloy that offers exceptional resistance to corrosion and high-temperature environments. It is characterized by its excellent mechanical properties, making it suitable for a range of demanding applications.

Hastelloy C-3 (HB3) sheet offers the following key properties:

1.High corrosion resistance: Hastelloy C-3 (HB3) has excellent resistance to acids, alkalis, and oxidizing agents. It is also highly resistant to crevice corrosion and stress corrosion cracking, making it suitable for use in severe corrosive environments.

2.High temperature strength: Hastelloy C-3 (HB3) sheet maintains its mechanical properties at elevated temperatures, making it suitable for use in high-temperature applications. It has good creep resistance at elevated temperatures, ensuring long-term stability.

3.Good weldability: Hastelloy C-3 (HB3) sheet can be easily welded using standard welding techniques. It also has good post-weld corrosion resistance, making it suitable for fabrication and repair work.

4.Good mechanical properties: Hastelloy C-3 (HB3) sheet exhibits good tensile strength, ductility, and impact strength, ensuring robust performance in various applications.

Hastelloy C-3 (HB3) sheet is used in a wide range of applications, including:

1.Chemical processing: Hastelloy C-3 (HB3) sheet is used in the chemical processing industry, where it is exposed to corrosive chemicals and high temperatures. It is commonly used in reactor vessels, piping, and storage tanks.

2.Aerospace and aircraft components: Hastelloy C-3 (HB3) sheet is used in the aerospace industry due to its high-temperature strength and corrosion resistance. It is commonly used in aircraft engines, fuel systems, and other critical components.

3.Power generation: Hastelloy C-3 (HB3) sheet is used in power generation plants, where it is exposed to high temperatures and corrosive environments. It is commonly used in boiler components, heat exchangers, and other critical equipment.

4.Oil and gas industry: Hastelloy C-3 (HB3) sheet is used in the oil and gas industry due to its resistance to acids and other corrosive substances found in drilling fluids and produced water. It is commonly used in pipelines, valves, and other components in oil and gas production facilities.

In summary, Hastelloy C-3 (HB3) sheet offers exceptional resistance to corrosion and high temperatures, making it a highly versatile material for various demanding applications. Its good mechanical properties and ease of welding make it an excellent choice for fabricating components that require long-term durability and reliability.

| Product Name: Hastelloy C-3 (HB3) Sheet |

| Parameter | Value |

| Alloy Composition | Nickel (Ni), Chromium (Cr), Molybdenum (Mo), Cobalt (Co), Tungsten (W), Iron (Fe) |

| Typical Composition | Ni: 70%, Cr: 16%, Mo: 8%, Co: 2%, W: 2%, Fe: 2% |

| Melting Range | 1260°C - 1350°C |

| Mechanical Properties | Yield Strength: ≥ 550 MPa, Tensile Strength: ≥ 700 MPa, Elongation: ≥ 30% |

| Thermal Stability | Heat Resistance up to 1000°C |

| Resistance to Corrosion | Excellent resistance to acids, alkalis, halogens, oxidizing and reducing agents. Also highly resistant to caustic solutions and seawater. |

| Application Fields | Chemical processing, Petroleum refining, Pharmaceutical industry, Seawater desalination, Wastewater treatment, Automotive exhaust systems, etc. |