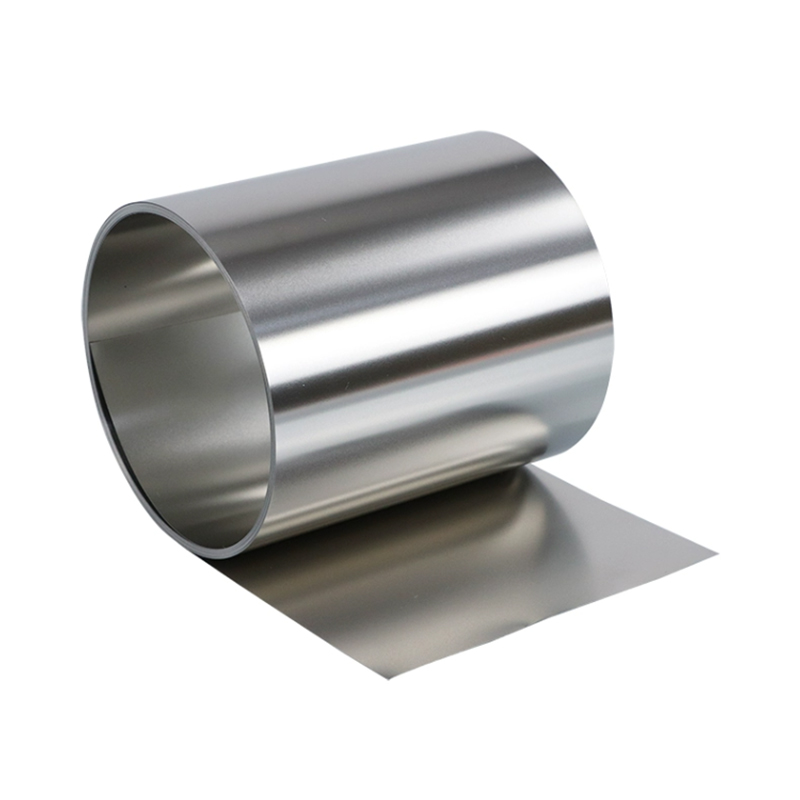

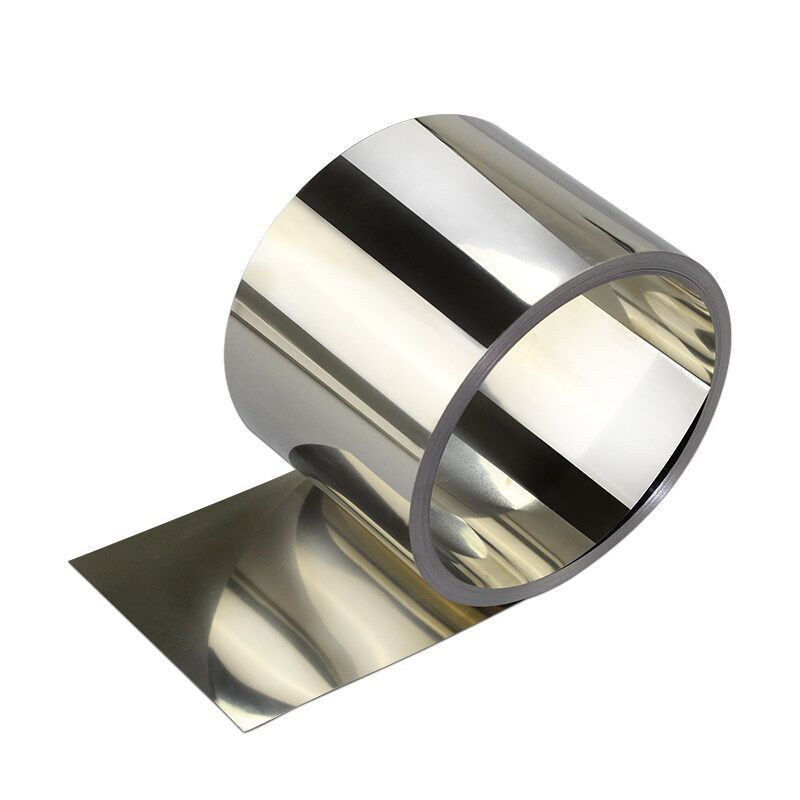

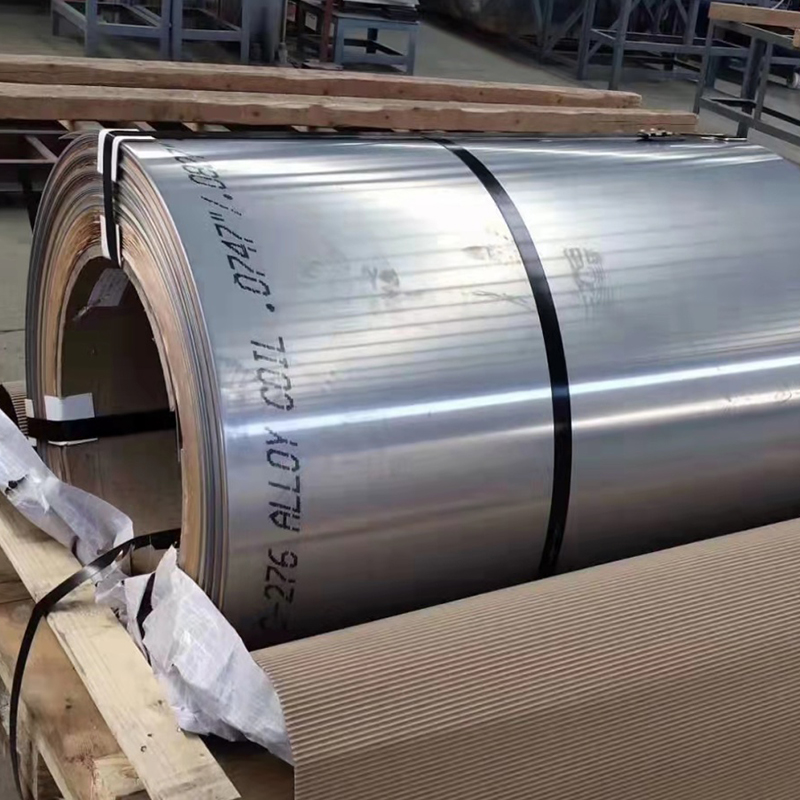

Hastelloy C22 Coil

Hastelloy C22 coil is a high-performance nickel-chromium-molybdenum alloy, renowned for its exceptional resistance to a wide range of corrosive environments. With its unique combination of properties, Hastelloy C22 coil offers a dependable solution for demanding applications in various industries.

In terms of corrosion resistance, Hastelloy C22 coil excels in aggressive environments that contain acids, bases, and oxidizing solutions. It effectively withstands chloride-ion stress corrosion cracking, making it an excellent choice for use in seawater and other chloride-containing environments. Additionally, Hastelloy C22 coil offers good resistance to high-temperature oxidation, making it suitable for use in high-temperature applications.

Hastelloy C22 coil also exhibits excellent mechanical properties, including high strength and ductility. It has good forming and welding characteristics, making it easy to fabricate into various shapes and sizes. The alloy is also characterized by its good fatigue strength and cracking resistance, which makes it suitable for use in cyclic loading applications.

Due to its exceptional corrosion resistance and mechanical properties, Hastelloy C22 coil finds a wide range of applications across various industries. Some of the common applications include:

Oil and Gas Industry: Hastelloy C22 coil is widely used in the oil and gas industry for the offshore and onshore drilling and production equipment. It provides exceptional corrosion resistance in sour-gas environments and is suitable for use in pipelines, valves, and other critical components.

Chemical Processing: Hastelloy C22 coil is ideal for use in chemical processing plants, where it encounters corrosive chemicals and high-temperature environments. It is commonly used in reactors, tanks, piping systems, and other process equipment.

Power Generation: Hastelloy C22 coil is used in power generation facilities, especially those that burn coal or use nuclear energy. It provides exceptional corrosion resistance in the boiler systems, condensers, and other critical components of the power plants.

Aerospace and Aviation: Hastelloy C22 coil is used in the aerospace and aviation industry due to its high-temperature oxidation resistance and excellent fatigue properties. It is commonly used in aircraft engines, fuel systems, and other critical components.

Infrastructure: Hastelloy C22 coil is also used in infrastructure projects such as bridges, tunnels, and buildings. It provides exceptional corrosion resistance in harsh environments and is suitable for use in various structural components.

In summary, Hastelloy C22 coil offers a dependable solution for a wide range of corrosion-resistant applications. With its exceptional resistance to acids, bases, and oxidizing solutions, Hastelloy C22 coil provides long-lasting performance in various industries, making it a valuable investment for your corrosion-resistant needs.

| Product Name: Hastelloy C22 Coil |

| Ni | Cr | Fe | W | Mo | Co | C | Si |

| Balance | 22.0-24.0 | ≤2.0 | 3.0-5.0 | 2.0-3.0 | ≤1.0 | ≤0.08 | ≤0.50 |

| Mn | P | S | Ti | Al | Zr | Sn | B |

| ≤1.00 | ≤0.045 | ≤0.030 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.15 | ≤0.015 |

| Mechanical Properties |

| Hastelloy C22 coil exhibits high tensile strength, with a minimum yield strength of 210 ksi. It also has good ductility and impact toughness, making it suitable for various forming operations. The material has a Brinell hardness of approximately 180 to 210 HB. |

| Corrosion Resistance |

| Hastelloy C22 coil offers excellent resistance to a wide range of corrosive environments, including acids, alkalis, and oxidizing solutions. It is highly resistant to pitting, crevice corrosion, and stress corrosion cracking. The material's exceptional corrosion resistance is attributed to its unique composition, which includes nickel, chromium, and molybdenum. |