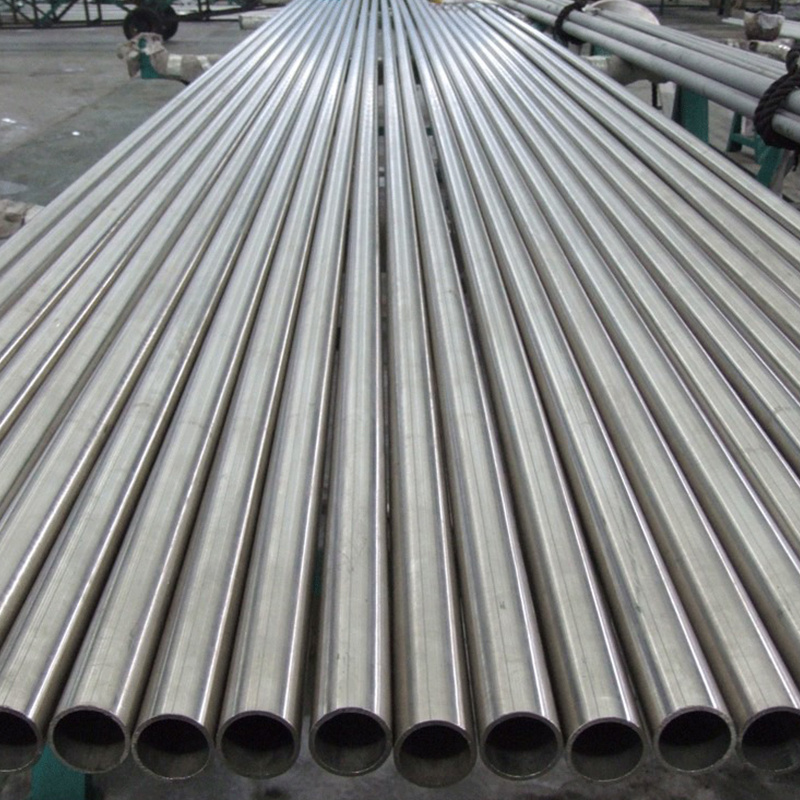

Hastelloy C22 pipe

Resistance to acids: Hastelloy C22 pipe is highly resistant to acids, including sulfuric, nitric, and phosphoric acids, as well as mixtures containing these acids. This makes it an excellent choice for use in processes involving these acids, such as pickling, cleaning, and other chemical processing operations.

Resistance to corrosion: Hastelloy C22 pipe offers excellent resistance to corrosion in chloride-containing environments, making it suitable for use in seawater piping systems, pulp and paper processing, and other industrial applications where chloride ions are present.

High temperature resistance: Hastelloy C22 pipe can withstand temperatures up to 1000°F (538°C), making it suitable for use in high-temperature applications such as furnaces, heat exchangers, and reactors.

Hastelloy C22 pipe exhibits good mechanical properties, including high strength and ductility. It has good fatigue resistance and is easy to fabricate, making it suitable for a variety of industrial applications where mechanical integrity is crucial.

Hastelloy C22 pipe is used in a wide range of industries, including chemical processing, oil and gas, pulp and paper, and other industrial applications where exceptional corrosion resistance is required. It is commonly used in piping systems, reactors, heat exchangers, and other pressure containing components.

Conclusion

Hastelloy C22 pipe offers a unique combination of corrosion resistance, mechanical properties, and temperature tolerance that make it an excellent choice for use in severe industrial environments. Its resistance to acids and chlorides, as well as its high-temperature capabilities, make it suitable for a wide range of applications across multiple industries. With its reliable performance and long service life, Hastelloy C22 pipe is a valuable asset for ensuring the durability and reliability of critical industrial processes.

| Product Name: Hastelloy C22 pipe |

| Ni | Cr | Fe | W | Mo | Co | C | Si |

| Balance | 22.0-24.0 | ≤2.0 | 3.0-5.0 | 2.0-3.0 | ≤1.0 | ≤0.08 | ≤0.50 |

| Mn | P | S | Ti | Al | Zr | Sn | B |

| ≤1.00 | ≤0.045 | ≤0.030 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.15 | ≤0.015 |

| Tensile performance | Hastelloy C22 has a high tensile strength, typically between 690-965 MPa. It also has good elongation, usually between 30-50%. The tensile properties of this alloy make it suitable for components that withstand high stress and bending. |

| Yield strength | Hastelloy C22 has a high yield strength, typically between 345-515 MPa. This means that the alloy is less prone to permanent deformation when subjected to stress. |

| Hardness | Hastelloy C22 can achieve a hardness range of HRB 90-100 through heat treatment. The increase in hardness helps to improve wear resistance and corrosion resistance. |

| Fatigue strength | Hastelloy C22 has good fatigue strength, which means it can withstand repeated cyclic loading without fatigue fracture. This performance makes it suitable for components that need to withstand periodic loads, such as turbines and pumps. |

| Impact toughness | Hastelloy C22 has a high impact toughness, typically between 100-150 J/cm ² Between. This indicates that the alloy has good resistance to impact and vibration, and is less prone to brittle fracture. |