Hastelloy C22 Plates

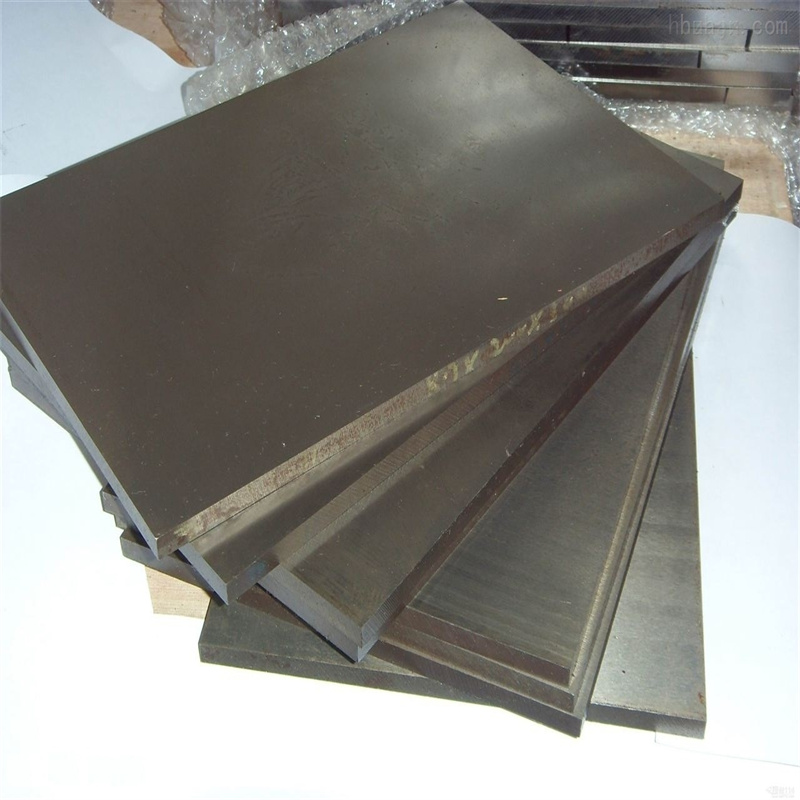

Hastelloy C22 plates are a part of the Hastelloy family, renowned for their exceptional corrosion resistance and high performance in challenging environments. Hastelloy C22, in particular, is composed of nickel, chromium, molybdenum, and tungsten, offering outstanding resistance to a wide range of corrosive media.

Chemical Processing: Hastelloy C22 plates are widely used in the chemical industry for constructing chemical reactors, vessels, and other equipment handling corrosive substances.

Petrochemical Industry: Common applications include reactors, distillation columns, and heat exchangers in petrochemical processes.

Pollution Control: Hastelloy C22 plates are employed in pollution control equipment, such as scrubbers and exhaust systems, due to their resistance to acidic gases.

Pharmaceutical Manufacturing: The alloy is suitable for pharmaceutical applications where corrosion-resistant materials are essential.

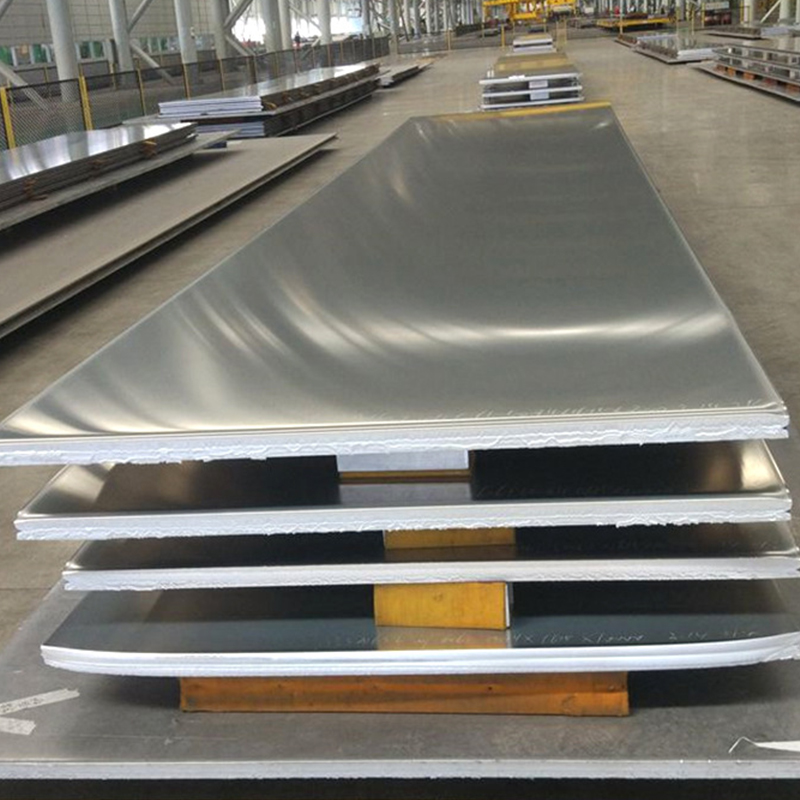

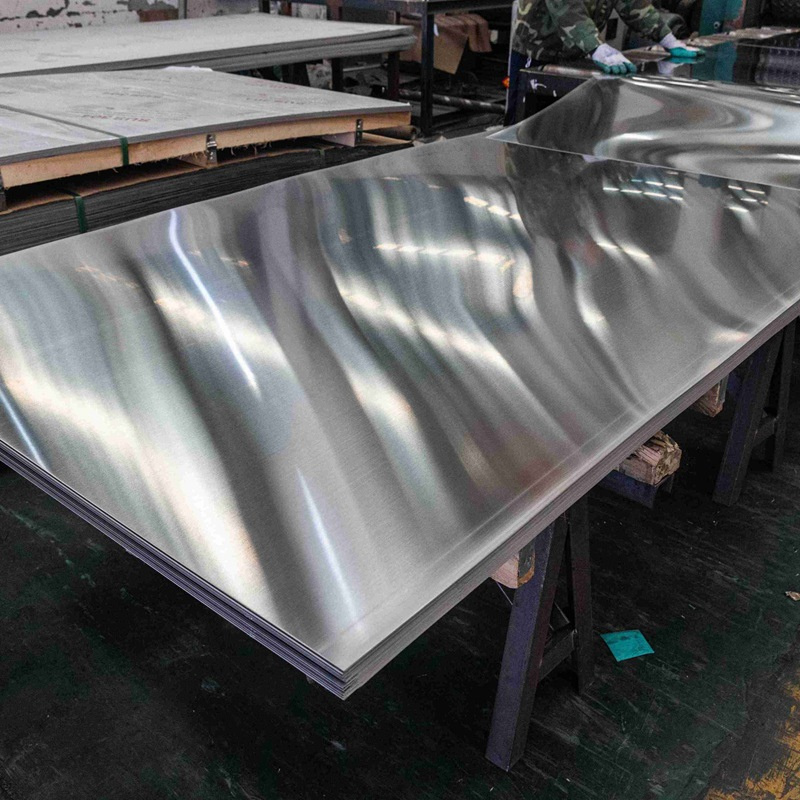

Hastelloy C22 plates are available in various dimensions and thicknesses, catering to the diverse needs of industries. They can be further processed for specific applications.

Hastelloy C22 plates conform to international standards such as ASTM and ASME, ensuring consistent quality and performance.

Ongoing research aims to optimize the composition and properties of Hastelloy C22 plates to meet evolving industry requirements and enhance overall performance.

In conclusion, Hastelloy C22 plates are crucial components in industries requiring corrosion-resistant materials, offering reliability and durability in challenging environments. Their versatility and high-performance characteristics make them a preferred choice for various applications across different sectors.

| Product Name: Hastelloy C22 Plates |

| Chemical Composition |

| Ni | Cr | Fe | W | Mo | Co | C | Si |

| Balance | 22.0-24.0 | ≤2.0 | 3.0-5.0 | 2.0-3.0 | ≤1.0 | ≤0.08 | ≤0.50 |

| Mn | P | S | Ti | Al | Zr | Sn | B |

| ≤1.00 | ≤0.045 | ≤0.030 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.15 | ≤0.015 |

| Corrosion Resistance | Hastelloy C22 plates exhibit superior resistance to oxidizing and reducing acids, as well as pitting, crevice corrosion, and stress corrosion cracking, making them suitable for aggressive chemical environments. |

| Versatility | These plates are well-suited for applications in both oxidizing and reducing conditions, providing versatility across various industries. |

| High Temperature Performance | Hastelloy C22 maintains its mechanical properties at elevated temperatures, making it ideal for applications such as chemical processing and high-temperature reactors. |

| Weldability | Hastelloy C22 plates are easily weldable, allowing for the fabrication of complex structures and components. |