Hastelloy C22 Rod

Hastelloy C22 Rod is a high-performance nickel-based alloy, renowned for its exceptional resistance to a wide range of corrosive environments. It offers superior strength and ductility, making it an ideal material for a variety of critical applications in extreme environments.

The unique combination of properties in Hastelloy C22 Rod is achieved through a precise alloy composition. It contains nickel, iron, cobalt, and a range of alloying elements, including chromium, molybdenum, tungsten, and titanium. These elements contribute to the alloy's exceptional resistance to acids, alkalis, and other corrosive substances.

Hastelloy C22 Rod offers excellent resistance to chloride-ion stress corrosion cracking, making it an excellent choice for use in seawater environments. It also exhibits excellent resistance to oxidizing agents and is highly resistant to acids, including sulfuric acid and nitric acid. This makes it well-suited for use in a variety of chemical processing applications.

In addition to its exceptional corrosion resistance, Hastelloy C22 Rod offers excellent mechanical properties. It has high tensile strength and fatigue strength, making it suitable for use in applications where high loads and repeated stress are encountered. It also has good forming and welding characteristics, facilitating ease of fabrication and repair.

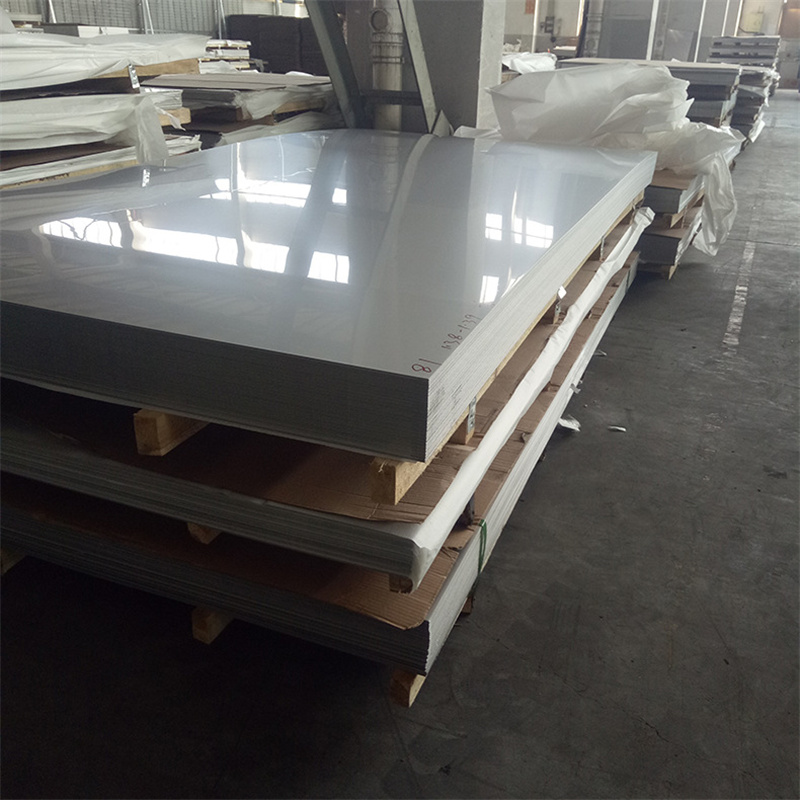

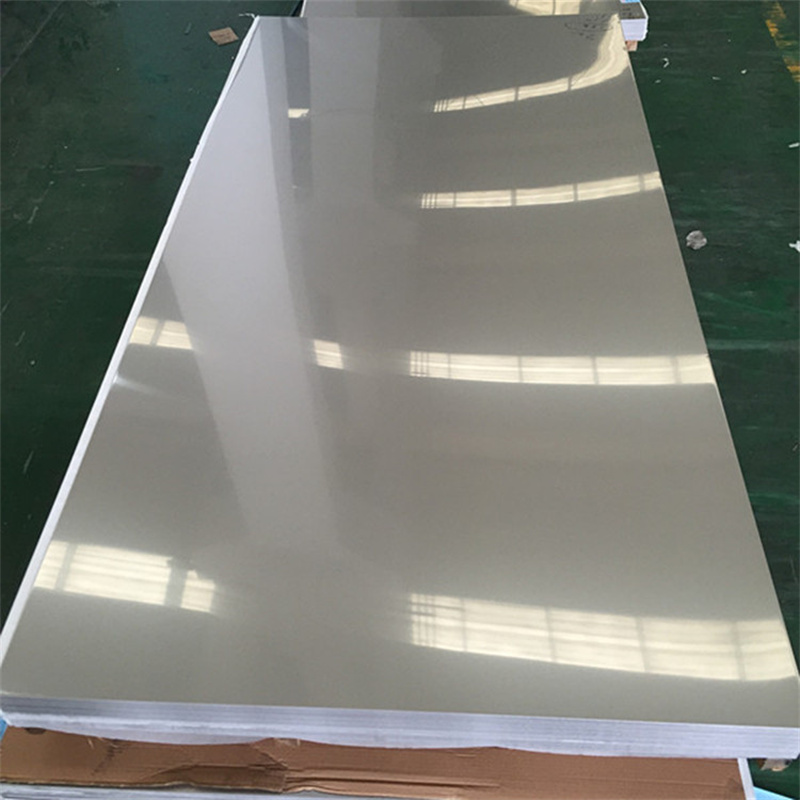

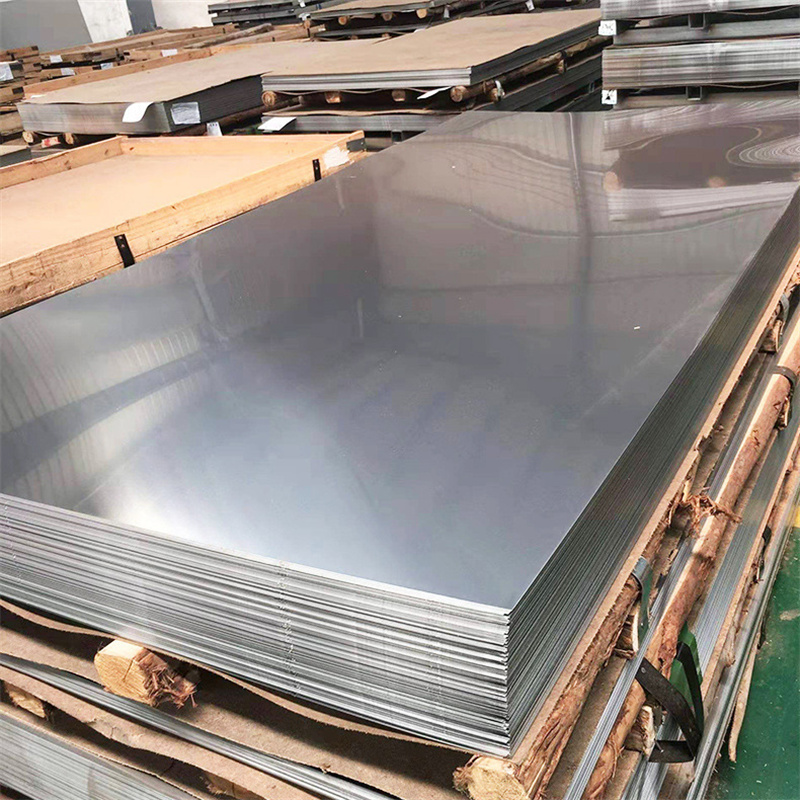

Hastelloy C22 Rod is available in various forms, including rods, tubes, sheets, and more. It can be supplied in a range of sizes and dimensions to meet specific application requirements. It is commonly supplied in annealed and stress-relieved conditions, ensuring optimal material properties for the desired application.

Due to its exceptional corrosion resistance and mechanical properties, Hastelloy C22 Rod is widely used in a range of industries. It is commonly employed in the chemical processing industry, where it is used in the handling and transportation of corrosive chemicals. It is also used in the petroleum industry, particularly in oil and gas production, refining, and pipelines. Hastelloy C22 Rod is also utilized in the power generation industry, as well as in the pulp and paper industry for paper machine components that are exposed to corrosive environments.

In conclusion, Hastelloy C22 Rod offers an excellent combination of corrosion resistance, mechanical properties, and versatility. Its unique alloy composition provides exceptional resistance to a wide range of corrosive environments, making it well-suited for use in various demanding applications across multiple industries. With its exceptional performance and durability, Hastelloy C22 Rod is a valuable asset for meeting the challenges of corrosion in extreme environments.

| Product Name: Hastelloy C22 Rod |

| Ni | Cr | Fe | W | Mo | Co | C | Si |

| Balance | 22.0-24.0 | ≤2.0 | 3.0-5.0 | 2.0-3.0 | ≤1.0 | ≤0.08 | ≤0.50 |

| Mn | P | S | Ti | Al | Zr | Sn | B |

| ≤1.00 | ≤0.045 | ≤0.030 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.15 | ≤0.015 |

| The specific mechanical properties of Hastelloy C22 depend on the material's thickness and heat treatment. The modulus of elasticity ranges from 205 to 215 GPa, depending on the annealing temperature used during processing. The alloy's tensile strength is typically between 690 and 910 MPa, while the yield strength is between 450 and 690 MPa. The elongation at fracture ranges from 35 to 50%, and the reduction in area is typically between 40 and 65%. |