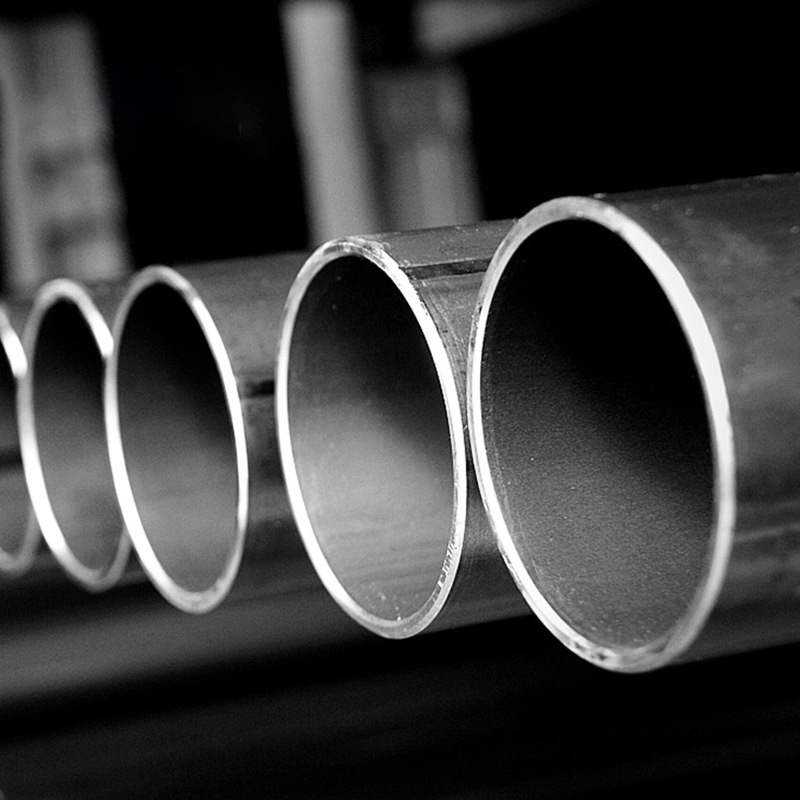

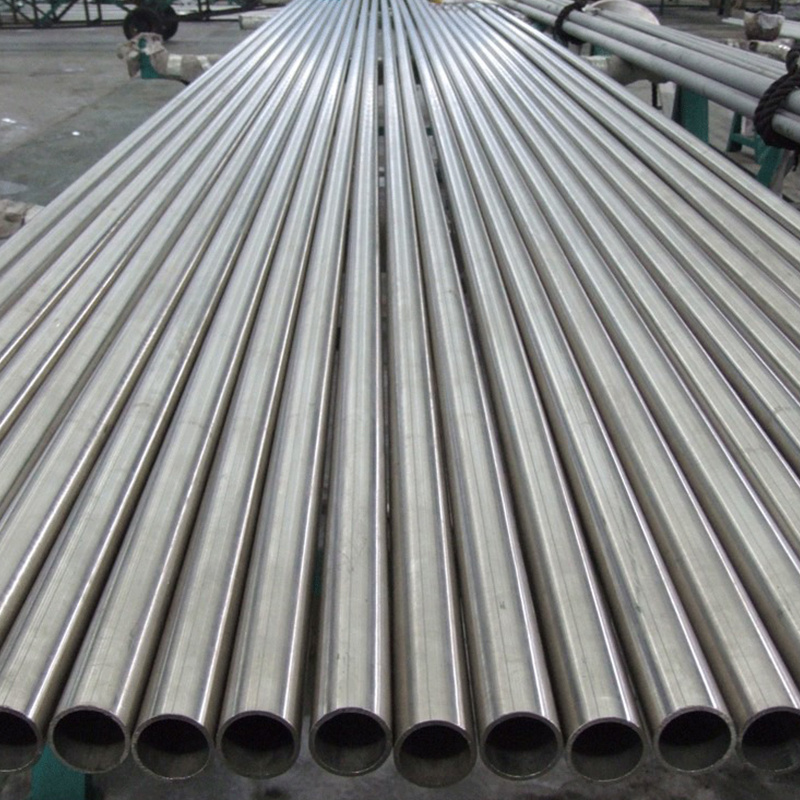

Hastelloy C276 Pipe

Hastelloy C276 pipe is a nickel-based alloy that offers exceptional resistance to a wide range of corrosive environments. It is a highly versatile material, finding applications in industries where extreme corrosion resistance is crucial, such as chemical processing, nuclear power generation, and oil and gas exploration.

The key attribute that sets Hastelloy C276 pipe apart is its exceptional resistance to acids, alkalis, and a variety of corrosive gases. This makes it an excellent choice for use in environments where other materials would rapidly corrode or fail. The material's corrosion resistance is further enhanced by its resistance to stress corrosion cracking, making it an ideal choice for high-temperature and high-pressure applications.

In addition to its corrosion resistance, Hastelloy C276 pipe also offers good mechanical properties. It has excellent tensile strength and ductility, making it suitable for use in a range of manufacturing processes and under demanding operating conditions. The material also has good weldability, allowing it to be easily joined to other components during fabrication.

Another advantage of Hastelloy C276 pipe is its excellent resistance to crevice corrosion. This phenomenon occurs when the metal is subjected to tensile stress in a corrosive environment, leading to localized corrosion in crevices or narrow gaps. The material's resistance to crevice corrosion makes it particularly suitable for use in applications where crevices are unavoidable, such as in piping systems or heat exchangers.

Hastelloy C276 pipe is available in a range of forms and sizes, including seamless and welded pipes, as well as fittings and flanges. It can be supplied in both annealed and cold-worked conditions, allowing for further processing and optimization of mechanical properties.

Overall, Hastelloy C276 pipe is an excellent choice for applications that require exceptional corrosion resistance in extreme environments. Its combination of mechanical strength, corrosion resistance, and good weldability makes it a highly versatile material for a wide range of industrial applications.

| Product Name: Hastelloy C276 Pipe |

| Chemical Composition |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00– 7.00 | 15.00 – 17.00 | 0.04 max |

| Mechanical Properties | Hastelloy C276 pipe exhibits excellent tensile strength, yield strength, and impact resistance. It has a tensile strength ranging from 690 to 965 MPa and a yield strength of 290 MPa. The alloy's impact resistance is further enhanced by its retained ductility, even at cryogenic temperatures. |

| Corrosion Resistance | Hastelloy C276 pipe is highly resistant to acids, alkalis, and a wide range of corrosive environments. It is commonly used in severe chemical processing environments where other materials would rapidly corrode. The corrosion resistance of Hastelloy C276 pipe is further enhanced by its passivation characteristics, which form a protective oxide layer on the surface of the material. |

| Temperature Resistance | Hastelloy C276 pipe can withstand temperatures ranging from cryogenic (-196°C) to high-temperature (up to 1000°C) environments. It maintains its mechanical properties and corrosion resistance at elevated temperatures, making it suitable for use in severe industrial processes involving high-temperature corrosive environments. |

| Fabrication and Welding | Hastelloy C276 pipe can be fabricated using conventional techniques such as cutting, bending, and threading. However, special care should be taken during welding to prevent alloying element loss or excessive heat input, which can affect the corrosion resistance of the material. Proper pre- and post-weld heat treatment is essential to ensure the integrity of the Hastelloy C276 pipe joint. |