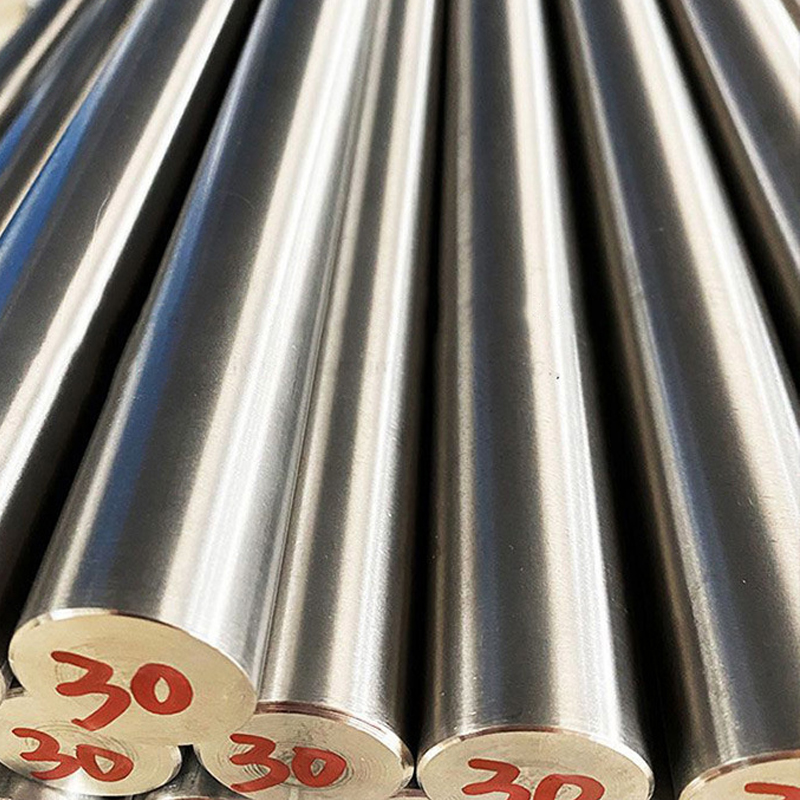

Hastelloy C276 Rod

The unique properties of Hastelloy C276 Rod are derived from its chemical composition, which includes chromium, molybdenum, tungsten, iron, and cobalt, among other alloying elements. The combination of these elements results in a material that is highly resistant to acids, alkalis, and a wide range of other corrosive substances. It can withstand extreme environments where other alloys would quickly corrode or fail.

In addition to its corrosion resistance, Hastelloy C276 Rod offers excellent mechanical properties. It has high tensile strength and ductility, making it suitable for both forming and machining operations. The material also exhibits good fatigue resistance, ensuring longevity in cyclic loading applications.

The versatility of Hastelloy C276 Rod extends beyond its corrosion resistance and mechanical properties. It can be used in a wide range of industries, including chemical processing, power generation, oil and gas exploration, and pulp and paper manufacturing. It is often used in situations where traditional materials would quickly corrode or fail, making it a cost-effective solution for replacing more expensive and less durable materials.

Hastelloy C276 Rod is available in various forms, including rods, tubes, sheets, and more. It can be supplied in both annealed and cold-worked conditions, allowing for further processing flexibility. The material is also weldable, making it easy to integrate into existing structures or create new components.

When selecting Hastelloy C276 Rod for your application, it is important to consider the specific requirements of the project. The material’s high cost compared to some other alloys can be offset by its exceptional performance and longevity. It is essential to work with a trusted supplier who can provide quality material and ensure that it is processed and fabricated according to industry standards.

In conclusion, Hastelloy C276 Rod offers an outstanding combination of corrosion resistance, mechanical strength, and versatility that makes it a valuable metalworking companion. Its adaptability across various industries and ability to withstand extreme environments make it a go-to material for demanding applications where durability and performance are paramount. With the proper selection and processing, Hastelloy C276 Rod can help achieve cost savings through extended component lifetimes while ensuring the reliability and durability required for critical operations.

| Product Name: Hastelloy C276 Rod |

| Chemical Compatibility |

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00– 7.00 | 15.00 – 17.00 | 0.04 max |

| Mechanical Strength |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |