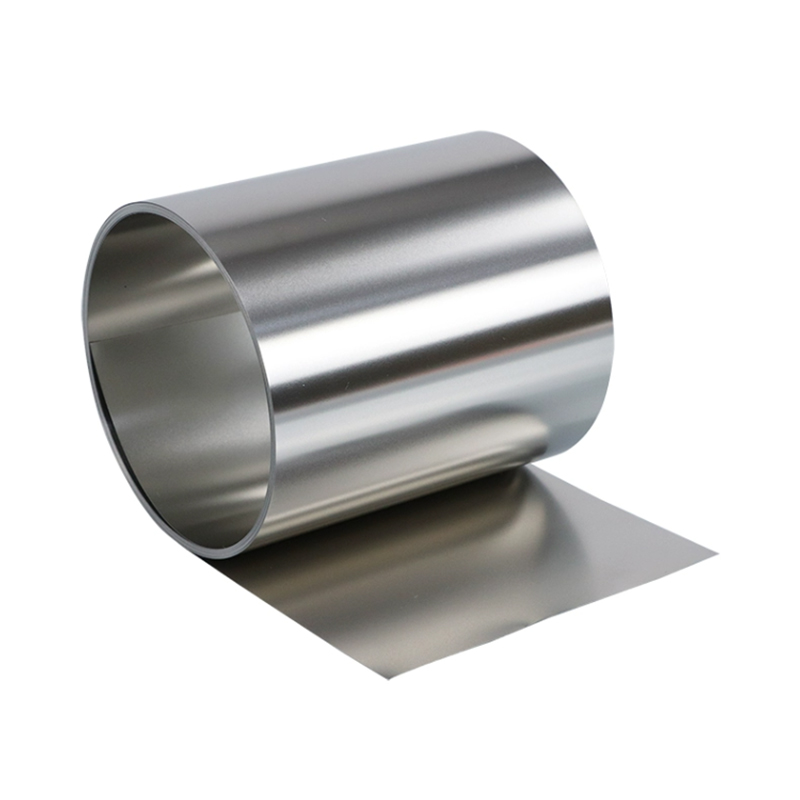

Hastelloy C4 Coil

Hastelloy C4 Coil is a high-performance nickel-based alloy that offers exceptional resistance to corrosion and high-temperature environments. It is a prime choice for applications that require durability, reliability, and corrosion resistance in extreme conditions.

Hastelloy C4 Coil is characterized by its excellent mechanical properties, including high strength, ductility, and fatigue resistance. It offers excellent resistance to acids, alkalis, and a wide range of corrosive media. This unique combination of properties makes Hastelloy C4 Coil an excellent choice for a wide range of industrial applications, such as chemical processing, oil and gas production, power generation, and more.

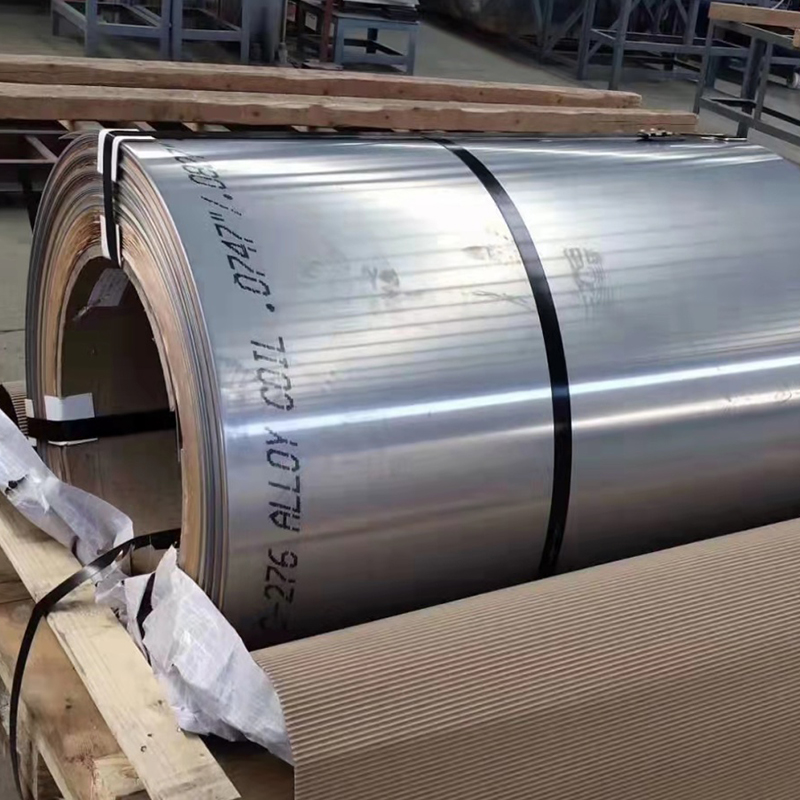

Hastelloy C4 Coil is available in various forms, including sheet, plate, and coil. It can be supplied in different grades to meet specific requirements for strength, corrosion resistance, and other properties. The coil form offers a convenient way to handle and process the material, making it ideal for large-scale industrial projects.

Hastelloy C4 Coil is processed using state-of-the-art techniques to ensure its quality and consistency. Our experienced team of experts provides comprehensive technical support and assistance throughout the entire process, from material selection to processing and installation. We also offer customization options to meet specific requirements and ensure that your Hastelloy C4 Coil solution is tailored to your unique needs.

When you choose Hastelloy C4 Coil from us, you can rest assured that you are getting the highest quality material from a trusted manufacturer. We have a reputation for excellence and are committed to providing our customers with the best possible service and support. Contact us today to learn more about Hastelloy C4 Coil and how it can meet your industrial needs.

| Product Name: Hastelloy C4 Coil |

| Ni | Cr | Fe | C | Mn | Si | Mo | Co | Ti | P | S | |

| Min | Balance | 14.5 | 14.0 | ||||||||

| Max | 17.5 | 3.0 | 0.009 | 1.0 | 0.05 | 17.0 | 2.0 | 0.7 | 0.02 | 0.01 |

| Density | 8.42 g/cm³ |

| Thermal Conductivity | 13 W/m·K |

| Thermal Expansion | 11.3 µm/m·K |

| Specific Heat Capacity | 0.41 J/g·K |

| Electrical Resistivity | 1.01 x 10⁶ Ω·m |

| Mechanical Properties |

| Tensile Strength | Up to 690 MPa |

| Yield Strength | Up to 345 MPa |

| Elongation | 30% |

| Hardness | HB 250 max |