Hastelloy C4 Pipe

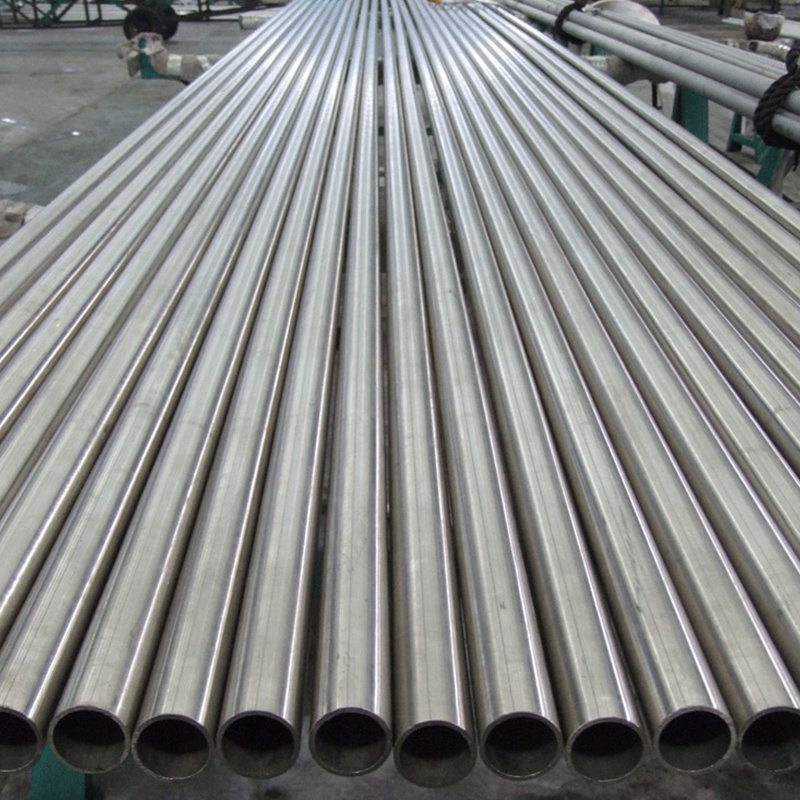

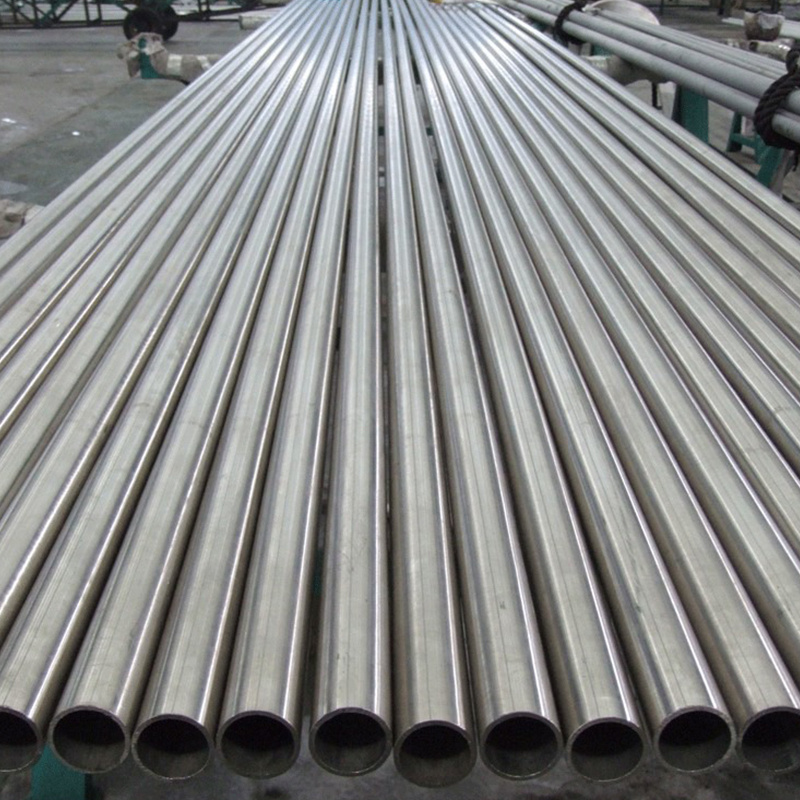

The exceptional corrosion resistance of Hastelloy C4 pipe makes it an excellent choice for use in environments where exposure to acids, alkalis, and other corrosive substances is common. Its exceptional strength allows it to withstand high temperatures and pressures, making it suitable for use in severe service conditions. Hastelloy C4 pipe also offers good formability and fabricability, allowing it to be bent, shaped, and welded without losing its mechanical properties.

The specific properties of Hastelloy C4 pipe make it an excellent choice for use in a variety of industrial applications. It is commonly used in the chemical processing industry, where it is exposed to highly corrosive substances. It is also used in the oil and gas industry, where it must withstand high temperatures and pressures. Hastelloy C4 pipe is also suitable for use in the power generation industry, as well as in the pulp and paper industry.

Hastelloy C4 pipe is produced to exacting standards, ensuring consistent quality and performance. The material is available in a variety of sizes and thicknesses, allowing it to be customized to meet specific application needs. It can be supplied in straight lengths or coiled, depending on the preference of the end user.

In conclusion, Hastelloy C4 pipe is a high-performance alloy that offers exceptional corrosion resistance, strength, and other beneficial properties. Its unique combination of properties makes it an excellent choice for use in various industrial applications, including the chemical processing industry, oil and gas industry, power generation industry, and pulp and paper industry. Hastelloy C4 pipe can be custom-designed to meet specific application needs and is produced to exacting standards to ensure consistent quality and performance.

| Product Name: GH4169 Pipe |

| The chemical composition of Hastelloy C4 Pipe is as follows: |

| Ni | Cr | Fe | C | Mn | Si | Mo | Co | Ti | P | S | |

| Min | Balance | 14.5 | 14.0 | ||||||||

| Max | 17.5 | 3.0 | 0.009 | 1.0 | 0.05 | 17.0 | 2.0 | 0.7 | 0.02 | 0.01 |

| Mechanical properties | Tensile strength: ≥235MPa |

| Yield strength: ≥115MPa | |

| Elongation: ≥35% | |

| Hardness: ≤220HB |