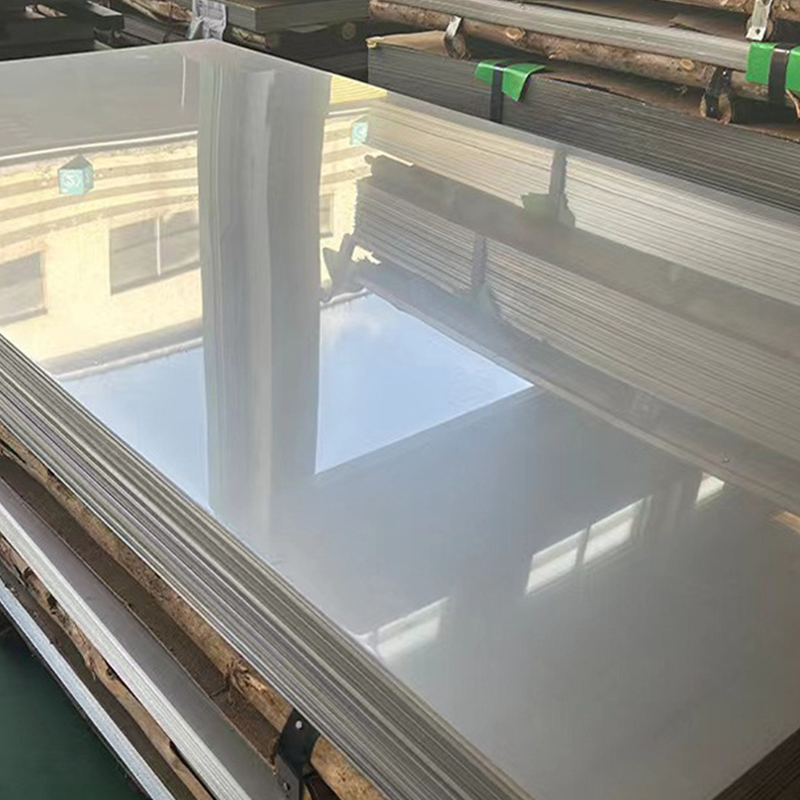

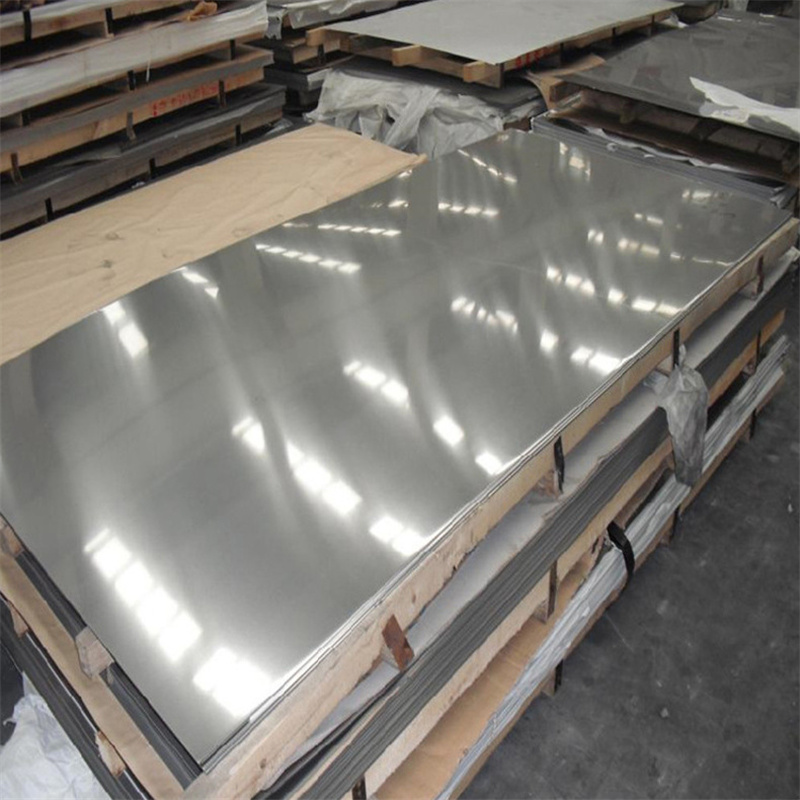

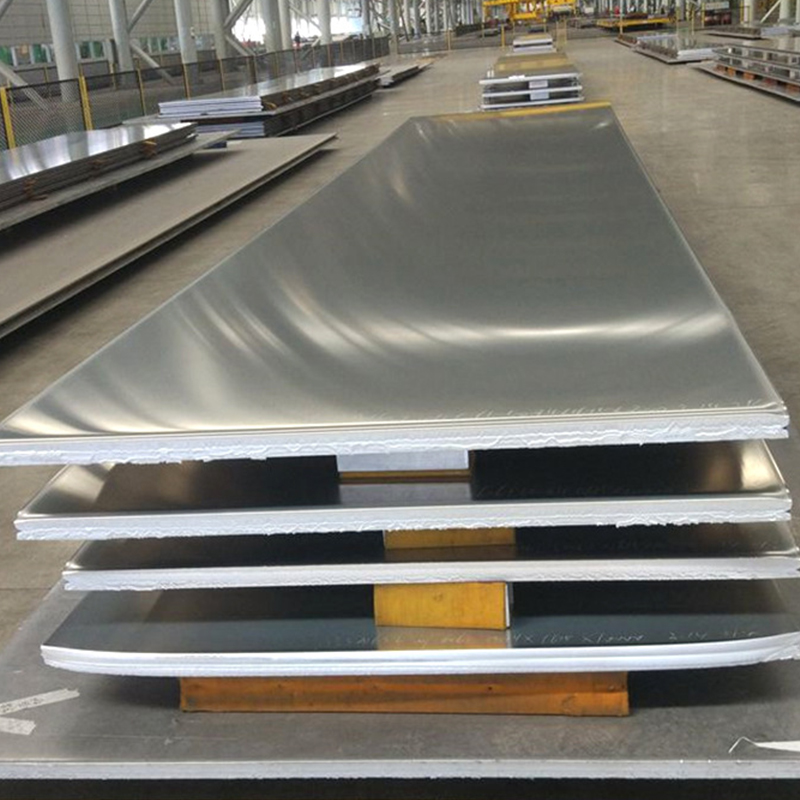

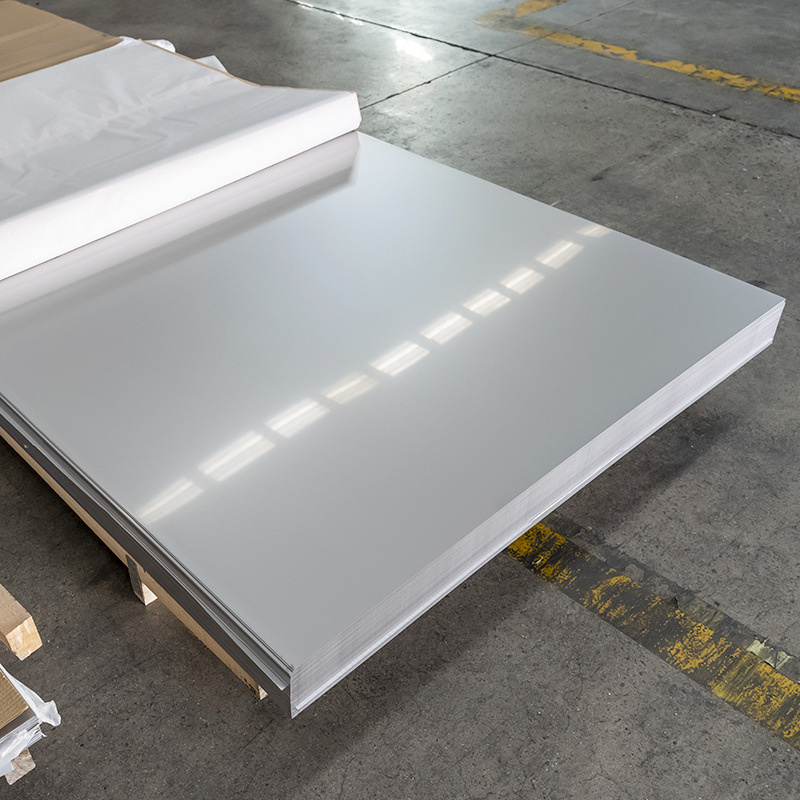

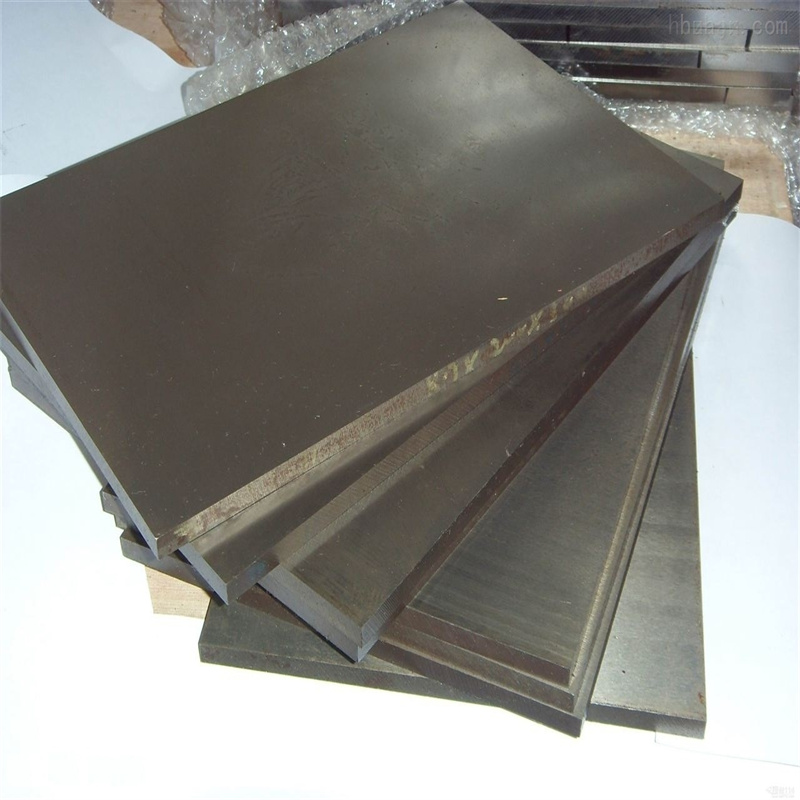

Incoloy 800 Alloy Plate

Incoloy 800 Alloy Plate is a high-performance material designed to excel in demanding high-temperature and corrosive environments. Composed of nickel, iron, and chromium, this alloy offers exceptional strength, oxidation resistance, and corrosion resistance. The Incoloy 800 Alloy Plate is a crucial component in various industries where reliability and durability are paramount.

High Temperature Capability: Incoloy 800 Alloy Plate maintains its mechanical integrity at elevated temperatures, making it an ideal choice for applications in heat-treating equipment, furnace components, and other high-temperature environments.

Corrosion Resistance: The alloy demonstrates excellent resistance to corrosion, including both oxidizing and reducing conditions. This property makes it suitable for use in chemical processing, petrochemical applications, and other corrosive environments.

Oxidation Resistance: Incoloy 800 Alloy exhibits superior resistance to oxidation, ensuring long-term performance in applications such as heat exchangers and combustion chambers.

Formability and Fabrication: With good ductility and formability, Incoloy 800 Alloy Plate allows for ease of fabrication, machining, and forming. This versatility contributes to its widespread use in various industrial processes.

| Chemical Processing | Chemical reactors |

| Heat exchangers | |

| Petrochemical equipment |

| Power Generation | Gas turbine components |

| Heat recovery steam generators |

| Aerospace | Aircraft ducting systems |

| Combustion chambers |

| Heat Treatment | Annealing boxes |

| Radiant tubes |

| Specifications | Material Form: Plates |

| Standard: ASTM B409 |

| Quality Assurance | Incoloy 800 Alloy Plate adheres to the highest industry standards, ensuring consistent quality and reliability. Rigorous testing procedures are implemented to guarantee the product's performance under challenging conditions. |

Incoloy 800 Alloy Plate is a top-tier solution for applications demanding a combination of high-temperature resistance and corrosion resistance. Its proven performance in critical industrial processes makes it a reliable choice for engineers and manufacturers.

For detailed product specifications, custom orders, or further inquiries, please contact our dedicated sales team.

| Product Name: Incoloy 800 Alloy Plate |

| Chemical Composition |

| Grade | C≤ | Mn≤ | Si≤ | S≤ | Cu≤ | Fe(min) | Ni | Cr | Al | Ti |

| 800 | 0.1 | 1.5 | 1.0 | 0.015 | 0.75 | 39.5 | 30.0-35.0 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 |

| Mechanical Properties | The alloy exhibits high strength and tensile properties, making it suitable for a range of load-bearing applications. Typical yield strength and tensile strength values for Incoloy 800 alloy plate range from 450 to 900 MPa and 550 to 1000 MPa, respectively. |

| Corrosion Resistance | Incoloy 800 alloy plate offers excellent corrosion resistance in a wide range of environments. It is highly resistant to acids, alkalis, and various other corrosive media. The protective oxide layer formed on the surface of the material provides excellent passive corrosion resistance. |

| Temperature Resistance | Incoloy 800 alloy plate can withstand temperatures ranging from cryogenic to elevated temperatures up to 980°C (1795°F). It maintains its mechanical properties and corrosion resistance even at high temperatures. |

| Weldability | Incoloy 800 alloy plate is weldable using various welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and manual metal arc welding (MMAW). Post-weld annealing may be required to restore the material's ductility and corrosion resistance. |