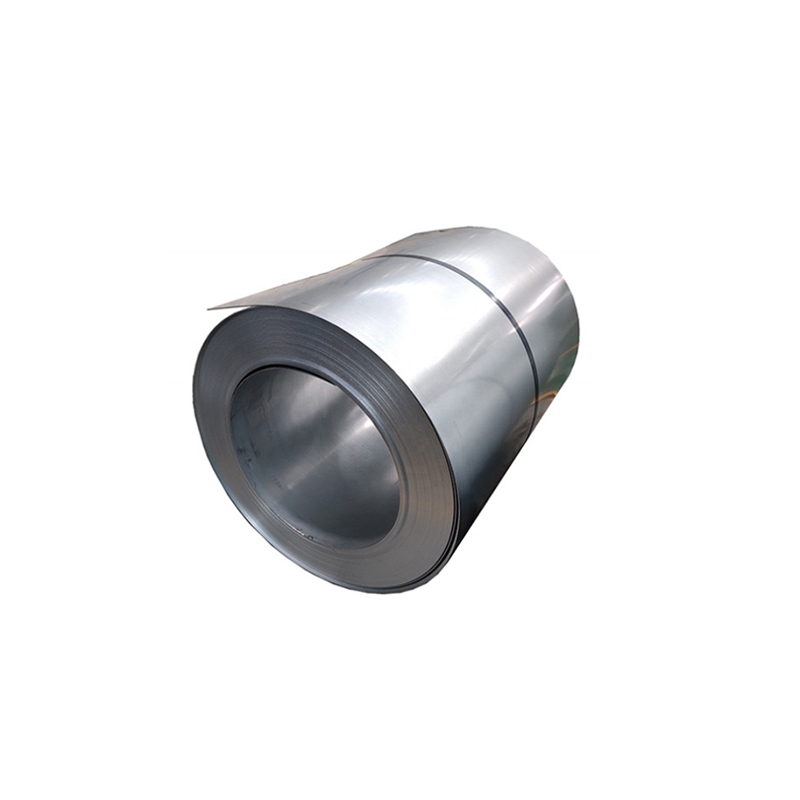

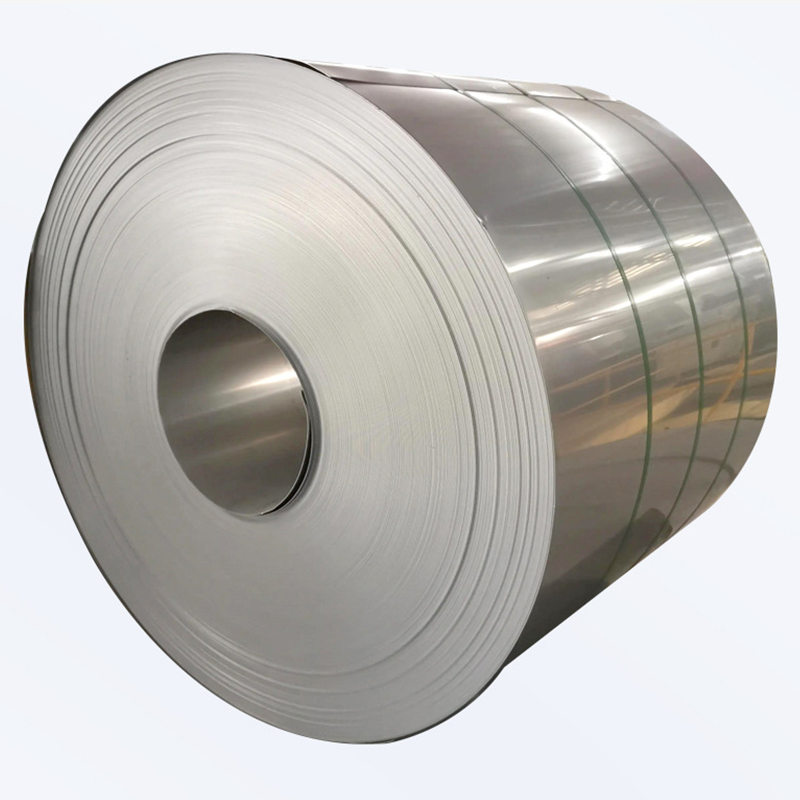

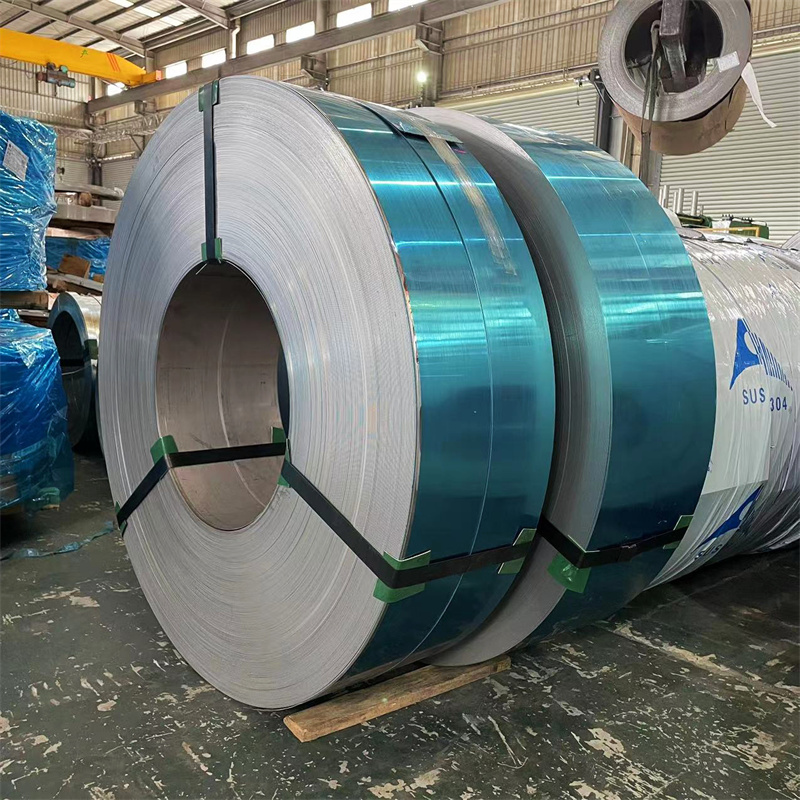

Incoloy 800 Coil

Incoloy 800 coil is a high-performance nickel-chromium-iron alloy that offers exceptional resistance to corrosion and high-temperature environments. It is widely used in a range of industries, including chemical processing, oil and gas exploration, and power generation.

Incoloy 800 coil is a highly versatile material that excels in extreme environments. Its exceptional corrosion resistance, high-temperature strength, and good weldability make it an excellent choice for a range of industries that require high-performance materials. As a result, Incoloy 800 coil has become a go-to choice for demanding applications where reliability and longevity are paramount.

Incoloy 800 coil is known for its exceptional resistance to chloride-ion stress corrosion cracking (SCC), making it an ideal choice for severe corrosive environments. It also has excellent high-temperature strength and good weldability. The addition of titanium and aluminum to the alloy imparts corrosion resistance, while the chromium content provides excellent oxidation resistance.

Incoloy 800 coil offers a combination of excellent corrosion resistance, high-temperature strength, and good weldability. It maintains its properties across a wide range of temperatures and is suitable for both welded and non-welded applications. The material is also easy to fabricate, making it cost-effective for a variety of industrial uses.

Due to its exceptional corrosion resistance and high-temperature strength, Incoloy 800 coil is often used in extreme environments where other materials fail. It is commonly used in:

Chemical processing equipment, including reactors, piping, and storage tanks

Heat exchangers and boilers in power plants and oil refineries

Oil and gas exploration equipment, such as drill strings, pipelines, and downhole tools

Aerospace components that require high-temperature strength and corrosion resistance

Marine applications, including shipbuilding and offshore platforms

| Product Name: Incoloy 800 Coil |

| Grade | C≤ | Mn≤ | Si≤ | S≤ | Cu≤ | Fe(min) | Ni | Cr | Al | Ti |

| 800 | 0.1 | 1.5 | 1.0 | 0.015 | 0.75 | 39.5 | 30.0-35.0 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 |

| Mechanical Properties | Tensile Strength: 690 to 965 MPa (Recommended Operating Temperature Range) |

| Yield Strength: 345 to 515 MPa | |

| Elongation: 25 to 50% | |

| Brinell Hardness: 180 to 210 HB |

| Thermal Properties | Melting Point: 1350°C to 1400°C (2452°F to 2552°F) |

| Thermal Conductivity: 11.6 W/m·K at 20°C (68°F) |

| Corrosion Resistance | Incoloy 800 Coil is highly resistant to acids, alkalis, and other corrosive media. It offers excellent resistance to chloride-ion stress corrosion cracking and is suitable for use in severe corrosive environments. |

| Weldability | Incoloy 800 Coil can be welded using standard fusion welding techniques. Pre- and post-weld annealing may be required for optimal properties, depending on the specific application and welding process used. |