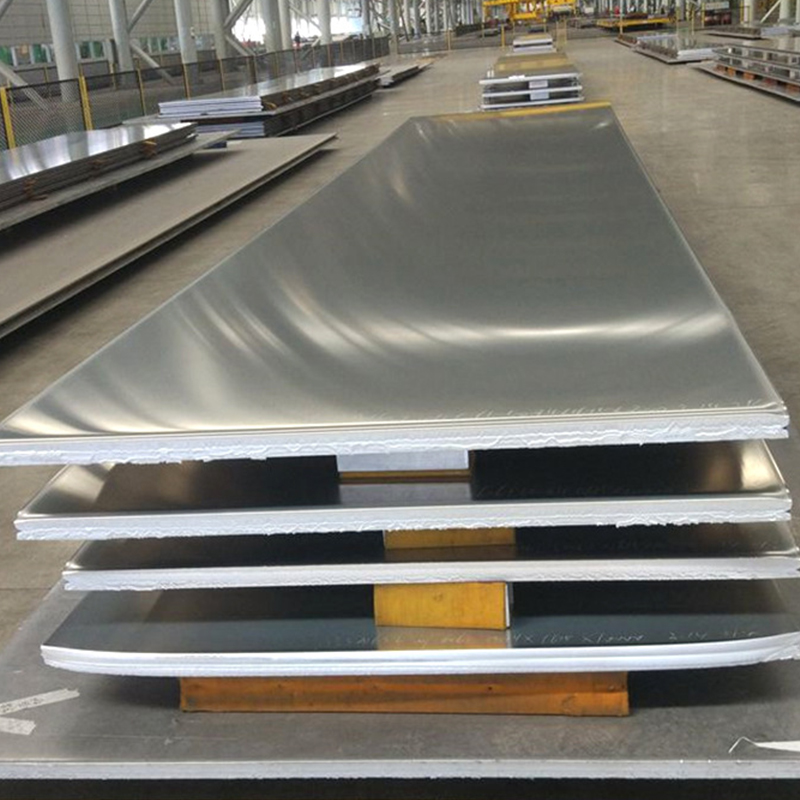

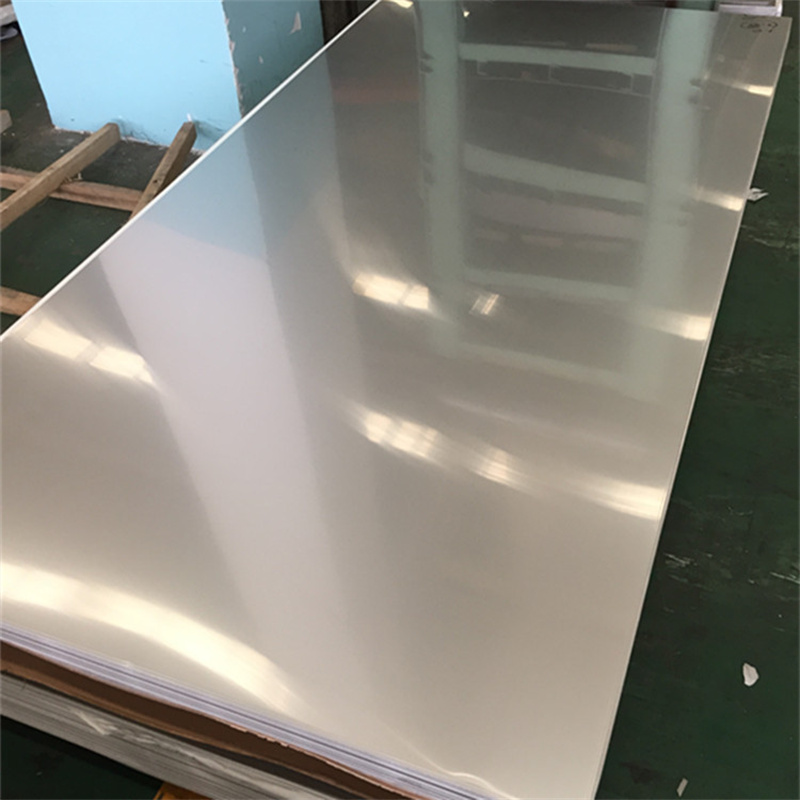

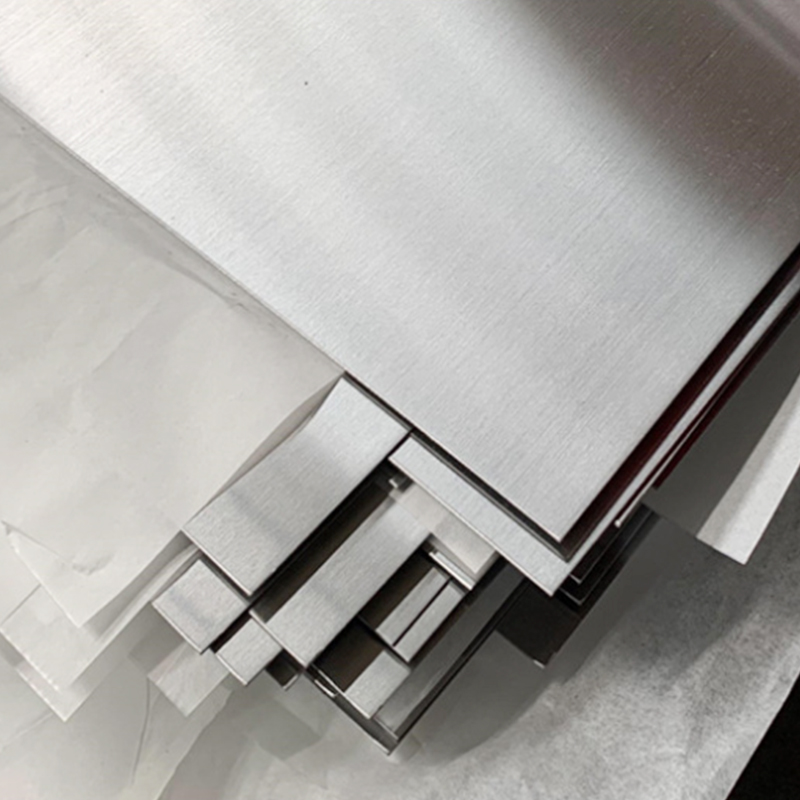

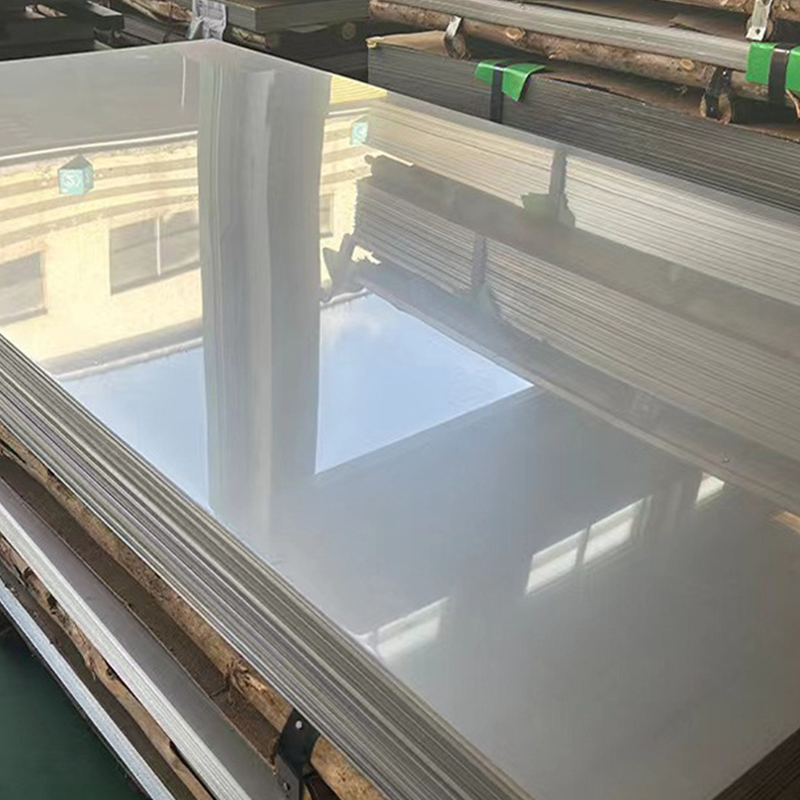

Incoloy 800HT Alloy Plate

Incoloy 800HT is a high strength, high corrosion resistance alloy sheet, widely used in petrochemical, electric power, Marine engineering and other fields. It has good fatigue resistance, high temperature performance and processing performance, and can work stably in high temperature and corrosive environment for a long time.

The chemical composition of Incoloy 800HT alloy sheet mainly includes Fe, Ni, Cr, C, Mn, Si and other elements, of which the content of Ni and Cr elements is higher, respectively 30% and 21%. The proportions of these elements have been carefully designed to give the Incoloy 800HT excellent corrosion resistance and high temperature properties.

Incoloy 800HT alloy sheet has excellent mechanical properties, high tensile strength and yield strength, and good elongation. Incoloy 800HT maintains its strength and hardness well at high temperatures and is not prone to deformation and breakage. In addition, the alloy sheet also has good welding properties and processing properties, which is convenient for cutting, bending, drilling and other processing operations.

In terms of applications, Incoloy 800HT alloy plates are mainly used in the manufacture of reactors, heat exchangers, pipelines and other equipment, which can withstand a variety of harsh working environments. For example, in the petrochemical sector, Incoloy 800HT alloy plates can be used to make oil tanks, pipelines and other equipment, which can withstand high temperatures and acidic media corrosion; In the field of power, the alloy sheet can be used to manufacture boilers, chimneys and other equipment, which can withstand high temperatures and oxidative corrosion.

In conclusion, Incoloy 800HT alloy sheet is a high performance metal material with a wide range of applications. Its excellent corrosion resistance, high temperature and mechanical properties make it an ideal material choice in many fields.

| Product Name: Incoloy 800HT Alloy Plate |

| Composition | Primary elements: nickel (approximately 30%), iron, chromium |

| Other elements: carbon, molybdenum, titanium, aluminum, silicon, manganese |

| Mechanical Properties | Tensile strength: minimum 690 MPa (96 ksi) |

| Yield strength: minimum 345 MPa (50 ksi) | |

| Elongation: minimum 35% in 2 in. (50 mm) | |

| Hardness: Brinell hardness of approximately 180-210 HB |

| Corrosion Resistance | Resistant to a wide range of corrosive environments, including acids, alkalis, and chlorides Excellent resistance to stress corrosion cracking and pitting corrosion |

| Temperature Resistance | High-temperature creep resistance up to 870°C (1600°F) for short periods of time |

| Long-term use temperatures up to 704°C (1300°F) |