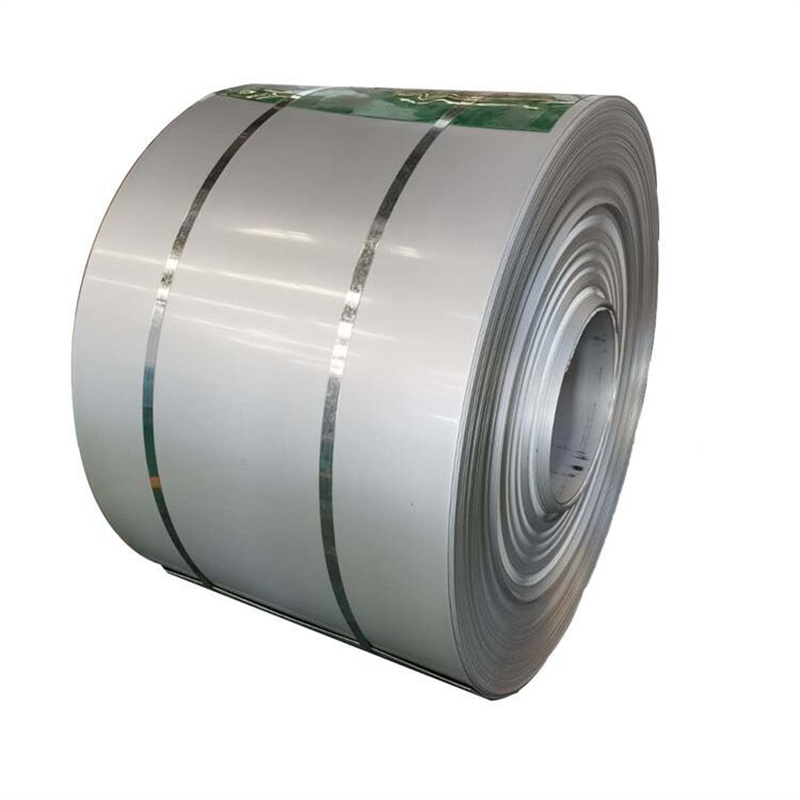

Incoloy 825 Coil is a nickel-iron-chromium alloy that offers a unique combination of properties, making it an excellent choice for a wide range of industrial applications. With its exceptional corrosion resistance, strength, and temperature resistance, Incoloy 825 Coil is often used in severe service environments where durability and reliability are paramount.

The primary alloying elements in Incoloy 825 Coil include nickel, iron, chromium, molybdenum, and copper. These elements are carefully balanced to provide the alloy with its exceptional corrosion resistance. Incoloy 825 Coil is highly resistant to a variety of corrosive environments, including acids, alkalis, and sea water. This corrosion resistance, coupled with its good mechanical properties, makes Incoloy 825 Coil an excellent choice for use in chemical processing, pollution control, and other corrosive service applications.

In addition to its corrosion resistance, Incoloy 825 Coil also offers excellent strength and temperature resistance. It has a high tensile strength and provides good creep resistance even at elevated temperatures. This makes Incoloy 825 Coil suitable for use in high-temperature applications such as gas turbines, furnaces, and heat exchangers.

Incoloy 825 Coil is also easy to fabricate, making it well-suited for a range of manufacturing processes. It can be easily welded, machined, and formed, allowing for efficient processing and fabrication of components and assemblies.

In summary, Incoloy 825 Coil is a highly versatile and durable metallic material that offers exceptional corrosion resistance, strength, and temperature resistance. Its wide range of applications includes chemical processing equipment, pollution control systems, and high-temperature components in power generation and other industrial processes. With its superior performance and ease of processing, Incoloy 825 Coil is a valuable addition to the toolbox of engineers and designers working in demanding environments.