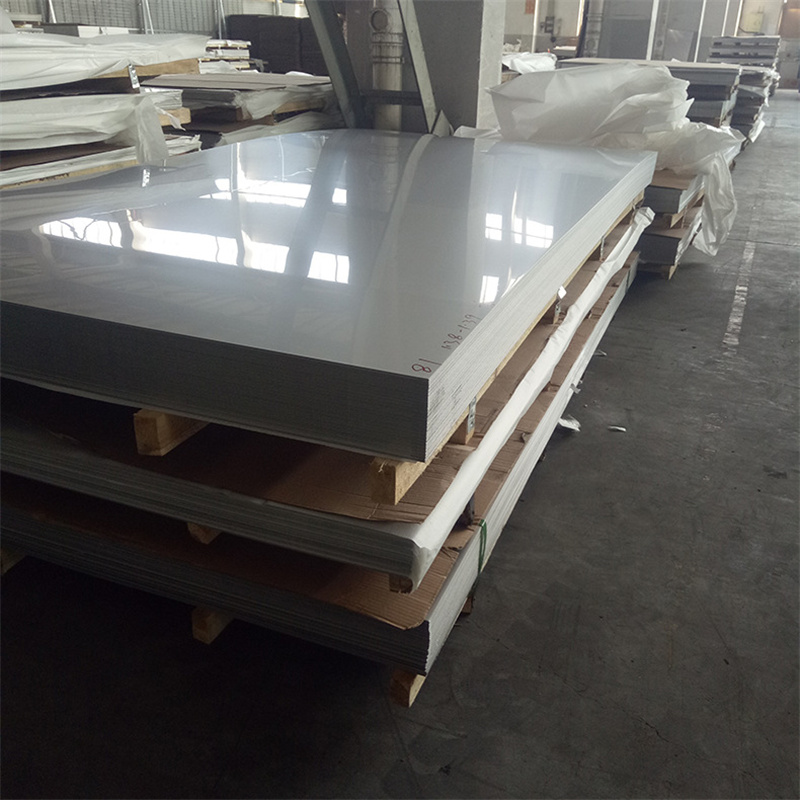

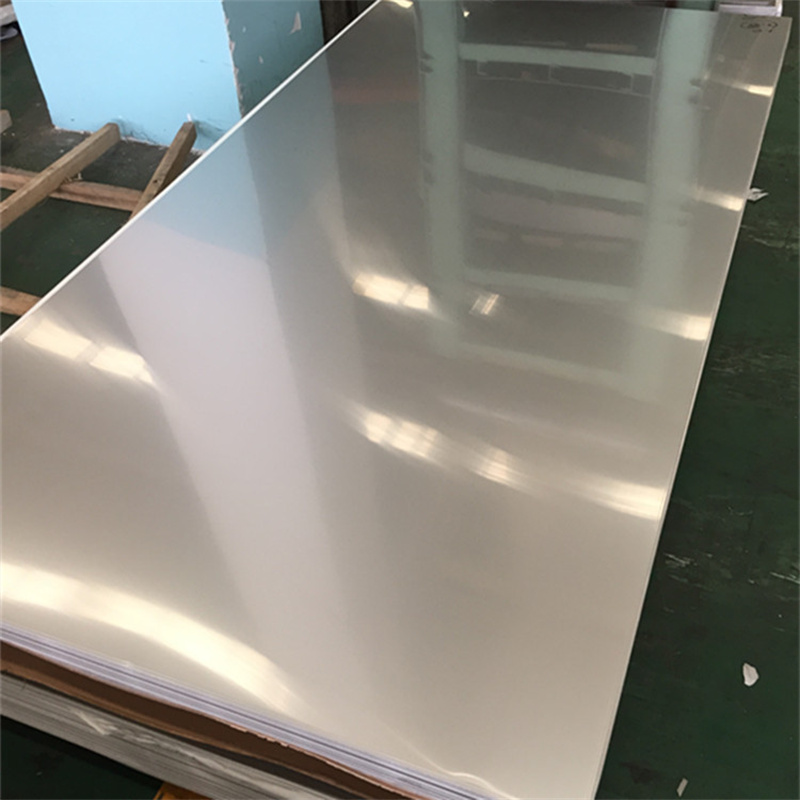

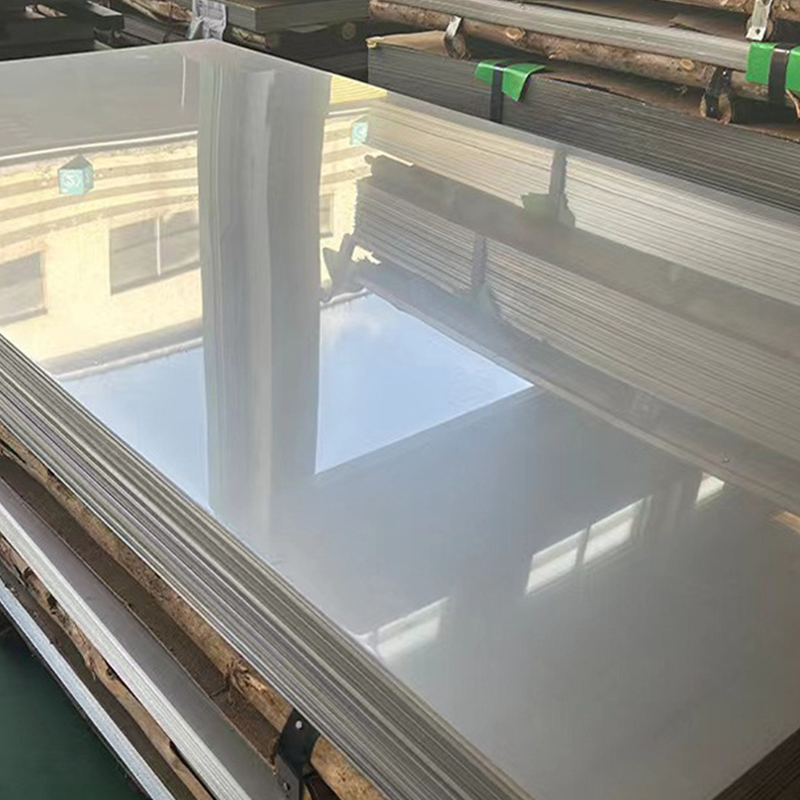

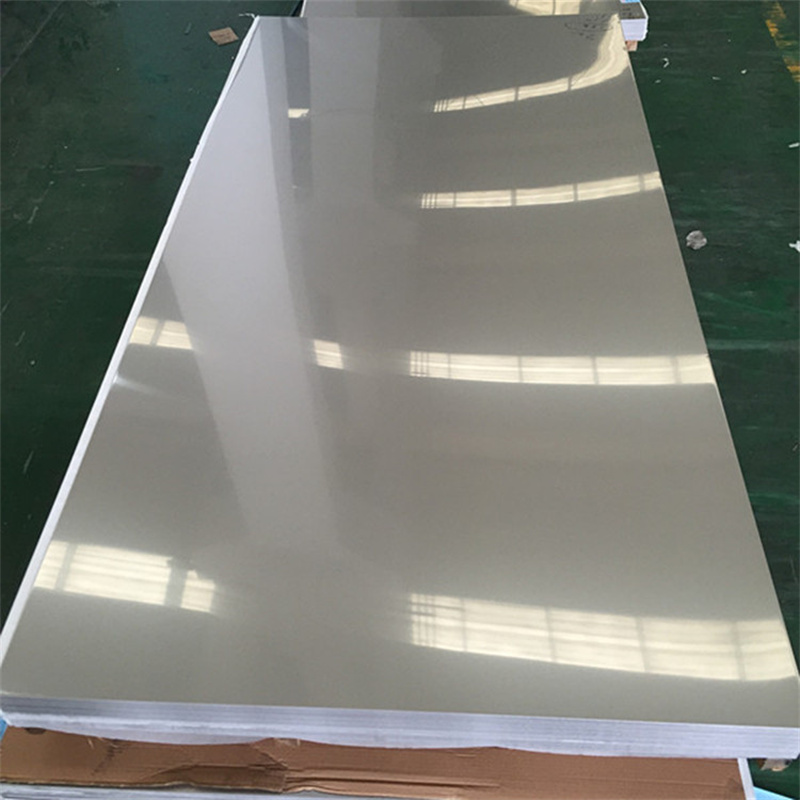

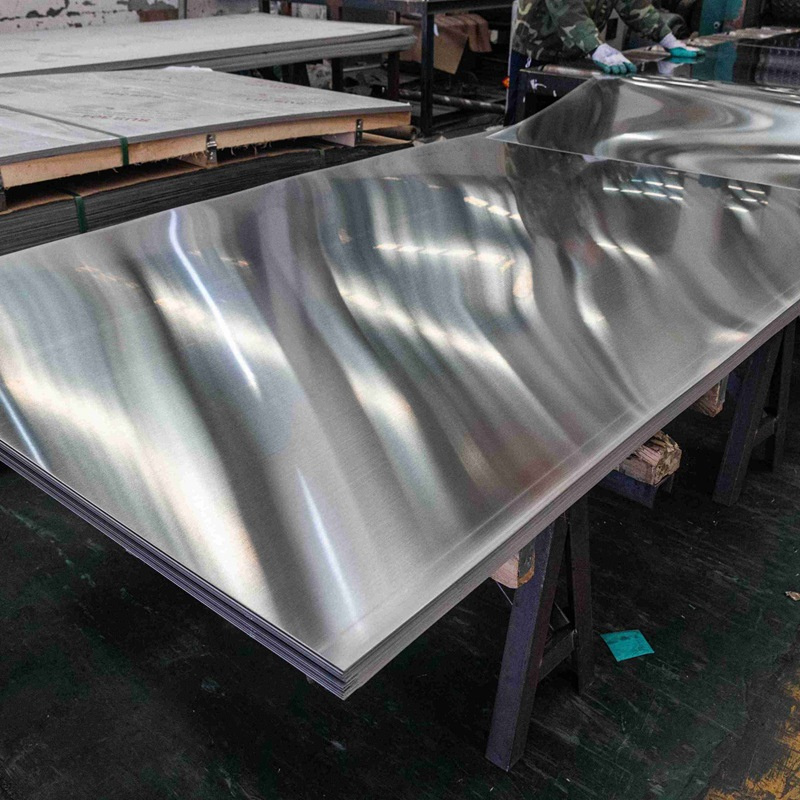

Inconel 600 Alloy Plate

Inconel 600 alloy plate is a high-performance material, renowned for its exceptional corrosion resistance and elevated temperature strength. It finds applications in a range of industries, including chemical processing, power generation, and oil and gas exploration.

Inconel 600 alloy plate is a nickel-based alloy, containing approximately 72% nickel, 15% iron, 8% chromium, and 5% carbon. It offers excellent resistance to acids, alkalis, and other corrosive media. This property makes it an ideal material for use in extreme chemical environments, where other alloys would quickly corrode.

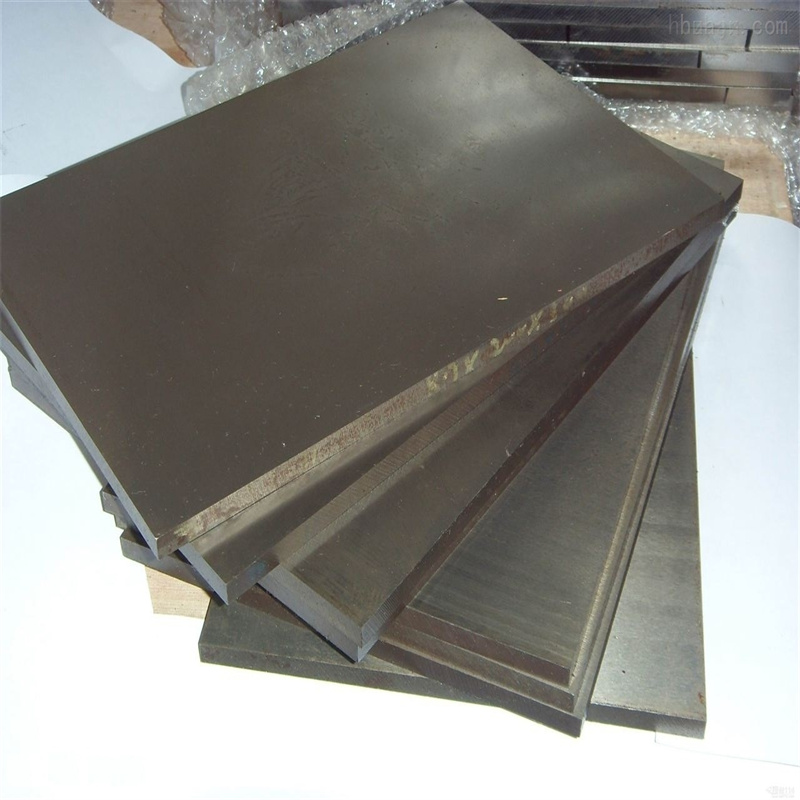

Another key advantage of Inconel 600 alloy plate is its exceptional high-temperature strength. It can withstand temperatures as high as 1200°C without significant loss of strength or ductility. This makes it an excellent choice for components that require longevity in high-temperature environments, such as furnace liners, heat exchangers, and reactor vessels.

In addition to its corrosion resistance and high-temperature strength, Inconel 600 alloy plate also offers good mechanical properties. It has high tensile strength and excellent fatigue resistance, which enables it to withstand cyclic loading without failure. This makes it suitable for use in components that experience repeated stress, such as valves, piping systems, and pressure vessels.

The versatility of Inconel 600 alloy plate extends beyond its corrosion resistance and high-temperature strength. It can be processed using various techniques, including forging, casting, and sheet metal forming. It also has good weldability, allowing it to be repaired or joined using various welding processes.

In summary, Inconel 600 alloy plate is a highly versatile material that offers exceptional corrosion resistance, high-temperature strength, and good mechanical properties. Its adaptability and reliability make it an excellent choice for a wide range of industrial applications, where durability and performance are paramount.

| Product Name: Inconel 600 Alloy Plate |

| Chemical composition |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Mechanical Properties | The mechanical properties of Inconel 600 alloy Plate are dependent on the material's processing history, including annealing treatment and heat treatment. Typical mechanical properties include yield strength and tensile strength. Typical yield strength ranges from 48 ksi to 71 ksi, while typical tensile strength ranges from 72 ksi to 98 ksi. The elongation at fracture ranges from 15% to 35%. |

| Physical Properties | Inconel 600 alloy Plate has a density of approximately 8.48 g/cm³, with a melting range from 2377°F to 2487°F. It has a thermal expansion coefficient similar to that of incoloy and hastelloy alloys. The coefficient of thermal expansion at room temperature is about 7.7 µin/in-°F. |

| Corrosion Resistance | Inconel 600 alloy Plate offers excellent corrosion resistance in a wide range of environments, including oxidizing and reducing acids, alkalis, and various corrosive gases and solutions. It is highly resistant to pitting and crevice corrosion, even at elevated temperatures. The protective oxide layer formed on the surface of Inconel 600 provides excellent corrosion resistance. |

| Fabrication and Heat Treatment | Inconel 600 alloy Plate can be fabricated using standard metalworking techniques such as cutting, forming, and welding. It is annealed between 1950°F and 2150°F for a minimum of two hours, then air-cooled or furnace-cooled for best mechanical properties. Post-weld annealing may be required for certain applications. |