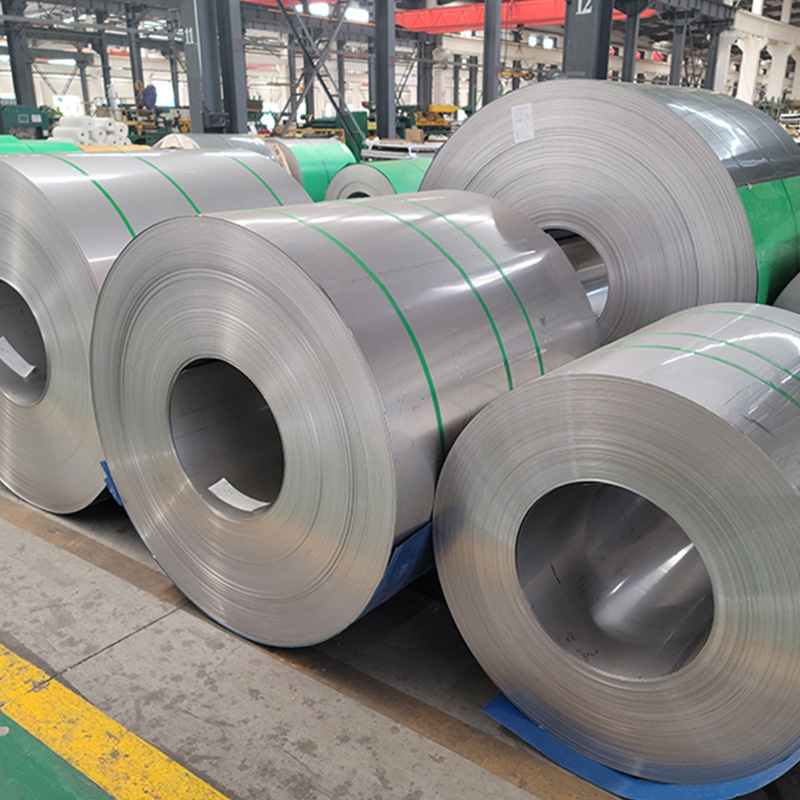

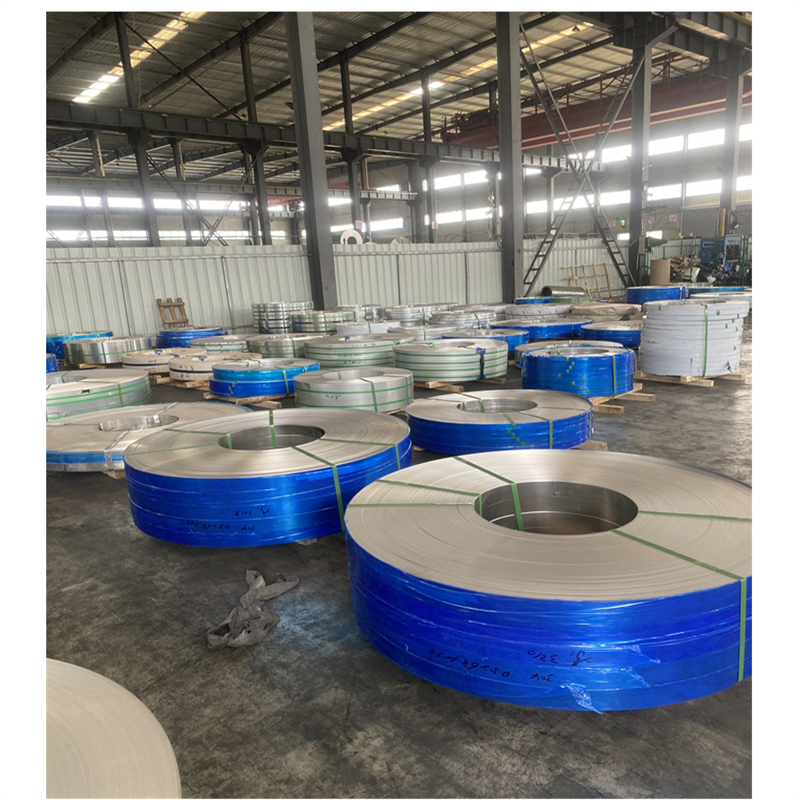

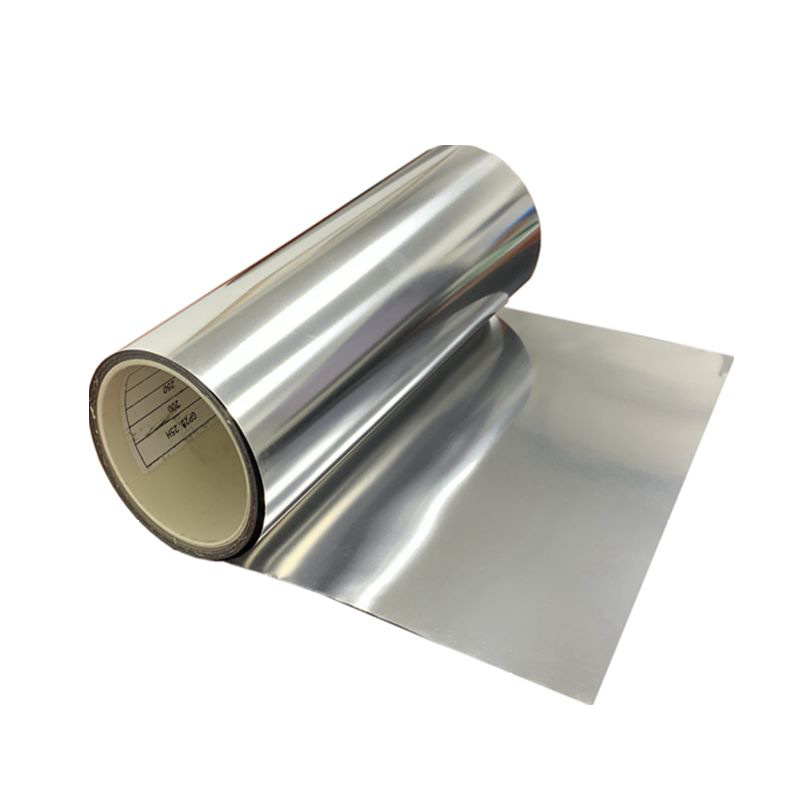

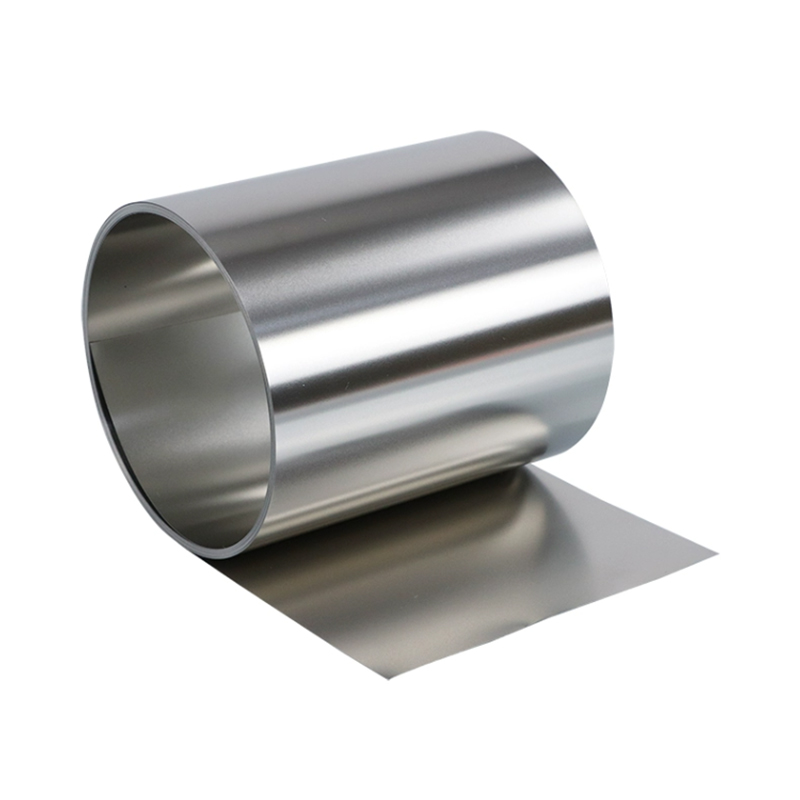

Inconel 601 Coil

Inconel 601 Coil is a high-performance alloy, renowned for its exceptional resistance to corrosion and high-temperature environments. It offers an ideal combination of mechanical strength, creep resistance, and excellent stress-rupture properties, making it a material of choice for a range of demanding applications.

The Coil's outstanding corrosion resistance is a result of its protective oxide film, which forms naturally in high-temperature environments. This film effectively prevents further oxidation and ensures that the material maintains its structural integrity, even in corrosive environments. This makes Inconel 601 Coil an excellent choice for use in chemical processing, petroleum refining, and other industries where exposure to corrosive substances is commonplace.

The material's exceptional resistance to high temperatures is a result of its unique microstructure and chemical composition. Inconel 601 Coil offers excellent thermal stability, even at temperatures exceeding 700°C. This makes it an excellent choice for use in heat-resistant applications, such as furnace components, industrial heat exchangers, and aircraft exhaust systems.

In addition to its exceptional corrosion and high-temperature resistance, Inconel 601 Coil offers excellent mechanical properties. It exhibits high strength and creep resistance, making it suitable for use in applications where components are subject to high stress or continuous loading. It is widely used in the power generation, aerospace, and transportation industries.

The Inconel 601 Coil's comprehensive set of properties, such as its exceptional corrosion resistance, high-temperature stability, and mechanical strength, make it an invaluable material for a range of high-performance applications. It has become a go-to choice for engineers and designers who demand exceptional performance and durability in their products and systems.

To ensure the best performance of Inconel 601 Coil, it is essential to handle and process the material properly. Fabricators should follow stringent processing guidelines to ensure that the material's properties are not compromised. Proper heat treatment, controlled annealing, and precision machining are essential to achieve the desired mechanical properties and corrosion resistance.

In conclusion, Inconel 601 Coil offers an unparalleled combination of corrosion resistance, high-temperature stability, and mechanical strength. Its adaptability and reliability make it a material of choice for a range of demanding applications across various industries. As technological advancements continue to drive the need for more advanced materials, Inconel 601 Coil's exceptional performance and durability will remain at the forefront of high-performance applications.

| Product Name: Inconel 601 Coil |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Key Properties | High corrosion resistance |

| Excellent mechanical properties | |

| High-temperature resistance | |

| Good weldability |

| Mechanical Properties | Yield Strength: ≥ 45 ksi |

| Tensile Strength: ≥ 90 ksi | |

| Elongation: ≥ 25% | |

| Hardness: ≤ 220 Brinell |

| Thermal Properties | Melting Point: 2375°F (approximate) |

| Thermal Conductivity: 13 W/m·K at 20°C | |

| Thermal Expansion: 7.3 μm/m·K at 20°C |

| Applications | Inconel 601 Coil is used in various industries where high-temperature and corrosion resistance are essential. Some of the common applications include: |

| Automotive exhaust systems | |

| Heat exchangers and boilers | |

| Petroleum refining equipment | |

| Chemical processing equipment | |

| Aerospace components and engines | |

| Power generation components (e.g., turbine blades) |