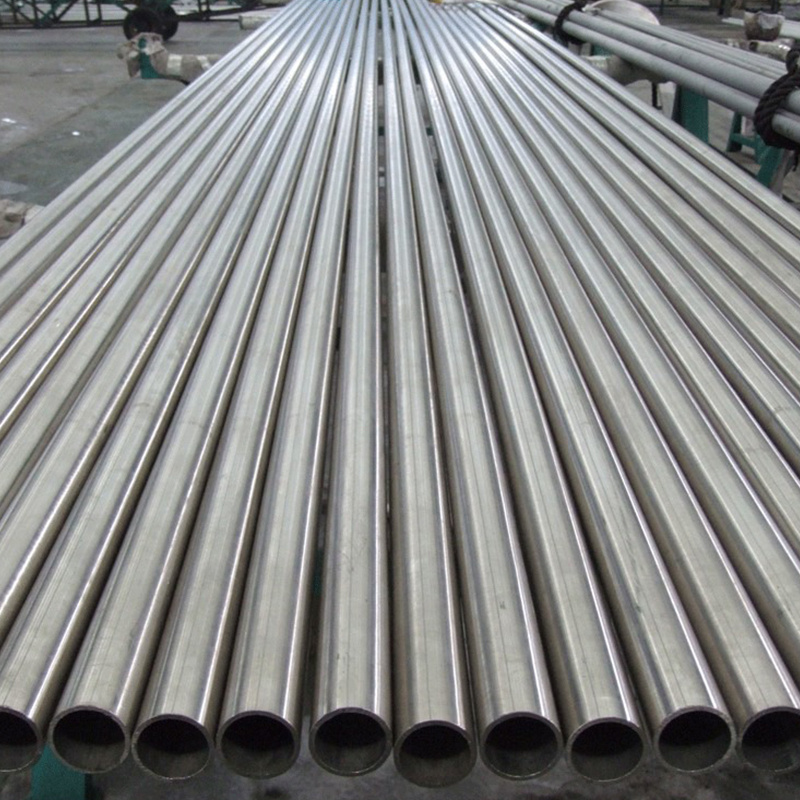

Inconel 601 Pipe

Inconel 601 Pipe is a high-performance nickel-based alloy, renowned for its exceptional resistance to corrosion and high-temperature environments. Its unique properties make it an excellent choice for a wide range of industrial applications, where durability and reliability are essential.

High Temperature Resistance: Inconel 601 Pipe offers excellent resistance to high temperatures, making it suitable for use in extreme heat environments. It retains its strength and stability even at temperatures up to 1300°F, making it an excellent choice for high-temperature applications.

Corrosion Resistance: Inconel 601 Pipe is highly resistant to a variety of corrosive environments, including acids, alkalis, and oxidizing agents. Its nickel-based composition provides a protective oxide layer that helps prevent corrosion, making it suitable for use in aggressive chemical environments.

Mechanical Properties: Inconel 601 Pipe offers excellent mechanical properties, including high tensile strength and creep resistance. It maintains its strength over a wide range of temperatures, making it suitable for both cryogenic and high-temperature applications.

Weldability: Inconel 601 Pipe is easy to weld, making it suitable for fabrication of complex components and assemblies. The alloy can be joined using a variety of welding techniques, ensuring efficient and reliable joining of components.

Inconel 601 Pipe is used in a wide range of industries where its exceptional properties are required. Some of the main applications include:

Heat Exchangers: Inconel 601 Pipe is commonly used in the manufacture of heat exchangers due to its high-temperature resistance and corrosion resistance. It ensures efficient heat transfer while maintaining structural integrity under demanding conditions.

Petrochemical Industry: The petrochemical industry often requires materials that can withstand extreme temperatures and corrosive environments. Inconel 601 Pipe provides a robust solution for piping systems, valves, and other process equipment.

Aerospace Applications: The aerospace industry demands materials that exhibit high strength and stability under demanding conditions. Inconel 601 Pipe meets these requirements and is commonly used in aircraft engines and other critical components.

Power Generation: Inconel 601 Pipe is suitable for use in power generation plants, particularly in areas where high temperatures and corrosive exhaust gases are present. It provides durability and reliability in steam turbines, boiler components, and other critical parts.

In conclusion, Inconel 601 Pipe offers an excellent combination of high-temperature resistance, corrosion resistance, mechanical properties, and weldability. Its adaptability to various industrial applications makes it a versatile metal solution for demanding applications where durability and reliability are essential.

| Product Name: ASTM B167 Inconel 601 Seamless Pipe |

| Chemical Composition |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Mechanical Properties |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |