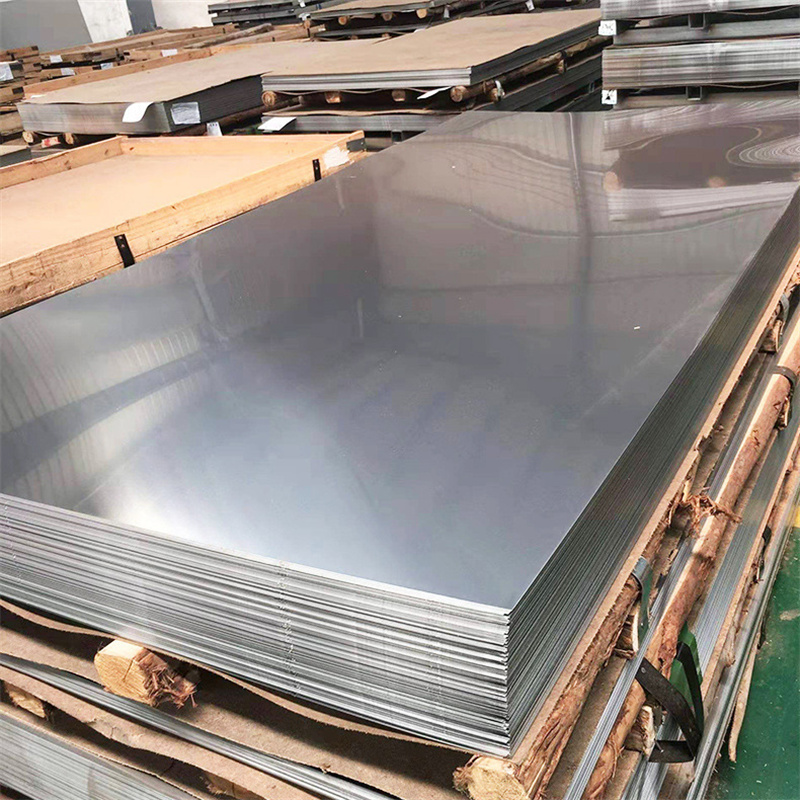

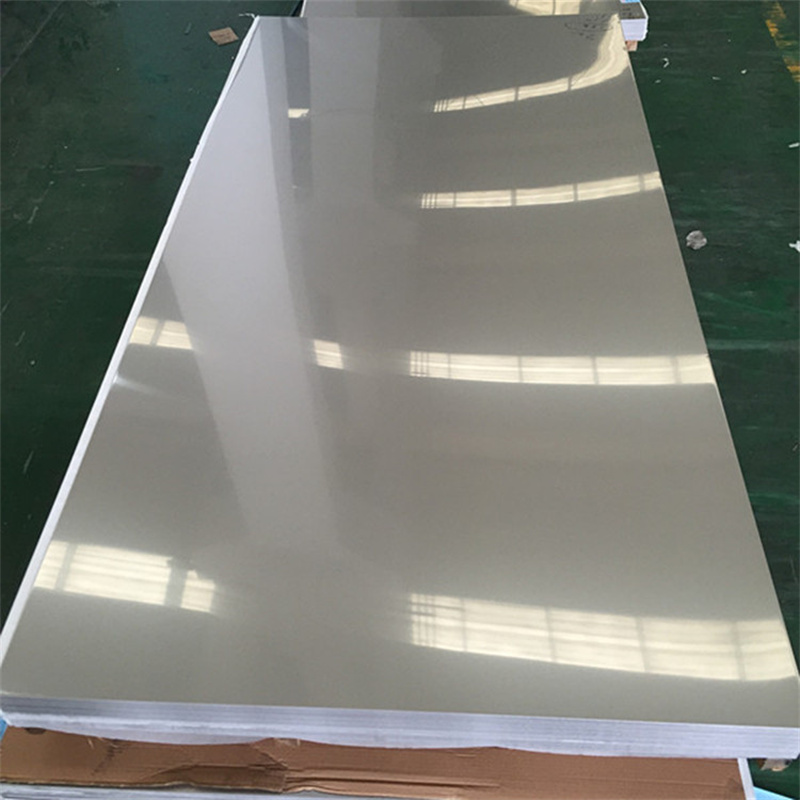

Inconel 625 Alloy Plate

Inconel 625 alloy plate is a nickel-chromium-based superalloy that offers exceptional resistance to corrosion and high-temperature oxidation. It is widely used in various industries, particularly in aerospace, chemical processing, and oil and gas exploration, due to its unique combination of strength, ductility, and weldability.

Exceptional Corrosion Resistance - Inconel 625 alloy plate offers superior resistance to a wide range of corrosive environments, including acids, alkalis, and chlorides. This makes it an excellent choice for use in severe chemical processing applications where other materials would quickly corrode or fail.

High-Temperature Performance - Inconel 625 alloy plate has exceptional high-temperature strength and stability. It can withstand temperatures up to 1000°C (1832°F) without losing its mechanical properties, making it well-suited for use in high-temperature gas turbines, jet engines, and other high-performance applications.

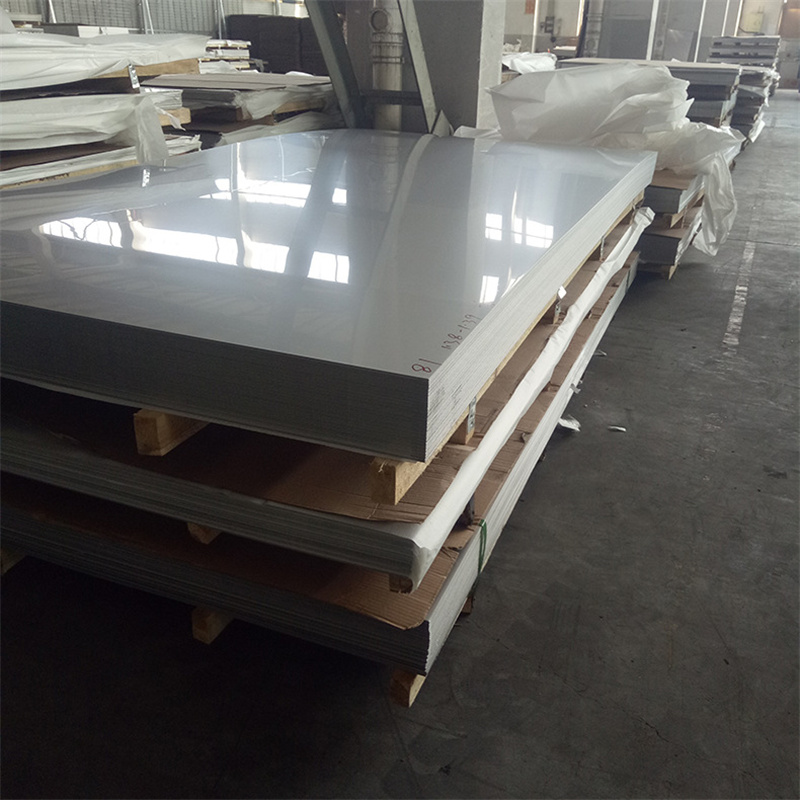

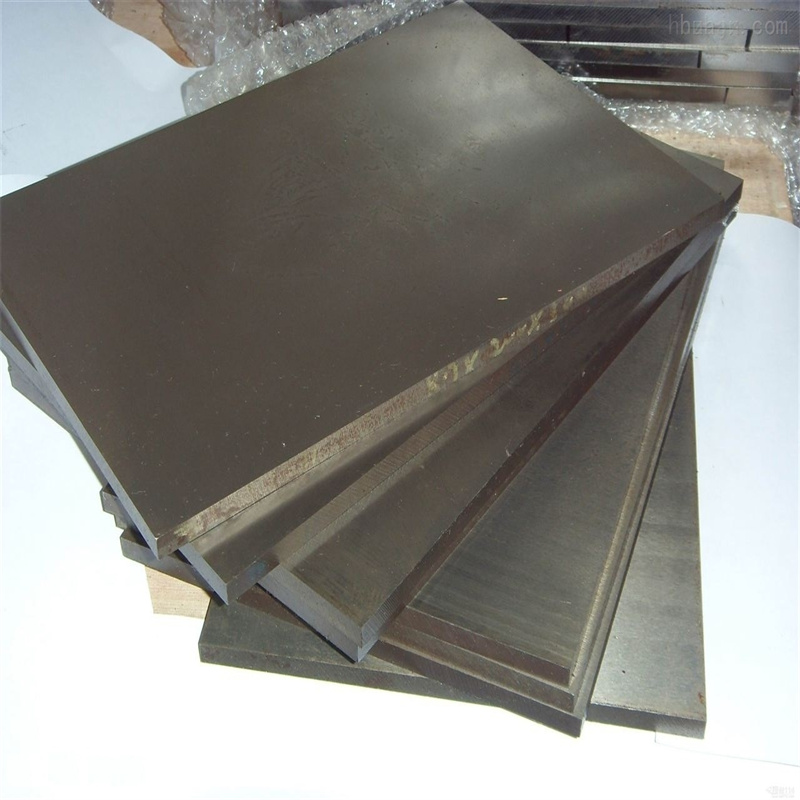

Dense, Strong, and Tough - Inconel 625 alloy plate has a high density, providing excellent strength and stiffness. It is also tough and ductile, making it easy to form and fabricate into a variety of shapes and sizes without cracking or brittleness.

Easy to Machinability - Inconel 625 alloy plate can be easily machined using conventional machine tools and cutting tools. This makes it cost-effective to fabricate components and assemblies using this material.

Due to its exceptional corrosion resistance and high-temperature performance, Inconel 625 alloy plate is used in a wide range of critical applications:

Aerospace Components - Inconel 625 alloy plate is used in the manufacture of jet engine components, such as turbine blades and vanes, combustion chambers, and other critical components that require high-temperature strength and corrosion resistance.

Chemical Processing Equipment - Inconel 625 alloy plate is commonly used in the construction of chemical processing equipment, including reactors, tanks, piping systems, and other components that must withstand severe corrosive environments.

Energy Production Facilities - Inconel 625 alloy plate is employed in the construction of energy production facilities such as nuclear reactors, solar energy systems, and wind turbines due to its high-temperature strength and corrosion resistance.

Automotive Components - Inconel 625 alloy plate is used in the production of automotive components that require high-temperature strength and corrosion resistance, such as exhaust systems and turbochargers.

In conclusion, Inconel 625 alloy plate offers a unique combination of properties that make it an excellent choice for a range of critical applications that demand exceptional corrosion resistance and high-temperature performance. Its widespread use in the aerospace, chemical processing, energy production, and other industries highlights its versatility and adaptability to meet the most demanding requirements.

| Product Name: Inconel 625 Alloy Plate |

| Chemical Composition |

| Ni | Cr | Co | Mo | Fe | Mn | Al |

| 58% min | 20%-23% | 1.0%Max | 8%-10% | 5.0% Max | 0.5 Max | 0.4 Max |

| C | Cu | Si | S | Ti | P | Cb+Ta |

| 0.1% Max | 0.5 Max | 0.5 Max | 0.015 Max | 0.4 Max | 0.015 Max | 3.15%- 4.15% |

| Mechanical Properties | Yield Strength: ≥280 MPa |

| Ultimate Tensile Strength: ≥550 MPa | |

| Elongation: ≥15% | |

| Reduction of Area: ≥45% |

| Thermal Properties | Melting Point: 2300°C - 2450°C |

| Thermal Conductivity: 11 W/m-°C at 20°C |