Inconel 625 Coil

Inconel 625 Coil is a high-performance nickel-based alloy that offers exceptional resistance to corrosion and high-temperature environments. It is widely used in a variety of industries, including aerospace, chemical processing, and oil and gas production.

Inconel 625 Coil is characterized by its excellent mechanical properties, including high strength, ductility, and fatigue resistance. It offers excellent creep resistance even at elevated temperatures, making it suitable for applications where components are exposed to long-term stress at high temperatures.

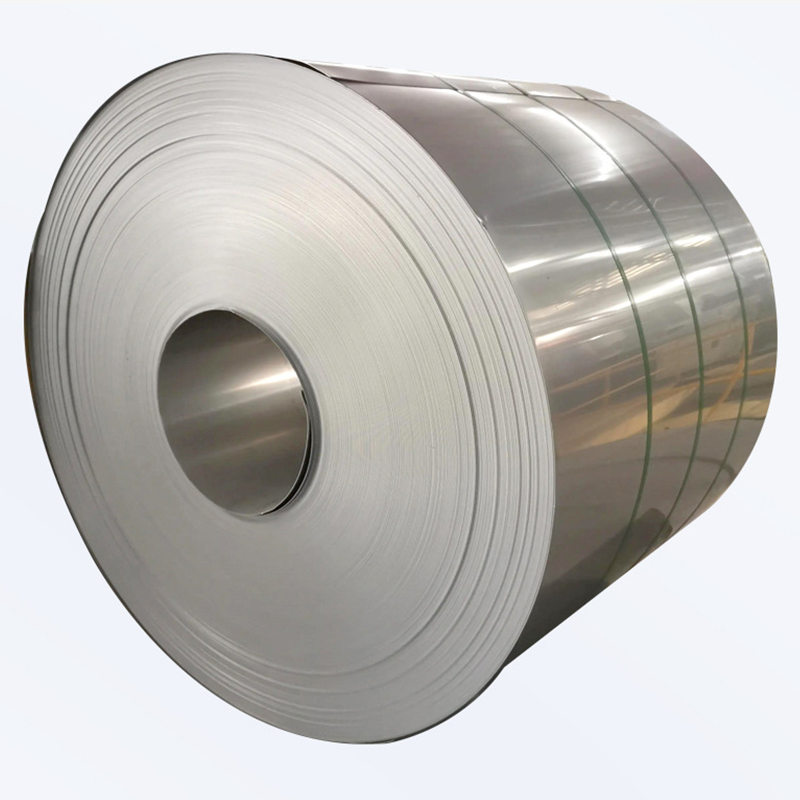

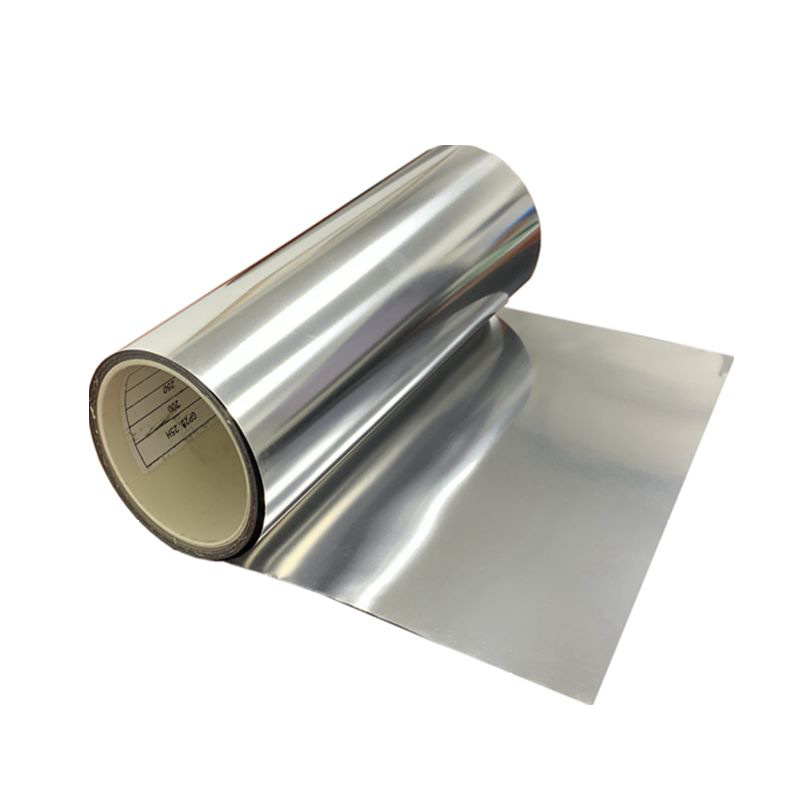

The coil is available in various gauges and dimensions to meet specific application requirements. It can be supplied in straight lengths or coiled for ease of handling and installation. The coil is wound tightly without gaps or overlaps, ensuring consistent quality and performance.

Inconel 625 Coil is processed using advanced techniques to ensure its quality and performance. The alloy is hot-rolled, cold-rolled, and annealed to achieve the desired mechanical properties and corrosion resistance. The coil is then finished with a protective coating to enhance its resistance to corrosion and improve its durability in harsh environments.

Inconel 625 Coil is used in a wide range of applications due to its exceptional corrosion resistance and high-temperature capabilities. Some common applications include:

Oil and gas production: The coil is used in the production of oil and gas due to its ability to withstand the corrosive nature of drilling fluids and other chemicals present in the production process. It is commonly used in pipelines, valves, and other critical components.

Chemical processing: Inconel 625 Coil is used in the manufacturing of chemicals due to its exceptional resistance to acids, alkalis, and other corrosive chemicals. It is ideal for use in reactors, piping systems, and other critical components in the chemical processing industry.

Aerospace: Inconel 625 Coil is used in aerospace applications due to its high-temperature capabilities and exceptional corrosion resistance. It is commonly used in aircraft engines, turbine blades, and other critical components where durability and reliability are essential.

Automotive: The coil is also used in automotive applications where components are exposed to harsh environments. It is commonly used in exhaust systems, fuel lines, and other critical components that require resistance to corrosion and high temperatures.

In addition to these applications, Inconel 625 Coil is also used in marine, energy, and other industries where components require exceptional durability and performance under extreme conditions.

| Product Name: Inconel 617 Coil |

| Chemical Composition |

| Ni | Cr | Co | Mo | Fe | Mn | Al |

| 58% min | 20%-23% | 1.0%Max | 8%-10% | 5.0% Max | 0.5 Max | 0.4 Max |

| C | Cu | Si | S | Ti | P | Cb+Ta |

| 0.1% Max | 0.5 Max | 0.5 Max | 0.015 Max | 0.4 Max | 0.015 Max | 3.15%- 4.15% |

| Material Specification | Material: Inconel 625 Coil |

| Melting Point: 2310°C | |

| Thermal Conductivity: 1.2 W/m·K at 20°C | |

| Thermal Expansion Coefficient: 11.4 x 10^-6 K^-1 |

| Mechanical Properties | Yield Strength: 380 MPa at 20°C |

| Tensile Strength: 730 MPa at 20°C | |

| Elongation: 22% at 20°C | |

| Hardness: HRB 93-103 at 20°C |

| Chemical Properties | Maximum Oxidation Temperature: 1095°C in air |

| Resistance to acids: Excellent resistance to acids, except hydrochloric acid and nitric acid | |

| Resistance to alkalis: Excellent resistance to alkalis | |

| Resistance to salt solutions: Good resistance to salt solutions, except those containing chlorides or sulfates |

| Electrical Properties | Electrical Resistivity: 1.2 x 10^-6 Ω·m at 20°C |

| Thermal Conductivity: 1.2 W/m·K at 20°C | |

| Specific Heat Capacity: 0.12 J/g·K at 20°C | |

| Thermal Expansion Coefficient: 11.4 x 10^-6 K^-1 |