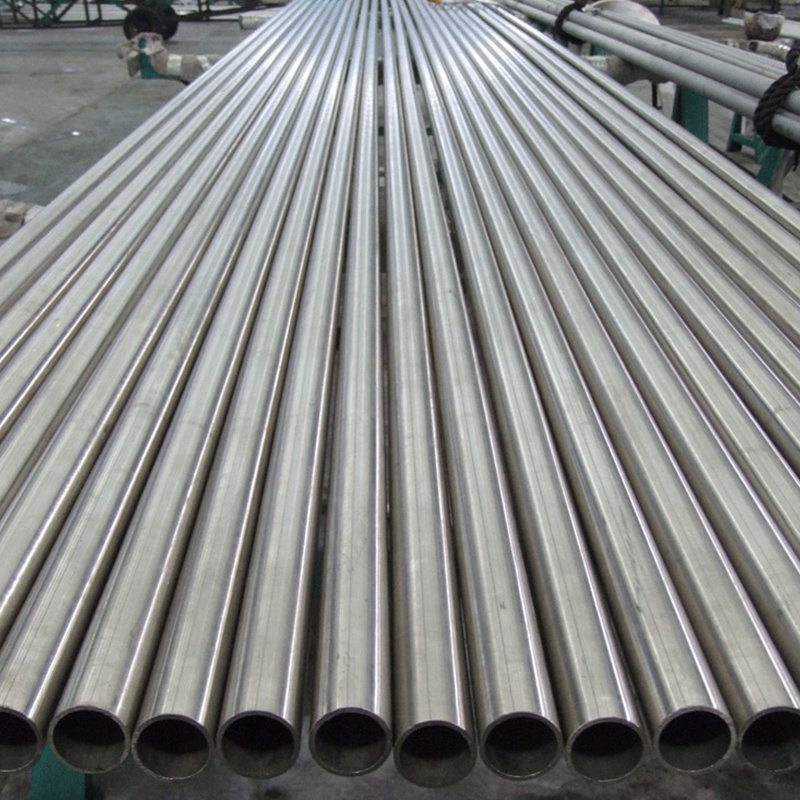

Inconel 625 pipe

Alloy 625 pipe is a high-performance metal alloy that offers exceptional resistance to corrosion and high temperatures. It is widely used in a range of industries, including aerospace, chemical processing, and oil and gas extraction. In this article, we delve into the unique properties and applications of this remarkable piping material.

Alloy 625 pipe is known for its exceptional mechanical properties, including high strength, ductility, and fatigue resistance. It has excellent corrosion resistance to a wide range of acids, alkalis, and oxidizing agents. Furthermore, it offers good resistance to stress corrosion cracking, making it an excellent choice for severe environments.

Another key advantage of Alloy 625 pipe is its exceptional high-temperature capabilities. It can withstand temperatures up to 1200°F (650°C) without significant loss of strength or corrosion resistance. This makes it an excellent choice for high-temperature applications in power generation, petrochemical processing, and other industries that require exposure to extreme heat.

Alloy 625 pipe is used in a variety of industries due to its unique combination of properties. One of the most common applications is in the oil and gas industry, where it is used for oil and gas pipeline systems. Its exceptional corrosion resistance and high-temperature capabilities make it an ideal material for transporting hydrocarbons over long distances.

In the aerospace industry, Alloy 625 pipe is used in aircraft engine components and fuel systems. Its high strength, fatigue resistance, and good thermal conductivity make it suitable for these demanding applications. It is also used in the chemical processing industry, where it is exposed to highly corrosive environments. Alloy 625 pipe excels in these conditions due to its excellent corrosion resistance and high-temperature capabilities.

In conclusion, Alloy 625 pipe offers an exceptional combination of mechanical properties, corrosion resistance, and high-temperature capabilities. Its adaptability and reliability make it a popular choice for a range of industries, including aerospace, chemical processing, and oil and gas extraction. As a result, it has become a go-to material for demanding applications that require exceptional performance under extreme conditions.

| Product Name: Inconel 625 pipe |

| Chemical Composition |

| Ni | Cr | Co | Mo | Fe | Mn | Al | C | Cu | Si | S | Ti | P | Cb+Ta |

| 58% min | 20%-23% | 1.0%Max | 8%-10% | 5.0% Max | 0.5 Max | 0.4 Max | 0.1% Max | 0.5 Max | 0.5 Max | 0.015 Max | 0.4 Max | 0.015 Max | 3.15%- 4.15% |

| Mechanical Properties | Tensile Strength: ≥110 ksi (≥765 MPa) |

| Yield Strength: ≥85 ksi (≥585 MPa) | |

| Elongation: ≥18% in 2" (≥50.8 mm) |

| Thermal Properties | Melting Point: 2640-2690°F (1450-1475°C) |

| Thermal Conductivity: 13 W/m·K at 20°C (69°F) | |

| Thermal Expansion: 13 μin/in·°F (70 μin/in·°C) at 20°C (69°F) |