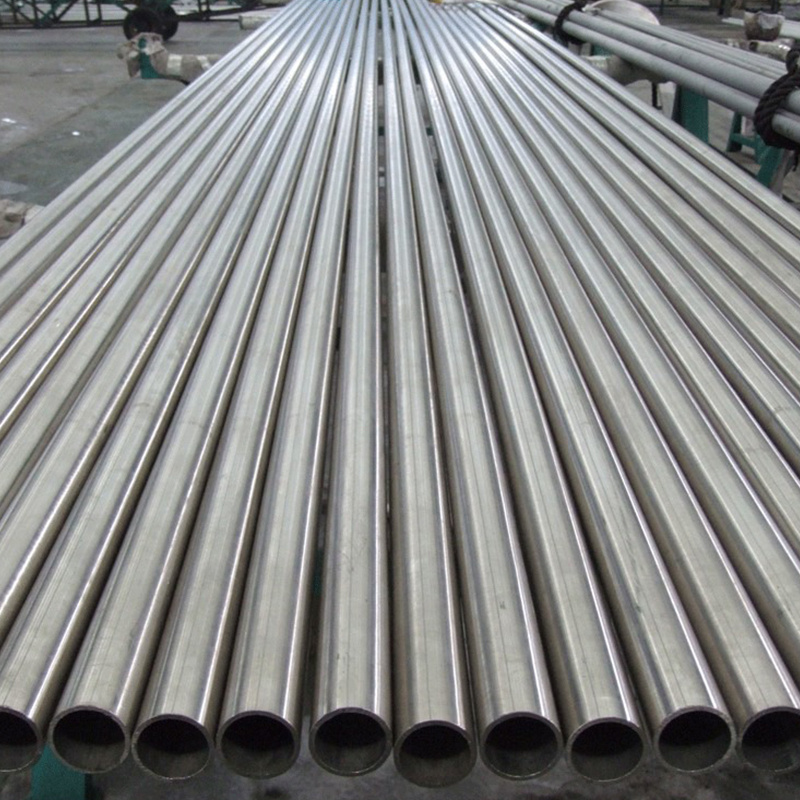

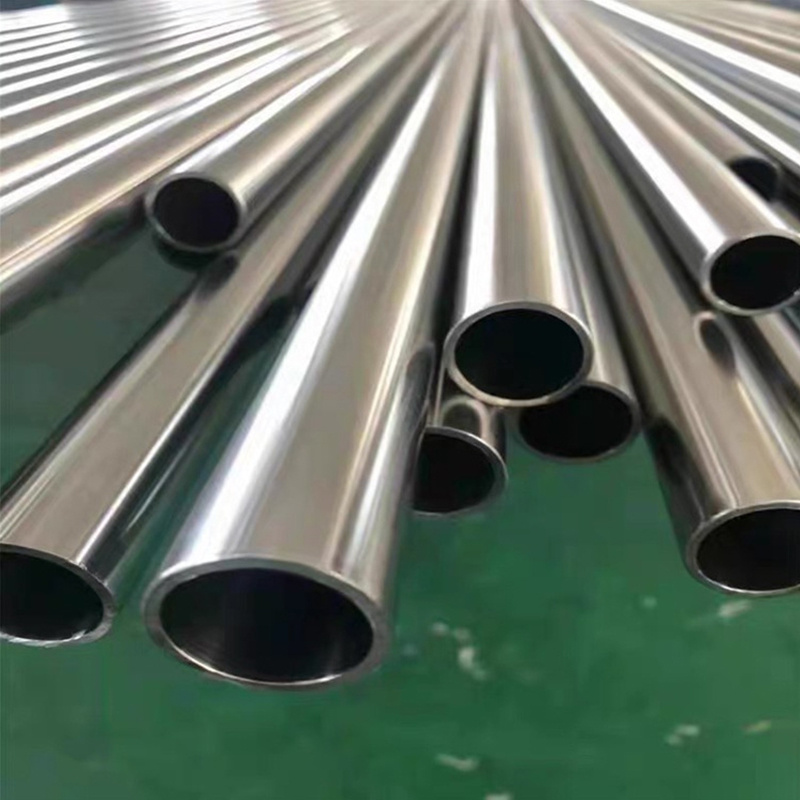

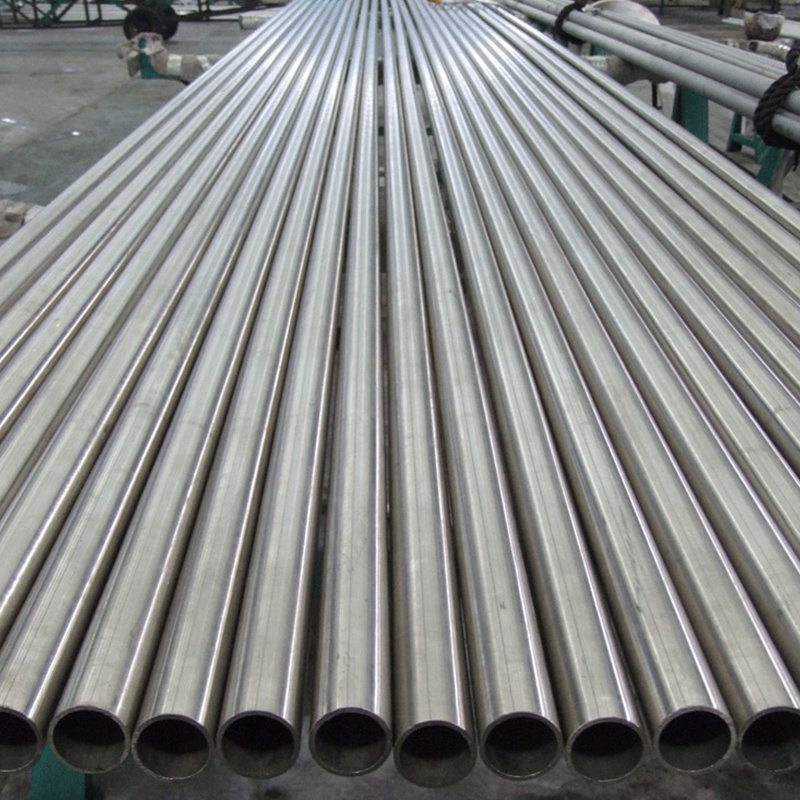

Inconel 718 pipe

Inconel 718's origin can be traced back to the 1960s, when it was first developed by Special Metals Corporation. Since then, it has become a go-to material for industries that require materials capable of withstanding extreme temperatures and harsh environments. The alloy's primary alloying elements include iron, cobalt, and chromium, which contribute to its exceptional mechanical properties and corrosion resistance.

One of the key features of Inconel 718 pipe is its exceptional tensile strength. It offers significantly higher tensile strength than many other nickel-based alloys, making it suitable for applications where heavy loads and stress are common. Its creep strength at high temperatures is also noteworthy, ensuring stability under extreme conditions.

Another noteworthy aspect of Inconel 718 pipe is its excellent resistance to corrosion and oxidation. The alloy's protective oxide layer prevents further corrosion, even in aggressive environments. This makes it an excellent choice for piping systems in chemical processing plants, oil and gas pipelines, and other industrial applications where exposure to corrosive agents is unavoidable.

In addition to its corrosion resistance, Inconel 718 pipe offers good resistance to a range of acids, alkalis, and other corrosive chemicals. Its excellent resistance to chloride-ion stress corrosion cracking further enhances its suitability for various challenging applications.

Inconel 718 pipe is available in a variety of sizes and wall thicknesses to meet the specific requirements of different applications. It can be fabricated using various techniques, such as bending, welding, and flanging, ensuring ease of installation and integration into existing systems.

The use of Inconel 718 pipe offers several advantages over other materials. Its high-temperature capabilities enable it to withstand temperatures well above the limits of other alloys. Its excellent mechanical properties, including tensile strength and ductility, make it suitable for a range of loading conditions. Additionally, its corrosion resistance significantly reduces the maintenance requirements and extends the service life of piping systems.

In conclusion, Inconel 718 pipe is a highly versatile and durable material that offers exceptional performance in extreme environments. Its combination of high tensile strength, excellent corrosion resistance, and good high-temperature capabilities make it an excellent choice for a range of industrial applications. As a result, Inconel 718 pipe is becoming increasingly popular in various industries where reliability and longevity are essential.

| Product Name: Inconel 718 pipe |

| Chemical Composition |

| Grade | C | Mn | Si | Fe | S | Cr | Al | Ni | |

| 718 | min. | – | – | – | bal | – | 17.0 | 0.2 | 50.0 |

| max. | 0.08 | 0.35 | 0.35 | bal | 0.01 | 21.0 | 0.8 | 55.0 | |

| Mechanical Properties | Tensile Strength: Up to 220 ksi (Approx. 1500 MPa) |

| Yield Strength: Up to 185 ksi (Approx. 1250 MPa) | |

| Elongation: 12-25% | |

| Brinell Hardness: Up to 331 HBW | |

| Impact Resistance: Dependent on temperature and annealing treatment |

| Thermal Properties | Melting Range: 2675-2760°F (Approx. 1475-1520°C) |

| Thermal Conductivity: 7.9 W/m°C at 20°C | |

| Thermal Expansion: Approx. 11.0 x 10^-6 m/m°C in the temperature range -250°C to +700°C |