How hard is 430 stainless steel?

06-20-2024

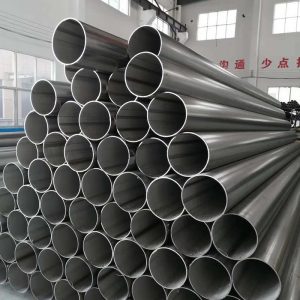

As a metal material widely used in various industrial and living fields, stainless steel has a wide variety of types, each type has its unique physical and chemical properties. Among them, 430 stainless steel has been widely used in many occasions because of its good corrosion resistance, processability and relatively low cost. So, how about the hardness of 430 stainless steel?

The basic composition of 430 stainless steel

430 stainless steel is a ferritic stainless steel, mainly composed of iron, chromium, nickel and a small amount of carbon. Among them, the chromium content determines the corrosion resistance of stainless steel, while the nickel content affects its hardness and toughness. The relatively low nickel content in 430 stainless steel gives it good plasticity and processability, but it also means that its hardness may not be as good as some other types of stainless steel.

In terms of hardness

430 stainless steel is a medium-hardness stainless steel material. Its relatively low hardness makes it easy to process and shape, which is suitable for the production of various parts and products with complex shapes. However, this also means that the wear resistance and scratch resistance of 430 stainless steel is relatively weak, and it is not suitable for occasions where high hardness and high wear resistance are required.

Specific application scenarios of 430 stainless steel

It is precisely because of its lower hardness and good processing properties that 430 stainless steel has been widely used in some specific fields. For example, in the field of construction, 430 stainless steel is often used in interior decoration, kitchenware, bathroom facilities and so on. Its smooth surface and easy to clean properties make it an ideal material for these fields. In addition, in the automotive, home appliances and other industries, 430 stainless steel is also favored for its price advantages and good processing properties.

Of course, for applications with high hardness requirements, such as tools, bearings, etc., other types of high-strength stainless steel may need to be selected. These stainless steels can obtain higher hardness and better wear resistance by optimizing the composition and heat treatment process.

Conclusion

The hardness of 430 stainless steel is relatively low, but its unique performance and reasonable price make it have a wide range of application prospects in some specific fields. When selecting stainless steel materials, the performance characteristics of hardness, corrosion resistance, processing performance and so on should be weighed according to the actual needs and application scenarios.