What is the composition of ASTM A312 material?

05-28-2024

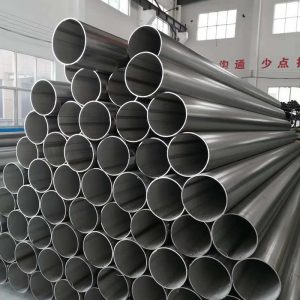

ASTM A312 is a widely used standard that specifies manufacturing requirements for seamless and welded austenitic stainless steel pipes. These tubes play a key role in a variety of industrial applications, especially in environments that require high corrosion resistance and high temperature stability. To understand the properties and application scenarios of ASTM A312 materials, you first need to have a deep understanding of their composition.

First of all, the stainless steel pipe under the ASTM A312 standard is mainly made of stainless steel, its composition mainly includes iron (Fe), chromium (Cr), nickel (Ni) and other elements, as well as a small amount of other alloying elements such as molybdenum (Mo), titanium (Ti) and so on. The content and proportion of these elements play a decisive role in the performance of stainless steel.

Chromium is one of the most important alloying elements in stainless steel, which protects stainless steel from further corrosion by combining with oxygen to form a dense oxide film. Nickel improves the toughness and corrosion resistance of stainless steel, especially in high temperature and strong acid environments. The addition of other alloying elements such as molybdenum and titanium can further improve the corrosion resistance, high temperature resistance and strength of stainless steel.

According to the ASTM A312 standard, stainless steel pipes can be divided into many types according to the specific composition and heat treatment method, such as austenitic stainless steel, ferritic stainless steel and martensitic stainless steel. These different types of stainless steel tubes differ slightly in their chemical composition, which leads to differences in their performance and application.

Austenitic stainless steel is the most common type, which has good corrosion resistance, toughness and processing properties, and is widely used in chemical, petroleum, pharmaceutical, food processing and other fields. Ferritic stainless steel has high strength and good stress corrosion resistance, suitable for high temperature and high pressure environment. Martensitic stainless steel has high hardness and wear resistance, and is often used in the manufacture of tools and bearings.

In general, the composition of ASTM A312 material depends mainly on the composition and type of stainless steel, and the ratio of these elements and alloys makes stainless steel pipes have excellent corrosion resistance, high strength and good processing properties. When choosing ASTM A312 stainless steel pipe, it is necessary to select the appropriate material type and specification according to the specific application environment and requirements. At the same time, in the process of manufacturing and use, it is also necessary to strictly comply with relevant standards and specifications to ensure the safe, stable and reliable operation of the pipeline system.

In addition, with the continuous progress of science and technology and the rapid development of industry, the performance and quality requirements for ASTM A312 stainless steel pipes are also constantly improving. Therefore, for manufacturers, it is necessary to continuously optimize the production process and technology to improve the purity and uniformity of materials to meet the growing demand of the market.

In short, the composition of ASTM A312 material is a complex and critical issue, which is directly related to the performance and application range of stainless steel pipes. Through in-depth understanding of its constituent elements and types, we can better select and use this high-quality material to provide strong support for the development of the industrial field.