What thickness do stainless steel sheets come in?

05-13-2024

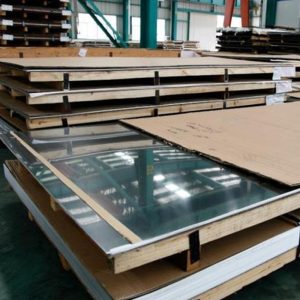

Stainless steel plate, with its excellent corrosion resistance, high strength and good processability, is widely used in construction, chemical, medical, food and other fields. However, in the selection of stainless steel plate, in addition to considering its material, surface treatment and other factors, the thickness specification is also an important parameter that cannot be ignored.

The thickness specifications of stainless steel sheets can be customized according to specific needs and applications. Common thicknesses range from 0.3 mm to 100 mm, covering a wide selection from thin sheets to thick sheets. This diversity allows stainless steel sheets to adapt to a variety of complex engineering needs.

In the thinner specification range, stainless steel sheet is mainly used in decoration, furniture manufacturing, kitchenware and other fields. These applications require materials that are both strong and beautiful in appearance. The thin stainless steel sheet can meet these requirements well, and because of its lightweight characteristics, it is also convenient for transportation and installation.

With the increase in thickness, the strength and durability of the stainless steel sheet will also be improved accordingly. Thicker plates are usually used for structural projects such as buildings, Bridges, and ships. In these applications, stainless steel sheets need to withstand greater pressure and weight, so they must have sufficient strength and stability. In addition, thick stainless steel sheet is also widely used in chemical, petroleum, food and other industries, for the manufacture of corrosion resistant, high temperature resistant equipment and pipelines.

The thickness specification of stainless steel sheet is also affected by the production process and cost. Thinner sheets are usually produced by a cold rolling process, while thicker sheets may be hot-rolled or other processes. Different production processes will have a certain impact on the performance and appearance of the plate. At the same time, different thickness specifications will also lead to differences in material costs, and customers need to weigh in according to actual needs and budgets when choosing stainless steel sheets.

In short, stainless steel sheet thickness specifications are diverse, to meet the needs of different industries and applications. Choosing the right thickness specification is important to ensure material properties, reduce costs and improve engineering efficiency. With the continuous progress of technology and the changing market demand, the thickness specifications of stainless steel sheets will continue to develop and improve to adapt to more complex and diverse application scenarios.

In the selection of stainless steel sheet, in addition to considering the thickness specifications, but also need to pay attention to its material, surface treatment, welding performance and other aspects. Different stainless steel materials have different corrosion resistance and mechanical properties, and the surface treatment will affect their appearance and durability. In addition, weldability is also an important consideration, especially in engineering projects that require welded connections.

In the future, with the continuous progress of science and technology and the continuous expansion of the market, the thickness specifications of stainless steel sheets will be more abundant and perfect. At the same time, with the improvement of environmental awareness and the requirements of sustainable development, the production of stainless steel sheet will also pay more attention to environmental protection and energy saving. This will help promote the healthy development of the stainless steel plate industry and provide more high-quality and efficient stainless steel materials for all walks of life.

In summary, the thickness specifications of stainless steel sheet are diverse and important, and choosing the right specifications is of great significance to ensure project quality and reduce costs. In the selection of stainless steel sheet, it is necessary to comprehensively consider its thickness, material, surface treatment, welding performance and other factors to meet the actual needs and improve engineering efficiency.